Oct . 14, 2024 01:36 Back to list

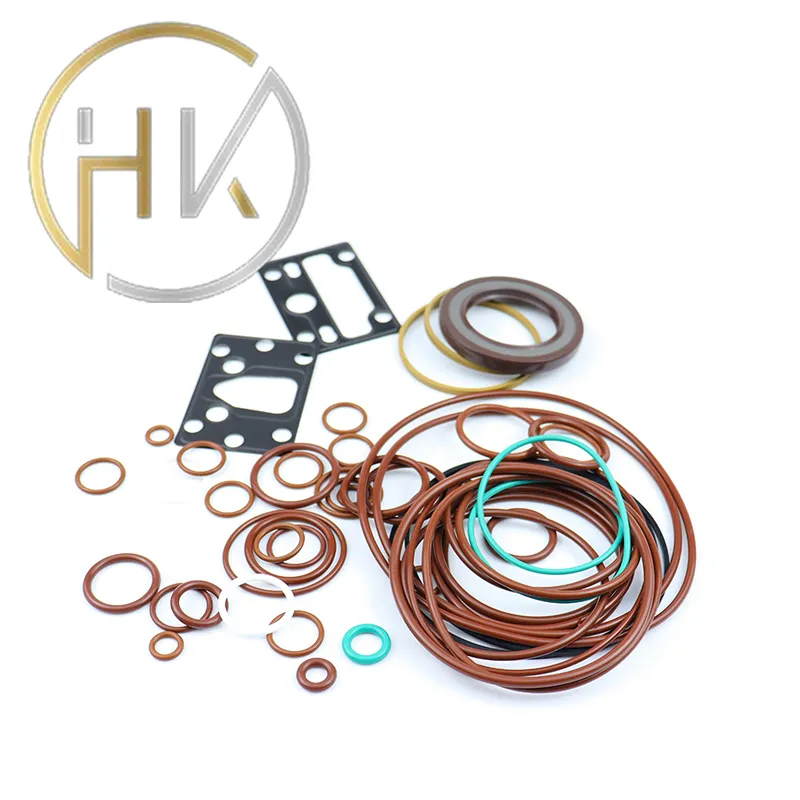

hydraulic cylinder seals and wipers

Understanding Hydraulic Cylinder Seals and Wipers Essential Components for System Longevity

Hydraulic systems are fundamental to various industrial applications, from construction machinery and manufacturing equipment to automotive hydraulics. At the heart of these systems lies the hydraulic cylinder, a device that converts hydraulic energy into mechanical work. However, the effectiveness and longevity of hydraulic cylinders heavily depend on their internal components, particularly seals and wipers. This article explores the roles of hydraulic cylinder seals and wipers, their types, and their importance in maintaining hydraulic system performance.

The Role of Hydraulic Cylinder Seals

Hydraulic cylinder seals are crucial components designed to prevent fluid leakage and ensure the efficient operation of the cylinder. They maintain the pressure necessary for the movement of the piston and rod, which in turn drives the machinery's operational functions. The primary types of seals used in hydraulic cylinders include

1. Static Seals These seals are used in areas where there is no relative motion between components. They help prevent fluid from escaping the hydraulic system and are typically easy to install.

2. Dynamic Seals Unlike static seals, dynamic seals are specifically designed for moving parts, such as the piston and rod within a hydraulic cylinder. They must be robust enough to withstand constant motion and the wear that comes with it. Common shapes for dynamic seals include O-rings and U-cups.

3. Buffer Seals These seals are used to absorb pressure spikes and protect the main seals from excessive wear. They are particularly useful in high-pressure applications.

The material composition of these seals is critical, often including elastomers such as Nitrile, Polyurethane, or even advanced materials like PTFE, which offer excellent resistance to wear, temperature fluctuations, and exposure to hydraulic fluids.

The Importance of Wipers

While seals keep hydraulic fluid contained, wipers, also known as scrapers, serve a different but equally essential function. Wipers are located on the exterior of the cylinder and are designed to keep the cylinder rod clean by scraping off dirt, debris, and other contaminants that may accumulate during operation. Contaminants can cause significant damage to the seal and the cylinder itself, leading to premature wear and failure.

hydraulic cylinder seals and wipers

There are several types of wipers, each tailored for specific applications and environmental conditions. For instance, flexible lip wipers are often used for their simple structure and effective sealing properties, while polyurethane wipers offer greater durability in harsh conditions.

Benefits of Proper Sealing and Wiping

The interplay between well-designed seals and effective wipers contributes directly to the longevity and reliability of hydraulic systems. Here are some of the key benefits

1. Leak Prevention Proper seals minimize the risk of hydraulic fluid leakage, ensuring efficient operation and reducing the loss of hydraulic pressure.

2. Reduced Maintenance Costs By preventing contamination and reducing wear on key components, effective wipers and seals can significantly lower maintenance and repair costs over time.

3. Enhanced Performance A well-sealed hydraulic cylinder maintains optimal performance levels, improving the efficiency of the machinery it powers.

4. Increased Safety Hydraulic fluid leaks pose significant safety hazards. Proper seals and wipers mitigate these risks, providing safer operating conditions for personnel.

5. Environmental Protection By controlling leaks, seals contribute to minimizing the environmental impact of hydraulic operations, aligning them with sustainability goals.

Conclusion

In summary, hydraulic cylinder seals and wipers are indispensable components that play vital roles in the operation and longevity of hydraulic systems. Understanding their functions and the materials used can help operators and maintenance personnel make informed decisions about their hydraulic systems' design and upkeep. Prioritizing the selection of high-quality seals and wipers not only ensures optimal performance but also enhances safety, reduces costs, and promotes environmental stewardship in hydraulic applications. As industries continue to advance, the importance of these components will only grow, emphasizing the need for continued innovation and improvement in hydraulic technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories