Nov . 22, 2024 14:19 Back to list

hydraulic oil seal material

The Importance of Hydraulic Oil Seal Materials

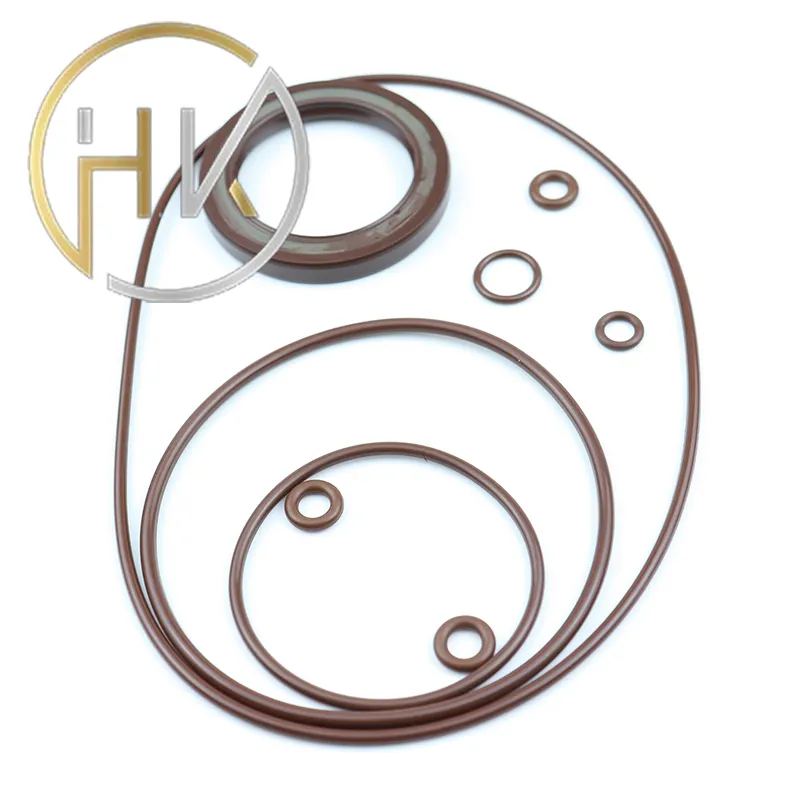

Hydraulic systems are integral components in various industrial and automotive applications. One of the crucial elements that ensure the effectiveness of these systems is the hydraulic oil seal. The oil seal serves to prevent the leakage of hydraulic fluid and contamination from external elements, thereby maintaining system efficiency and longevity. Given their significance, understanding the materials used for hydraulic oil seals is essential for selecting the right components for any hydraulic system.

Common Materials Used in Hydraulic Oil Seals

1. Nitrile Rubber (NBR) Nitrile rubber is one of the most widely used materials for hydraulic oil seals. It offers excellent resistance to oils, fuels, and certain chemicals, making it suitable for various hydraulic oils. NBR seals also provide good elasticity and mechanical properties, ensuring a tight seal under pressure. They can withstand temperatures ranging from -30°C to 100°C, depending on the specific formulation. However, NBR may deteriorate when exposed to high temperatures or certain aggressive chemicals.

2. Polyurethane (PU) Polyurethane seals are known for their superior abrasion resistance and resilience, making them ideal for demanding applications. They can tolerate a broader temperature range, typically from -40°C to 90°C, and possess excellent wear resistance. This material is often preferred in environments with high mechanical stress or exposure to aggressive hydraulic fluids. However, polyurethane can be sensitive to moisture, so care must be taken in environments with high water exposure.

3. Fluoroelastomer (FKM) Fluoroelastomers, such as Viton, are increasingly popular for hydraulic oil seals due to their exceptional chemical resistance and high-temperature tolerance. FKM seals can operate in temperatures up to 200°C and maintain their integrity even when exposed to harsh chemicals and environments. While they provide excellent sealing performance, they tend to be more expensive than other materials, making them suitable for specialized applications where performance is paramount.

4. Silicone Rubber Silicone rubber is another option, particularly in applications that require flexibility and resistance to extreme temperatures. Silicone seals can operate in a range of -60°C to 200°C and provide good resistance to weathering and ozone exposure. However, their mechanical strength is lower than that of other materials, which may limit their use in high-pressure applications.

Factors to Consider When Choosing Seal Materials

hydraulic oil seal material

When selecting the appropriate hydraulic oil seal material, several factors must be taken into consideration

- Chemical Compatibility Ensure the seal material is compatible with the hydraulic fluid being used. Different fluids have varying chemical compositions that can affect the seal’s performance and longevity.

- Temperature Range Evaluate the operational temperature range of the hydraulic system. Select materials that can maintain sealing integrity within the expected operational temperatures.

- Pressure Conditions Consider the pressure conditions that the hydraulic system will experience. Some materials perform better under higher pressures than others.

- Environmental Conditions Analyze the environmental conditions the seals will face, including exposure to moisture, dust, and extreme temperatures. This can greatly influence the durability and performance of the seals.

Conclusion

Selecting the right material for hydraulic oil seals is crucial for maintaining the efficiency and reliability of hydraulic systems. By understanding the properties of common seal materials such as nitrile rubber, polyurethane, fluoroelastomer, and silicone rubber, engineers can make informed decisions that minimize leakage, reduce maintenance costs, and extend the lifespan of hydraulic machinery. As technology advances and new materials emerge, staying updated on these developments will further enhance the performance of hydraulic systems across various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories