Nov . 18, 2024 15:13 Back to list

Hydraulic Oil Seal Suppliers and Their Key Roles in Industrial Applications

The Role of Hydraulic Oil Seal Manufacturers in Modern Industries

Hydraulic oil seals play a crucial role in various industrial applications, ensuring the efficient operation of hydraulic systems. As technology evolves, the need for high-quality hydraulic oil seals has become imperative. This is where hydraulic oil seal manufacturers step in, providing products that meet the demanding standards of modern machinery and equipment.

Understanding Hydraulic Oil Seals

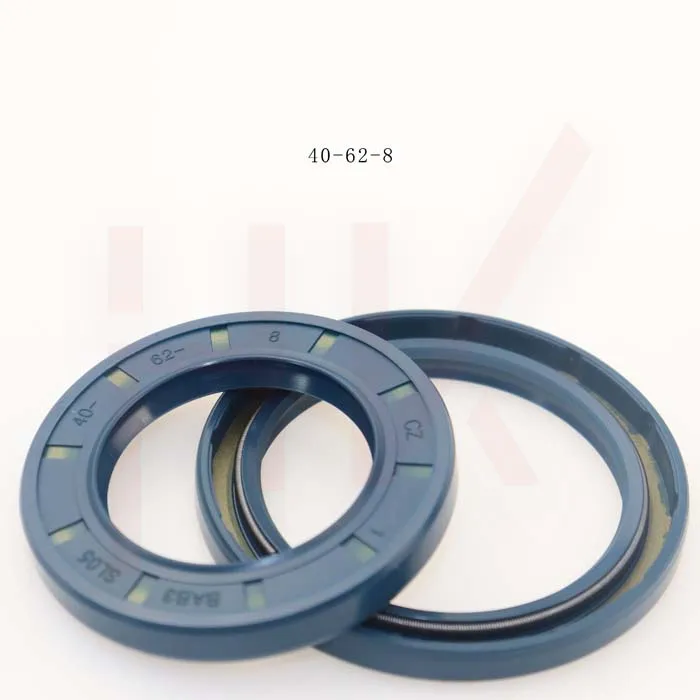

Before delving into the significance of manufacturers, it is essential to understand what hydraulic oil seals are. These are specialized components designed to prevent the leakage of hydraulic fluid in various applications, protecting internal mechanisms from contamination and ensuring optimal performance. They are predominantly made from materials such as elastomers, metals, and plastics, each selected based on the specific requirements of the application, including factors such as temperature, pressure, and chemical exposure.

Importance of Quality Manufacturing

The performance of hydraulic systems relies heavily on the integrity of the seals used. Poor-quality seals can lead to leaks, decreased efficiency, and ultimately, equipment failure. Therefore, the expertise of hydraulic oil seal manufacturers is paramount. High-quality manufacturers invest in advanced technologies and materials to produce seals that can withstand extreme environments and high-pressure conditions.

These manufacturers conduct rigorous testing to ensure that their seals meet the necessary industry standards, such as those laid out by the International Organization for Standardization (ISO). From material selection to precise manufacturing processes, quality control is a critical aspect of hydraulic oil seal production.

Key Features of Reliable Oil Seal Manufacturers

When choosing hydraulic oil seal manufacturers, several key features should be considered

1. Expertise and Experience Manufacturers with years of experience are more likely to understand the intricacies involved in producing reliable seals. They can leverage their knowledge to offer innovative solutions tailored to specific industry needs.

hydraulic oil seal manufacturers

2. Diverse Product Range A reputable manufacturer should provide a wide variety of oil seals to cater to different applications. This diversity allows customers to find the perfect fit for their unique hydraulic systems.

3. Customization Capabilities The ability to customize oil seals based on specific requirements is a vital feature. Manufacturers that can create seals tailored to the unique specifications of their clients’ equipment demonstrate their commitment to quality and customer satisfaction.

4. Advanced Technology and Materials Manufacturers who invest in research and development can provide products made from advanced materials that offer better performance and durability. This is crucial in industries such as automotive, aerospace, and construction, where failure of hydraulic systems can result in significant downtime and financial loss.

5. Strong Customer Support A good manufacturer should offer robust customer support. This includes guidance on product selection, assistance with installation, and prompt responses to queries and issues.

Market Trends and Future Directions

The hydraulic oil seal manufacturing industry is undergoing several changes driven by technological advancements and increasing environmental concerns. There is a rising demand for seals made from environmentally friendly materials that do not compromise on performance. Manufacturers that embrace sustainable practices not only contribute to environmental protection but also enhance their market appeal.

Additionally, the integration of smart technologies into hydraulic systems is leading to new requirements for oil seals. Manufacturers are increasingly focusing on developing seals that can withstand the challenges posed by advanced hydraulic systems, which may include increased pressure and temperature variations.

Conclusion

In conclusion, hydraulic oil seal manufacturers are vital to the efficiency and reliability of hydraulic systems across various industries. Their commitment to quality, innovation, and customer satisfaction directly impacts the longevity and performance of machinery. As the industry continues to evolve, these manufacturers play a crucial role in shaping the future of hydraulic technology. By understanding the importance of selecting the right hydraulic oil seal manufacturer, businesses can ensure their operations remain efficient, sustainable, and successful.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories