Jan . 21, 2025 04:22 Back to list

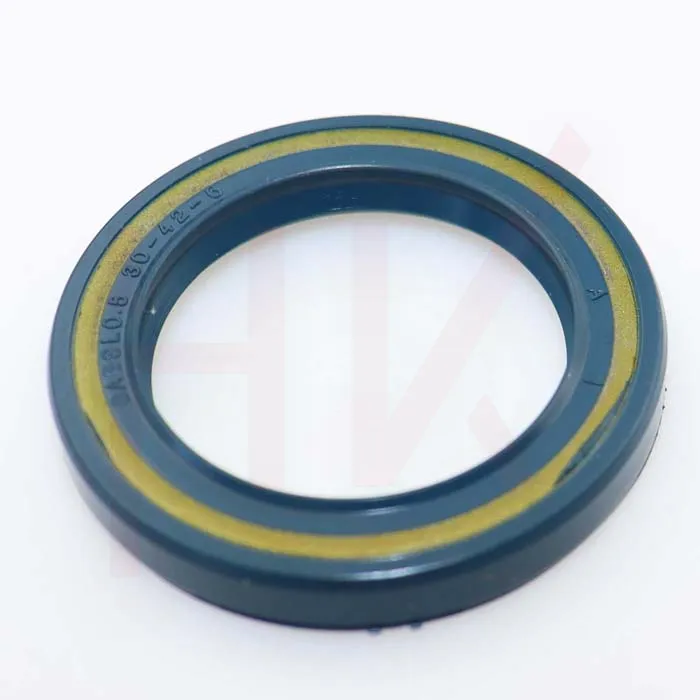

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

One must also consider the importance of maintenance and inspection routines. Even the best seals and wipers can suffer wear over time, leading to potential leaks or contamination. Establishing a stringent maintenance routine can preempt such issues, ensuring any wear is detected and addressed before it escalates into a significant problem. Trustworthiness and authority in the selection, maintenance, and replacement of hydraulic seals and wipers come from choosing suppliers and manufacturers with a proven track record. Brands that invest in research and development deliver cutting-edge seal technology, offering superior performance and reliability. Building a partnership with knowledgeable suppliers ensures you get access to both the best products and the expertise needed to use them effectively. Companies known for their authority in hydraulic components, deliver not just products but also insights and guidance on best practices, customization options, and troubleshooting advice, fostering trust and reliability in every transaction. Ultimately, making informed choices about hydraulic cylinder seals and wipers demands a blend of experience, technical knowledge, and an appreciation of operational demands. Elevating your understanding and approach in this domain not only maximizes equipment efficiency but also fortifies the integrity and safety of your hydraulic systems, establishing your enterprise as one that prioritizes precision and quality.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories