Dec . 07, 2024 12:56 Back to list

hydraulic oil seal price

Understanding the Pricing of Hydraulic Oil Seals

Hydraulic oil seals are vital components used in hydraulic systems to prevent fluid leakage and contamination, ensuring the efficient operation of machinery and equipment. As the demand for hydraulic systems continues to rise across various industries—including construction, automotive, and manufacturing—the pricing of hydraulic oil seals becomes a critical factor for manufacturers, suppliers, and end-users. In this article, we will explore the factors influencing the price of hydraulic oil seals, market trends, and considerations for both buyers and sellers.

Factors Influencing Prices

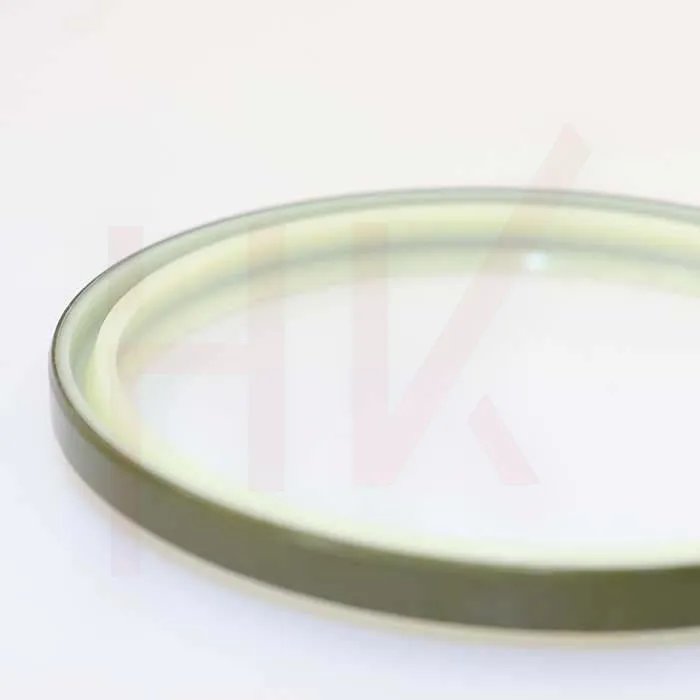

1. Material Composition The material used in the production of hydraulic oil seals significantly affects their pricing. Common materials include Nitrile Rubber (Buna-N), Fluorocarbon (Viton), Silicone, and Polyurethane. Each material has distinct properties, such as temperature resistance, chemical compatibility, and durability, which can alter costs. For instance, Viton seals, known for their superior resistance to high temperatures and aggressive chemicals, are generally more expensive than standard Nitrile seals.

2. Design and Specifications The complexity of the seal’s design plays a crucial role in determining its price. Custom seals manufactured to specific dimensions or with unique features, such as multi-lip designs or integrated backup rings, will naturally command a higher price than standard off-the-shelf options. Precision engineering required for these bespoke products increases manufacturing costs, ultimately impacting the final price.

3. Manufacturing Processes The production techniques employed to create hydraulic oil seals also contribute to price variations. Advanced methods, such as injection molding or precision machining, can increase production costs compared to simpler methods, such as compression molding. Moreover, economies of scale come into play; larger orders generally lower the per-unit cost due to reduced overhead and improved production efficiency.

4. Market Demand and Supply Like any other commodity, the price of hydraulic oil seals is also influenced by market dynamics of supply and demand. In periods where demand surges—perhaps due to an uptick in construction projects—the prices may rise accordingly. Conversely, a decline in demand can lead to reduced prices as manufacturers seek to move inventory. Seasonal fluctuations can also play a role, with some industries experiencing predictable cycles of higher activity.

hydraulic oil seal price

5. Brand Reputation Brand plays a significant role in pricing as well. Established manufacturers with a reputation for high quality and reliability often price their products higher than less known brands. End-users may be willing to pay a premium for seals from reputable manufacturers to mitigate risks associated with failures that could lead to downtime or costly repairs.

Current Market Trends

In recent years, there has been a noticeable shift towards sustainability in the manufacturing of hydraulic seals. Manufacturers are increasingly looking for eco-friendly materials and practices, which, while potentially raising costs, appeal to environmentally-conscious consumers. Additionally, the adoption of advanced technologies, such as 3D printing and smart manufacturing techniques, is beginning to influence pricing structures, offering a potential for cost reduction in the long term.

Buying Considerations

For purchasing agents and engineers, understanding the factors that influence hydraulic oil seal prices is crucial for making informed buying decisions. It’s essential to balance cost with performance and reliability. While opting for cheaper alternatives might seem appealing initially, long-term reliability and the costs associated with potential failures must be factored in.

Conclusion

In summary, the price of hydraulic oil seals is influenced by a multitude of factors, including material composition, design complexity, manufacturing processes, market dynamics, and brand reputation. As industries continue to evolve and demand for hydraulic systems grows, understanding these elements will be essential for both buyers and sellers. By staying informed about market trends and considering long-term performance, stakeholders can make more strategic decisions that align with their operational goals and budget constraints.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories