Dec . 05, 2024 10:19 Back to list

Hydraulic Jack Seal Replacement Kit for Effective Repair and Maintenance Needs

Understanding Hydraulic Jack Seal Repair Kits A Comprehensive Guide

Hydraulic jacks are essential tools used in a variety of applications, from automotive repair to construction and heavy machinery lifting. Like any mechanical equipment, hydraulic jacks can experience wear and tear over time, particularly concerning their seals. This is where hydraulic jack seal repair kits come into play. In this article, we will delve into the importance of these kits, what they typically include, and how to use them effectively for maintenance and repairs.

The Importance of Hydraulic Jack Seals

The seals in a hydraulic jack serve a critical function. They prevent hydraulic fluid from leaking out of the cylinder, allowing the jack to build pressure and lift loads effectively. When seals fail, the jack may lose its lifting power and become inefficient or, worse, dangerous. Signs of seal failure can include visible leaks, diminished lifting ability, and the inability to hold a load once lifted.

Regular maintenance and timely replacement of seals can extend the life of your hydraulic jack, enhancing safety and reliability in operations. This is where a hydraulic jack seal repair kit becomes invaluable.

What’s Included in a Hydraulic Jack Seal Repair Kit?

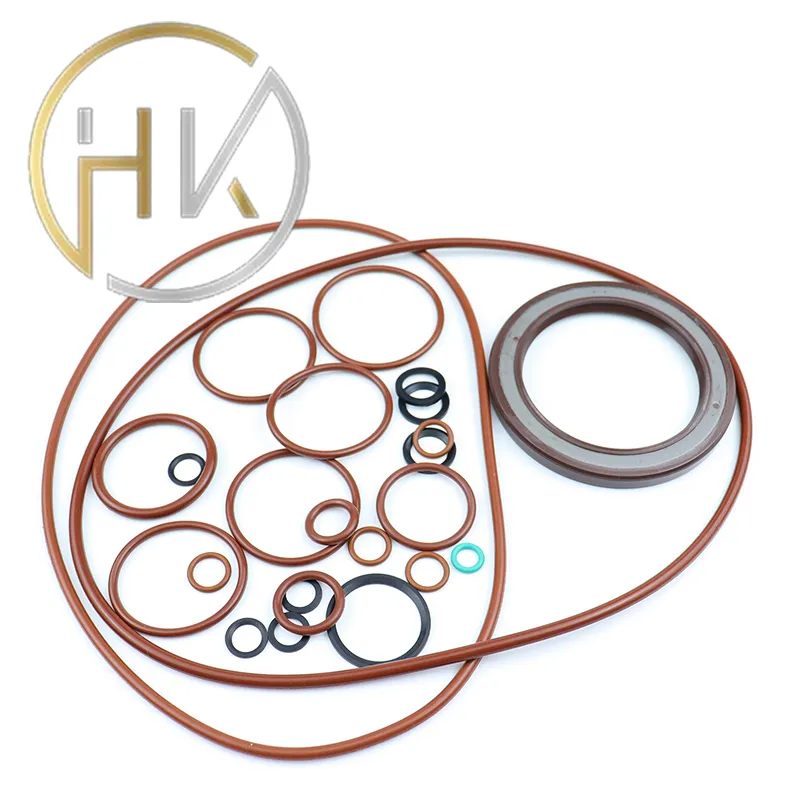

A hydraulic jack seal repair kit typically includes a variety of components necessary for restoring the functionality of your jack. Here are the common items you can expect to find in a typical kit

1. Seals and O-Rings The most crucial components of the kit, these seals are designed to fit specific hydraulic jack models. They come in various sizes and materials, typically rubber or polyurethane, to accommodate different pressure requirements and environmental conditions.

2. Piston Rings These rings help create a tight seal around the piston, ensuring that hydraulic fluid moves efficiently without leaking.

3. Hydraulic Fluid Some repair kits may include hydraulic fluid, which is necessary for the operation of the jack once the seals are replaced.

4. Assembly Tools Many kits also come with basic tools such as a wrench or a screwdriver to assist in the disassembly and reassembly process.

5. Instruction Manual A user-friendly guide detailing step-by-step instructions on how to replace the seals, ensuring that even novices can perform the repair.

hydraulic jack seal repair kit

Steps for Replacing Hydraulic Jack Seals

Replacing seals in a hydraulic jack may seem daunting, but with a bit of patience and the right tools, you can do it yourself. Here’s a simplified step-by-step guide

1. Prepare Your Workspace Ensure you have a clean and well-lit area to work. Gather all your tools and the repair kit components.

2. Drain Hydraulic Fluid Safely drain the hydraulic fluid from the jack. This is crucial as it minimizes mess and ensures safety.

3. Disassemble the Jack Carefully disassemble the jack according to the instruction manual. Keep track of all screws and components to avoid confusion during reassembly.

4. Remove Old Seals Take out the worn-out seals and inspect the pistons for any additional damage.

5. Install New Seals Apply a light coat of lubricant to the new seals and carefully install them in their designated grooves.

6. Reassemble the Jack Following the manual, reassemble the jack, ensuring that all components are properly aligned and tightened.

7. Refill Hydraulic Fluid Add fresh hydraulic fluid to the jack. Ensure it is the right type recommended for your jack.

8. Test the Jack Before putting it back to regular use, test the jack to ensure it operates correctly and that there are no leaks.

Conclusion

Hydraulic jack seal repair kits are essential for maintaining the integrity and functionality of hydraulic jacks. With the right components and a little know-how, you can extend the life of your hydraulic equipment significantly. Remember, proper maintenance not only saves money but also enhances safety during operation. By being proactive and utilizing repair kits, you can ensure that your hydraulic jacks remain reliable and efficient for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories