Nov . 16, 2024 03:37 Back to list

Top Manufacturers of Hydraulic Oil Seals for Superior Performance and Reliability

Understanding Hydraulic Oil Seal Manufacturers

Hydraulic oil seals play a crucial role in various industrial applications, ensuring the efficient operation of hydraulic systems. As the demand for reliable hydraulic systems continues to grow, the importance of choosing the right manufacturers for hydraulic oil seals becomes paramount. This article delves into the key aspects of hydraulic oil seal manufacturers, their offerings, and the factors to consider when selecting a supplier.

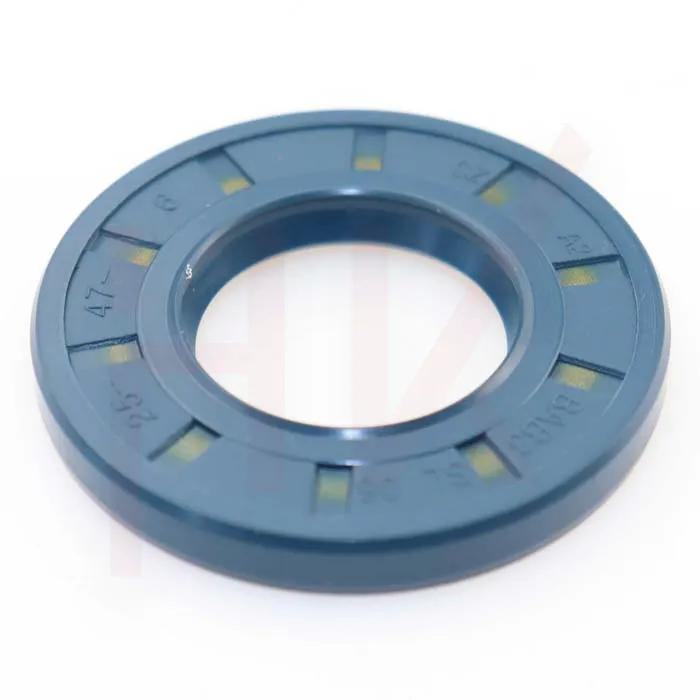

Hydraulic oil seals are designed to prevent hydraulic fluid from leaking out of hydraulic systems while simultaneously keeping contaminants from entering. These seals are essential in maintaining pressure and improving the overall efficiency of machinery, such as excavators, forklifts, and other hydraulic equipment. The quality of the oil seals significantly impacts the performance and longevity of the hydraulic system, which is why sourcing them from reputable manufacturers is essential.

When considering hydraulic oil seal manufacturers, it’s important to evaluate their product range. A reliable manufacturer should offer a wide variety of seals tailored for different applications and specifications. These may include various materials, such as Nitrile, Viton, and polyurethane, each suited for specific operating conditions. The ability to customize seals to meet unique requirements is another sign of a competent manufacturer, as it demonstrates their commitment to customer satisfaction and product performance.

hydraulic oil seal manufacturers

The manufacturing process is another critical aspect to consider. Manufacturers who invest in advanced technologies and adhere to strict quality control measures are more likely to produce high-quality hydraulic oil seals. Certifications, such as ISO 9001, can indicate that a manufacturer has established a quality management system, ensuring consistent product delivery.

Additionally, the expertise of the manufacturer’s engineering team is crucial. A knowledgeable team can assist customers in selecting the appropriate seals for their specific applications, providing valuable insights into compatibility with different fluids and operational pressures. This technical support can be indispensable in preventing system failures and optimizing performance.

Moreover, customer service plays an important role in the selection process. A manufacturer that prioritizes communication and support, offering quick response times and assistance with inquiries, can enhance the overall purchasing experience. Timely delivery and reasonable pricing are also important factors that contribute to customer satisfaction.

In conclusion, hydraulic oil seal manufacturers are vital in ensuring the performance and reliability of hydraulic systems. By considering the range of products offered, manufacturing processes, engineering expertise, and customer service, businesses can make informed decisions when selecting their suppliers. Ultimately, partnering with reputable manufacturers will contribute to the efficiency and longevity of hydraulic machinery, driving productivity in various industries.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories