Nov . 27, 2024 10:08 Back to list

Hydraulic Motor Repair Kit for Efficient Rebuilding and Maintenance Solutions

Understanding Hydraulic Motor Rebuild Kits A Comprehensive Guide

Hydraulic motors are vital components in various industrial applications, utilizing hydraulic fluid to produce rotational motion. Over time, these motors can wear down due to factors such as improper maintenance, contamination, or simply old age. One effective way to extend the life of your hydraulic motor is through the use of a rebuild kit. In this article, we will explore what a hydraulic motor rebuild kit is, its components, benefits, and installation tips.

What is a Hydraulic Motor Rebuild Kit?

A hydraulic motor rebuild kit is a collection of parts designed to restore the functionality of a malfunctioning hydraulic motor. These kits typically include the essential components needed for a comprehensive overhaul. The specific contents can vary based on the motor model, but they commonly feature seals, O-rings, bearings, and other critical components necessary for efficient operation.

Components of a Hydraulic Motor Rebuild Kit

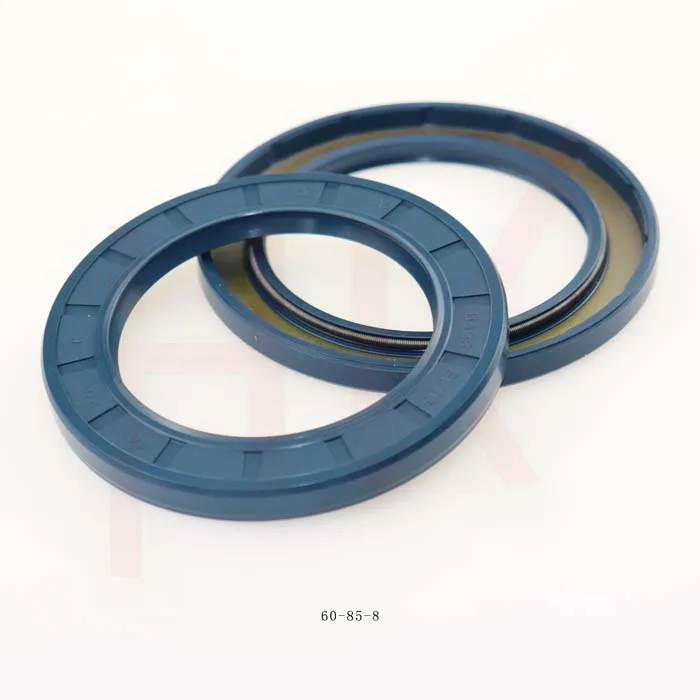

1. Seals and O-Rings These are crucial for preventing hydraulic fluid leaks. Over time, seals can become brittle and crack, leading to reduced efficiency and potential contamination of the hydraulic system.

2. Bearings Bearings support the shaft and reduce friction during operation. Worn bearings can cause vibrations, excessive heat, and further damage to the motor.

3. Gaskets Gaskets provide a seal between different parts of the motor. Replacing gaskets is essential when rebuilding to ensure a tight seal that will prevent leaks.

4. Shaft Kits In some kits, you may find complete shaft assemblies that include various components designed for specific applications. This is particularly useful in saving time and ensuring a perfect fit.

5. Miscellaneous Parts Depending on the motor's design and application, additional components like bushings and retainer clips may also be included.

Benefits of Using a Rebuild Kit

1. Cost-Effective Rather than purchasing a brand-new motor, which can be quite expensive, a rebuild kit can rejuvenate your existing motor at a fraction of the cost.

hydraulic motor rebuild kit

2. Improved Performance By replacing worn-out parts, you can restore optimum performance and efficiency to your hydraulic motor. This can lead to better productivity and reduced downtime.

3. Extended Equipment Life Regular maintenance and timely rebuilding can significantly extend the lifespan of your hydraulic motor, delaying the need for replacement.

4. Environmental Benefits Rebuilding existing equipment is more environmentally friendly than manufacturing new machines. It helps reduce waste and conserve resources.

5. Customization Rebuild kits offer the opportunity to customize your motor's performance. By selecting upgraded components, you can enhance capabilities tailored to your specific application requirements.

Installation Tips

1. Prepare a Clean Workspace Ensure that you have a clean area to work on your hydraulic motor. Dirt and contaminants can lead to further problems during and after the rebuild process.

2. Follow the Manual Always refer to the manufacturer’s service manual. It provides detailed instructions and specifications critical for the rebuild process.

3. Use the Right Tools Having the appropriate tools is crucial for a successful rebuild. Invest in quality tools that can handle the job without causing damage to the components.

4. Take Notes As you disassemble the motor, take notes or photographs to keep track of the order of parts. This helps avoid confusion during reassembly.

5. Test After Rebuilding Once the rebuild is complete, perform thorough testing to ensure everything is functioning as expected. Check for any leaks and monitor the motor's performance closely.

Conclusion

Hydraulic motor rebuild kits are invaluable for anyone looking to maintain or restore their hydraulic systems. By understanding the components and benefits of these kits, as well as following proper installation practices, you can enhance the performance and extend the lifespan of your hydraulic motors. Regular maintenance and timely rebuilds not only save costs but also contribute to a more sustainable approach to equipment management. Whether you are an industry professional or a DIY enthusiast, investing in a quality hydraulic motor rebuild kit is a step toward efficient and effective hydraulic system operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories