Dec . 04, 2024 16:53 Back to list

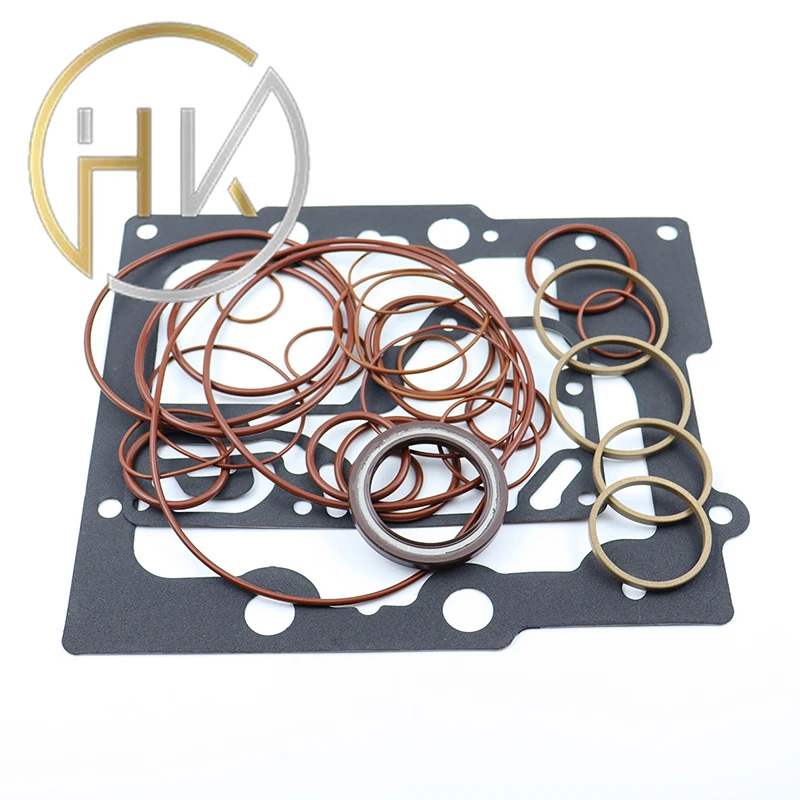

hydraulic cylinder wipers

Understanding Hydraulic Cylinder Wipers Essential Components for Performance and Longevity

In the world of hydraulic systems, the hydraulic cylinder is a key player, enabling powerful and precise movement in various applications, from industrial machinery to automotive systems. However, one often overlooked component that significantly influences the performance and longevity of hydraulic cylinders is the wiper.

What Are Hydraulic Cylinder Wipers?

Hydraulic cylinder wipers, also known as rod seals or dust seals, are integral components located at the external end of hydraulic cylinders. Their primary function is to prevent contaminants, such as dirt, dust, and moisture, from entering the cylinder and coming into contact with hydraulic fluid and internal components like the piston and seals. By safeguarding the interior from external elements, wipers help maintain the cylinder's operational efficiency and extend its lifespan.

The Importance of Wipers in Hydraulic Systems

1. Contamination Control The hydraulic fluid within a cylinder must remain uncontaminated to ensure smooth operation. Even minor contamination can lead to wear and tear of internal components, reducing efficiency and increasing maintenance costs. Wipers play a crucial role in keeping the hydraulic system clean by blocking foreign particles from entering.

2. Preventing Oil Leakage Wipers also help minimize oil leakage, which can occur when seals are worn or damaged. By ensuring that the sealing surfaces remain clean and free of debris, wipers assist in maintaining proper pressure within the system, thereby improving overall performance.

3. Reducing Wear and Tear Hydraulic cylinders experience considerable stress during operation. The presence of dust and particles can accelerate wear on the piston and cylinder walls. Well-functioning wipers reduce this risk by preventing contaminants from scratching or damaging critical surfaces, leading to enhanced durability.

4. Cost Efficiency Investing in quality hydraulic cylinder wipers can lead to long-term cost savings. By preventing damage and reducing maintenance needs, wipers help avoid costly repairs or replacements of hydraulic cylinders, thus ensuring more reliable operation in demanding applications.

Types of Hydraulic Cylinder Wipers

1. Single Acting Wipers These wipers are designed for applications where the cylinder only moves in one direction. They are typically simpler in design and are used in machines where back pressure is not a concern.

hydraulic cylinder wipers

2. Double Acting Wipers Used in cylinders that must function in both directions, double acting wipers provide a more robust seal and are essential for systems requiring bidirectional movement. They are engineered to handle greater stress and maintain seal integrity under varying pressures.

3. Metal Reinforced Wipers In conditions where extreme durability is required, metal reinforced wipers are employed. These wipers incorporate a metal skeleton to provide added strength and resistance to wear, making them suitable for heavy-duty applications.

4. U-Cups and V-Rings These are specific designs of wipers that accommodate different sealing requirements. U-cups are excellent for resisting back pressure, while V-rings offer flexibility and can adapt to various radial seal applications.

Choosing the Right Wiper

Selecting the appropriate hydraulic cylinder wiper involves considering several factors

- Material Wipers are made from various materials such as rubber, polyurethane, and sometimes PTFE (Teflon). The choice of material can influence resistance to temperature, pressure, and particular fluids.

- Compatibility Ensure the wiper is compatible with the specific hydraulic fluids used in the system. Certain materials may degrade in the presence of specific fluids or under high temperatures.

- Environmental Conditions Consider the operational environment. Applications exposed to extreme temperatures, humidity, or abrasive conditions may require specialized wipers.

- Application Type The choice will also depend on whether the hydraulic cylinder is used in a mobile, industrial, or static application.

Conclusion

Hydraulic cylinder wipers may seem like small components, but their role is critical in ensuring the efficiency, reliability, and longevity of hydraulic systems. By preventing contamination and minimizing wear, they help maintain the integrity of hydraulic operations. Investing in quality wipers and understanding their function can lead to substantial benefits in performance and cost-effectiveness in the long run. Whether in construction, manufacturing, or automotive sectors, proper maintenance and understanding of hydraulic cylinder wipers are vital for optimizing system performance.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories