Dec . 10, 2024 16:58 Back to list

hydraulic oil seal manufacturers

Understanding Hydraulic Oil Seal Manufacturers

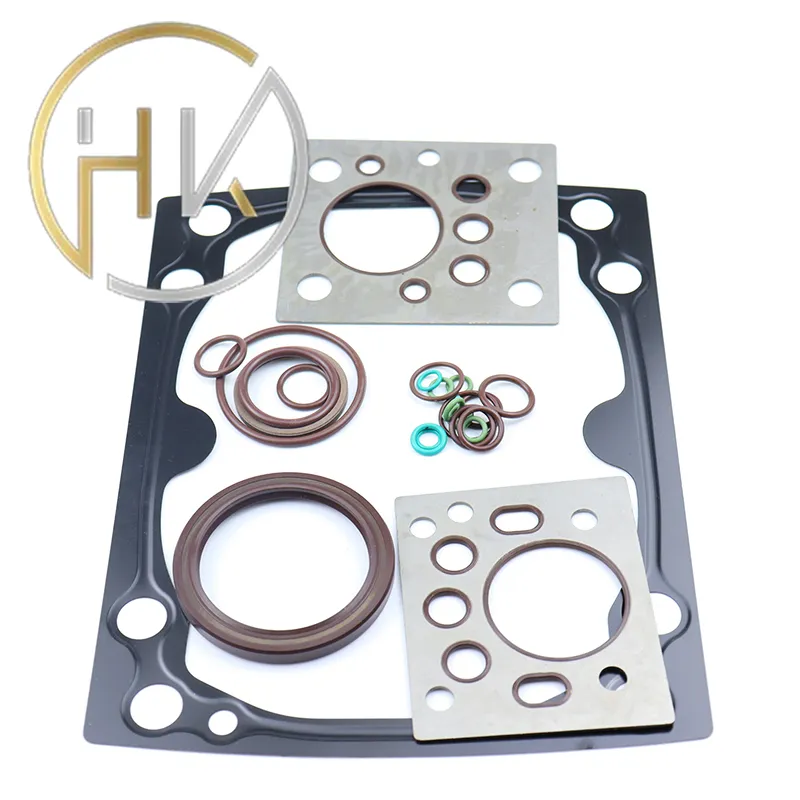

Hydraulic oil seals are vital components in hydraulic systems, serving to prevent the leakage of hydraulic fluid while keeping contaminants out. Given their critical role in ensuring the efficiency and longevity of hydraulic machinery, the selection of a reliable manufacturer for these seals is essential. This article explores the landscape of hydraulic oil seal manufacturers, their products, and the factors to consider when choosing the right one.

Importance of Hydraulic Oil Seals

Hydraulic oil seals facilitate the smooth operation of various machinery and systems, including construction equipment, manufacturing machinery, and automotive applications. They are designed to withstand high pressures, resist wear, and adhere to strict industry standards. A well-manufactured oil seal provides a reliable barrier against hydraulic fluid leakage, which not only helps to maintain system pressure but also prevents environmental contamination.

Types of Hydraulic Oil Seals

Manufacturers offer a diverse range of hydraulic oil seals tailored for different applications. The most common types include

1. U-Cups These seals have a U-shaped profile and are effective in preventing fluid leakage in both static and dynamic applications. They are widely used in rods and pistons in hydraulic cylinders.

2. O-Rings O-rings are versatile seals that can be used in a variety of configurations and are often employed in static applications. They come in various materials to suit different temperatures and chemical exposures.

3. V-Rings V-rings are designed to provide a sealing solution where there’s little axial space. They are capable of offering protection against dust and moisture, making them ideal for certain hydraulic applications.

4. Lip Seals These seals feature a flexible lip that contacts the shaft, effectively preventing fluid leakage. They are commonly used in rotating equipment.

hydraulic oil seal manufacturers

Choosing the Right Manufacturer

Selecting a hydraulic oil seal manufacturer involves multiple considerations to ensure the quality and performance of the seals. Here are key factors to consider

1. Reputation and Experience Research the manufacturer’s history and reputation within the industry. A company with years of experience and a proven track record is more likely to provide quality products.

2. Quality Control Inquire about the manufacturer’s quality control processes. Certifications such as ISO 9001 indicate adherence to international quality standards, ensuring that the products meet the required specifications.

3. Material Options Different hydraulic applications may require seals made from specific materials, such as nitrile, polyurethane, or fluorocarbon. A good manufacturer should offer a variety of materials to accommodate various application needs.

4. Customization Every application has its unique requirements. Manufacturers that can provide custom seals tailored to specific dimensions and performance characteristics can offer significant advantages.

5. Technical Support A manufacturer that provides access to technical resources and support can be invaluable. This assistance can ensure proper installation and troubleshooting, which enhances the longevity of the seal and the efficiency of the system.

6. Cost and Value While price is an important factor, it shouldn’t be the only consideration. Evaluate the overall value, including product quality, durability, and after-sale service, rather than focusing solely on the lowest price.

Conclusion

Hydraulic oil seal manufacturers play a crucial role in the efficiency and reliability of hydraulic systems. By understanding the types of seals available and the criteria for selecting a manufacturer, businesses can make informed decisions that enhance operational performance and reduce maintenance costs. The right hydraulic oil seals not only prevent leaks and contamination but also contribute to the overall productivity and longevity of hydraulic machinery.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories