Jan . 19, 2025 01:58 Back to list

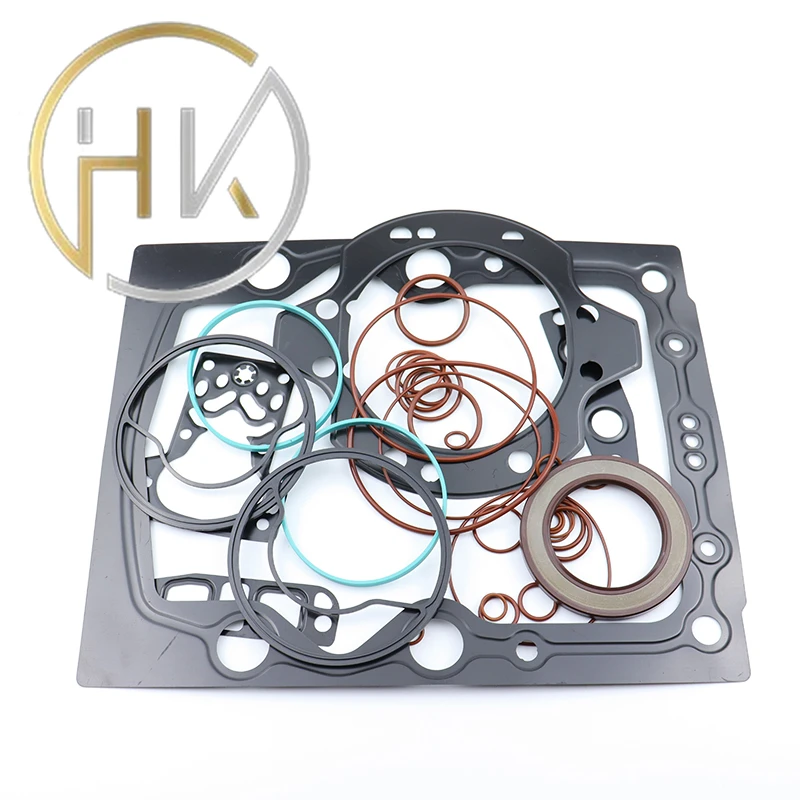

hydraulic lift cylinder seal kits

The authoritativeness of a guide on hydraulic lift cylinder seal kits lies in its alignment with industry standards and best practices. Professional bodies and manufacturers often set guidelines and standards that dictate the quality and compatibility of these kits. An authoritative article would draw from these standards, providing readers with insights into selecting the most reliable products that meet or exceed industry standards. A focus on brands with a proven track record can also illuminate paths towards optimal decisions, reinforcing the importance of purchasing from reputable manufacturers or suppliers. In terms of trustworthiness, firsthand testimonials and case studies from industry practitioners can instill confidence in prospective buyers. For example, a case study showcasing how a particular seal kit transformed the efficiency of a hydraulic system in a commercial setting offers invaluable insights and reassures potential customers of their purchasing decision. Additionally, transparent discussions about common issues, such as installation errors or maintenance lapses, further enhance trust by setting realistic expectations and providing solutions to rectify typical challenges. In essence, the deliberation on hydraulic lift cylinder seal kits is one that requires a blend of experience, expertise, authoritativeness, and trustworthiness. By placing emphasis on these facets, businesses and individuals can make informed choices that enhance the performance and longevity of their hydraulic systems.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories