Nov . 25, 2024 14:58 Back to list

Hydraulic Cylinder Seals and Wipers for Optimal Performance and Longevity

Hydraulic Cylinder Seals and Wipers Essential Components for Optimal Performance

Hydraulic systems are fundamental in many industrial applications, playing a critical role in machinery and equipment. At the heart of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical power. To ensure the efficient operation and long lifespan of these cylinders, the use of seals and wipers is crucial.

Understanding Hydraulic Cylinder Seals

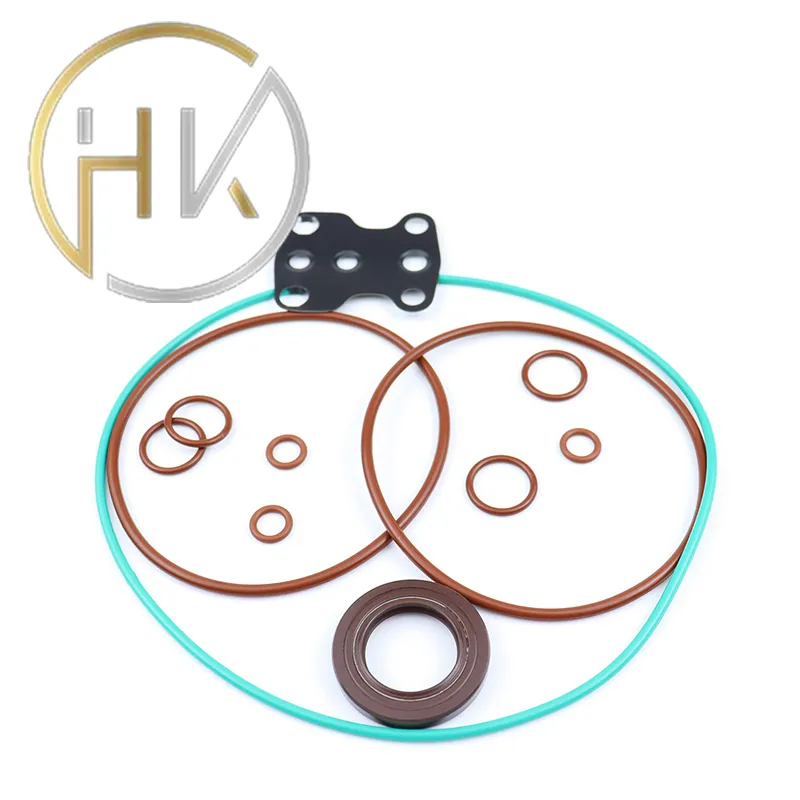

Hydraulic cylinder seals are designed to prevent fluid leaks while maintaining pressure within the cylinder. These seals are typically made from durable materials such as polyurethane, rubber, or PTFE, specifically engineered to withstand high pressures and varying temperatures. The primary function of hydraulic seals is to prevent hydraulic fluid from escaping the cylinder, which ensures efficient operation and minimizes the risk of environmental contamination.

There are various types of seals used in hydraulic cylinders, including piston seals, rod seals, and buffer seals. Piston seals are essential for creating a tight seal between the piston and the cylinder wall, allowing for maximum hydraulic pressure to be generated. Rod seals, on the other hand, serve to prevent fluid leakage where the piston rod exits the cylinder. Buffer seals provide additional protection against pressure spikes, enhancing the overall reliability of the hydraulic system.

hydraulic cylinder seals and wipers

The Role of Wipers in Hydraulic Cylinders

Wipers, also known as scraper seals, play a complementary role to seals in hydraulic cylinders. Their primary function is to keep contaminants, such as dirt, dust, and debris, out of the hydraulic cylinder. Contaminants can cause wear and tear on seals and other internal components, leading to premature failures and operational inefficiencies.

Wipers are typically positioned at the outer edge of the cylinder and are made from materials resistant to wear and environmental conditions. Their design allows them to effectively scrape away any debris that may accumulate on the rod as it moves in and out of the cylinder, thereby extending the life of the seals and overall hydraulic system.

Conclusion

In summary, hydraulic cylinder seals and wipers are integral components that ensure the effective functioning and longevity of hydraulic systems. By preventing fluid leakage and protecting against contamination, these components help maintain optimal performance, reduce downtime, and lower maintenance costs. Understanding the importance of these elements is essential for anyone involved in the operation and maintenance of hydraulic machinery, as they are key to achieving reliability and efficiency in various applications. Investing in high-quality seals and wipers is not just a choice; it is a necessity for maintaining the integrity of hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories