Sep . 28, 2024 21:05 Back to list

Top Manufacturers of Hydraulic Oil Seals for Industrial Applications and Machinery

Hydraulic Oil Seal Manufacturers Key Players in Fluid Power Technology

In the world of hydraulic machinery, the importance of reliable components cannot be overstated. Among these components, hydraulic oil seals play a crucial role in ensuring the efficient operation of hydraulic systems. As the demand for high-performance hydraulic systems continues to grow across various sectors, the need for high-quality hydraulic oil seal manufacturers also rises.

Understanding Hydraulic Oil Seals

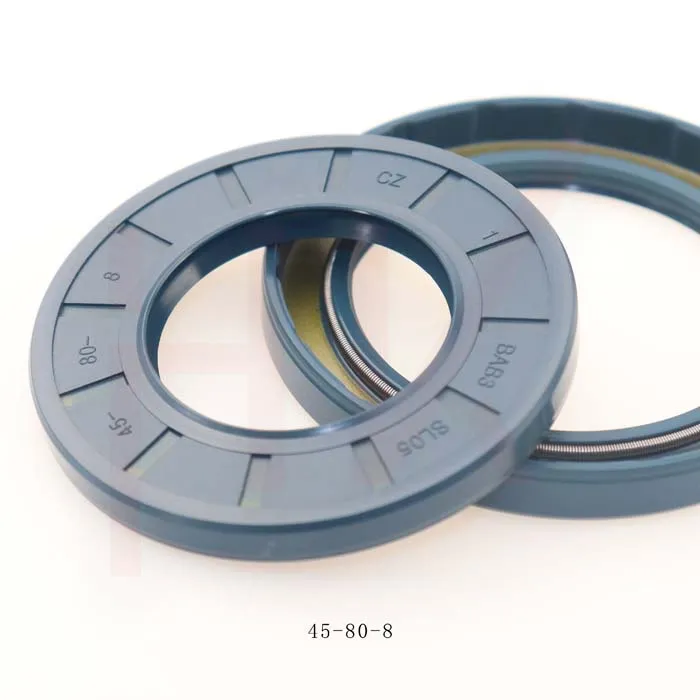

Hydraulic oil seals are designed to prevent the leakage of hydraulic fluids, thus maintaining the integrity and efficiency of hydraulic systems. These seals are typically made from materials that can withstand substantial pressure and temperature fluctuations. Common materials include rubber, polyurethane, and PTFE (polytetrafluoroethylene), each offering unique benefits based on the specific application.

The functionality of hydraulic seals is critical; any failure can lead to fluid leaks, loss of pressure, and even catastrophic system failures. This underscores the importance of sourcing seals from reputable manufacturers who understand the intricacies of hydraulic systems and material science.

The Role of Manufacturers

Hydraulic oil seal manufacturers are tasked with designing and producing seals that meet the varying needs of different industries, including automotive, construction, aerospace, and manufacturing. These manufacturers invest heavily in research and development to innovate and enhance the performance of their products.

Leading manufacturers often offer a wide range of seals, including O-rings, backup rings, and custom seals tailored to specific applications. Quality assurance processes are integral to their operations, with rigorous testing protocols in place to ensure that seals withstand harsh conditions.

Key Considerations When Choosing a Manufacturer

When selecting a hydraulic oil seal manufacturer, several factors should be taken into account

hydraulic oil seal manufacturers

1. Quality Standards Look for manufacturers that adhere to international quality standards, such as ISO certifications. High-quality seals are essential for preventing leaks and ensuring system reliability.

2. Material Options Different applications require different materials. A manufacturer that offers a diverse range of material options can better serve the varied needs of their clients.

3. Customization Capabilities For specialized applications, the ability to customize seals is crucial. Manufacturers that can develop bespoke solutions often have a competitive edge.

4. Experience and Reputation Longevity and a strong reputation in the industry can be indicators of a manufacturer’s reliability. Researching customer reviews and industry feedback can provide insights into a manufacturer’s performance.

5. Support and Service Good customer service and technical support are vital. Manufacturers should be willing to assist with product selection and troubleshooting to ensure optimal performance.

Emerging Trends in Hydraulic Seal Manufacturing

The hydraulic seal manufacturing industry is evolving with advancements in technology and materials science. Manufacturers are increasingly exploring the use of eco-friendly materials to reduce environmental impact. Additionally, the integration of smart technologies, such as sensors within seals to monitor their condition, is an emerging trend that promises to enhance system reliability.

Moreover, automation in the manufacturing process is streamlining production, reducing costs, and improving precision, which is essential for high-demand applications. As industries continue to expand and evolve, so too will the technology and methodologies employed by hydraulic oil seal manufacturers.

Conclusion

Hydraulic oil seal manufacturers are integral to the fluid power industry, providing critical components that ensure the functionality and reliability of hydraulic systems. By understanding the key roles these manufacturers play and what to consider when choosing one, businesses can better secure the performance of their hydraulic machinery. With ongoing advancements in materials and technology, the future of hydraulic oil seals looks promising, aligning with the demands of ever-evolving industrial applications.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories