Dec . 09, 2024 19:41 Back to list

Choosing the Right Sizes for Hydraulic Oil Seals in Machinery Applications

Understanding Hydraulic Oil Seal Sizes A Comprehensive Guide

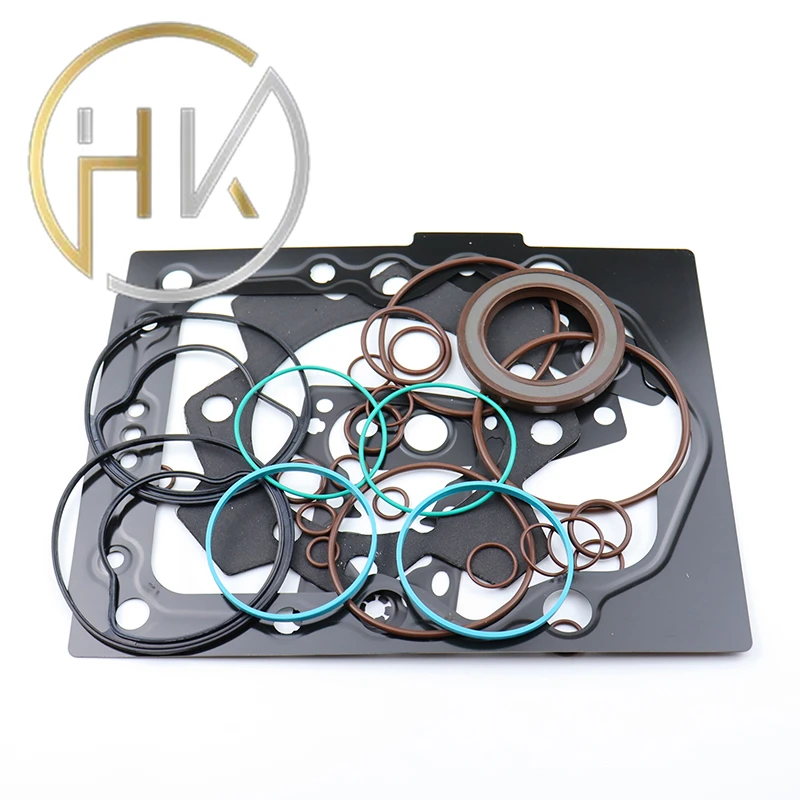

Hydraulic systems are essential components in various industrial, automotive, and aerospace applications. They rely on hydraulic oil seals to prevent leaks, maintain pressure, and ensure system efficiency. An understanding of hydraulic oil seal sizes is crucial for selecting the right seals for your specific application and ensuring optimal performance. This article delves into the importance of hydraulic oil seal sizes and how to choose them effectively.

Importance of Hydraulic Oil Seals

Hydraulic oil seals serve as barriers that prevent hydraulic fluids from escaping the system. They are critical in maintaining the hydraulic pressure necessary for the system to function. A properly sized and well-installed oil seal can significantly reduce wear and tear on components, enhance safety, and prolong the life of hydraulic machinery. Conversely, using an improperly sized or damaged seal can lead to leaks, increased maintenance costs, and potential system failures.

Hydraulic Oil Seal Sizes Explained

The size of a hydraulic oil seal is determined by several key dimensions, including the inner diameter (ID), outer diameter (OD), and thickness

. These dimensions are critical for ensuring a proper fit and function within the hydraulic system.1. Inner Diameter (ID) This is the diameter of the hole that the seal will fit onto. It must match the shaft size precisely. If the ID is too large, it will not provide adequate sealing, leading to leaks.

2. Outer Diameter (OD) This is the diameter of the seal that fits into the housing or bore. Similar to the ID, the OD must be appropriate for the housing size. An incorrect OD can prevent the seal from making contact with the housing, compromising the seal's effectiveness.

3. Thickness Also known as the cross-section of the seal, thickness is crucial for providing adequate sealing force against the surfaces it is designed to seal. An insufficient thickness can result in a weak seal that fails under pressure.

Choosing the Right Size

hydraulic oil seal sizes

To select the correct hydraulic oil seal size, follow these steps

- Identify the Manufacturer's Specifications Refer to the equipment manual or datasheets provided by the manufacturer. These documents usually specify the exact dimensions required for sealing applications.

- Measure Existing Seals If a replacement is necessary, measure the dimensions of the existing seal accurately. Use calipers for precise measurements to ensure that you get the right sizes.

- Consult with Suppliers Many suppliers have comprehensive catalogs or tools that allow you to input dimensions and find suitable seals. They can also provide guidance on material choices and performance characteristics based on your application.

- Consider the Operating Conditions The environment in which the hydraulic system operates can influence seal selection. Factors such as temperature, pressure, and fluid compatibility must be considered. Oil seals are made from different materials, including nitrile rubber, fluorocarbon, and polyurethane, each with its advantages and limitations in particular conditions.

Common Sizes and Applications

Hydraulic oil seals are available in a vast range of sizes to accommodate various applications. Common sizes include metric and imperial measurements, with many seals produced to standard specifications. For example, seals with IDs ranging from 10 mm to 100 mm and ODs from 20 mm to 120 mm are frequently used in hydraulic cylinders and pumps.

Industrial applications such as manufacturing machinery, construction equipment, and automotive hydraulics typically rely on specific size seals tailored for specific equipment. Additionally, custom sizes can be manufactured for unique applications that do not fit standard dimensions.

Conclusion

In conclusion, understanding hydraulic oil seal sizes is essential for maintaining the efficiency and reliability of hydraulic systems. Accurate measurements of ID, OD, and thickness are critical to ensure a proper fit and effective sealing. By following best practices for seal selection and being aware of the operating conditions, users can prevent leaks and extend the lifespan of their hydraulic equipment. Investing in the right hydraulic oil seals not only ensures operational efficiency but also contributes to the overall safety and reliability of hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories