Oct . 03, 2024 05:21 Back to list

Top Suppliers of Hydraulic Oil Seals for Reliable Performance and Quality

Hydraulic Oil Seal Suppliers The Key to Reliable Hydraulic Systems

In the world of hydraulics, the efficiency and reliability of the system are paramount. At the core of many hydraulic applications lies the hydraulic oil seal, which plays a crucial role in preventing fluid leakage and maintaining pressure. With the increasing demand for hydraulic systems in various industries—ranging from construction and manufacturing to automotive and aerospace—the need for high-quality hydraulic oil seals has never been more critical. This article seeks to explore the importance of hydraulic oil seal suppliers and what to consider when choosing one.

Understanding Hydraulic Oil Seals

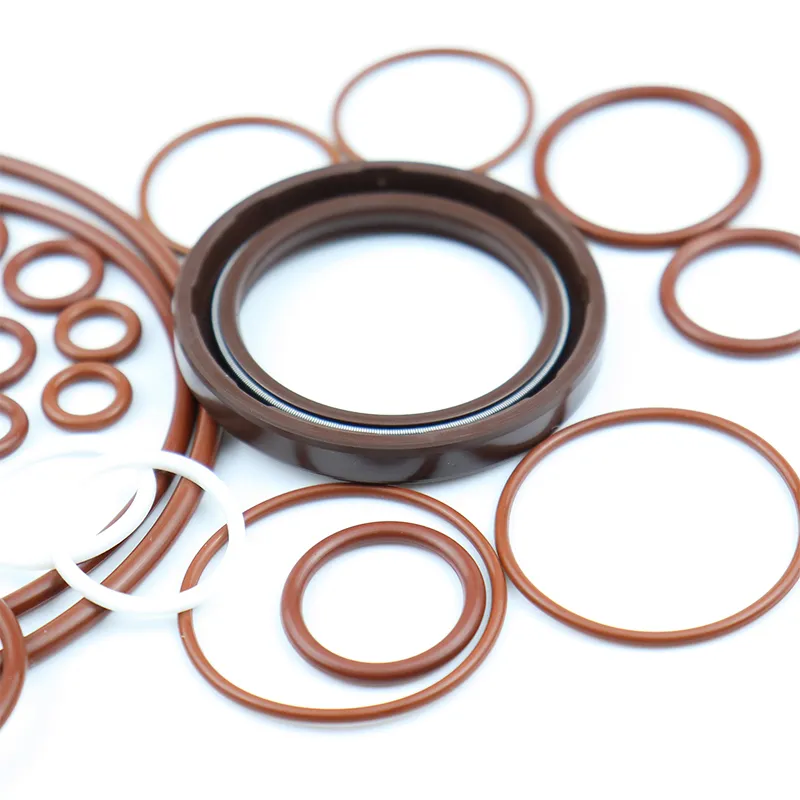

Hydraulic oil seals are designed to retain hydraulic fluids and prevent them from leaking out of hydraulic cylinders and systems. They play a vital role in ensuring that the hydraulic system operates efficiently, as even a minor leak can lead to significant drops in performance, increased maintenance costs, and potential damage to machinery.

These seals are made from various materials, including rubber, polyurethane, and PTFE, each contributing distinct properties such as flexibility, temperature resistance, and durability. Given their critical function, sourcing quality hydraulic oil seals is essential for the longevity and reliability of hydraulic systems.

The Role of Hydraulic Oil Seal Suppliers

Hydraulic oil seal suppliers are responsible for providing manufacturers and industries with the seals they need to keep their hydraulic systems operating smoothly. The selection of a reliable supplier can have a significant impact on the quality of the seals and, consequently, the performance of the hydraulic systems. Here are several factors to consider when choosing hydraulic oil seal suppliers

1. Quality Assurance

The foremost consideration should be the quality of the seals. Reliable suppliers often adhere to stringent quality control measures and comply with international standards. They should be able to provide documentation and certifications that guarantee the quality and reliability of their products.

Different hydraulic applications require different seal materials. A reputable supplier will offer a variety of materials suited to specific needs, such as high temperatures, harsh chemicals, or unique pressure situations. Ensure that the supplier can meet your specific requirements and offer expert advice on the best options available.

3. Customization Options

hydraulic oil seal suppliers

In many cases, standard seals may not fit the unique specifications of a hydraulic application. A good supplier should offer customization options to create seals tailored to your exact needs. This could involve altering dimensions, materials, or design features to ensure optimal performance.

4. Technical Support and Expertise

Hydraulic systems can be complex, and issues may arise that require expert guidance. Suppliers with extensive knowledge about their products can provide valuable support, helping you select the right oil seals, troubleshoot problems, or optimize performance.

5. Reliability and Timeliness

When you need hydraulic oil seals, you often need them quickly to avoid costly downtime. A reliable supplier should have a proven track record of timely deliveries. Check reviews, testimonials, and case studies to gauge their performance in meeting deadlines.

6. Cost Competitiveness

While quality should never be compromised for cost savings, it is still vital to find a supplier that offers competitive pricing. Compare prices from multiple suppliers but ensure that inclusions like shipping, customization, and warranty policies are factored into the overall cost.

7. Sustainability Practices

In today’s market, many companies prioritize sustainability. Suppliers that utilize eco-friendly materials and sustainable manufacturing practices can be a great choice if this is a priority for your organization.

Conclusion

Choosing the right hydraulic oil seal supplier is essential for the performance and reliability of hydraulic systems. By considering factors such as quality assurance, material variety, customization options, technical support, reliability, cost competitiveness, and sustainability practices, you can ensure that your hydraulic equipment operates at peak performance. Investing in high-quality hydraulic oil seals from a reputable supplier not only enhances efficiency but also extends the lifespan of your machinery, ultimately leading to increased productivity and reduced operational costs. As industries continue to evolve, the importance of selecting dependable hydraulic oil seal suppliers remains a key element in maintaining robust hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories