Dec . 10, 2024 03:38 Back to list

Exploring the Importance of Seals in Hydraulic Cylinder Performance and Longevity

Hydraulic Cylinder Seals An Essential Component in Hydraulic Systems

Hydraulic systems are ubiquitous in industries ranging from construction and manufacturing to aerospace and automotive. They rely on the power of fluid mechanics to transmit force and perform work. At the heart of these systems is the hydraulic cylinder, a device that converts hydraulic energy into mechanical energy. However, the efficiency and durability of hydraulic cylinders hinge significantly on a seemingly simple yet crucial component hydraulic cylinder seals.

Understanding Hydraulic Cylinder Seals

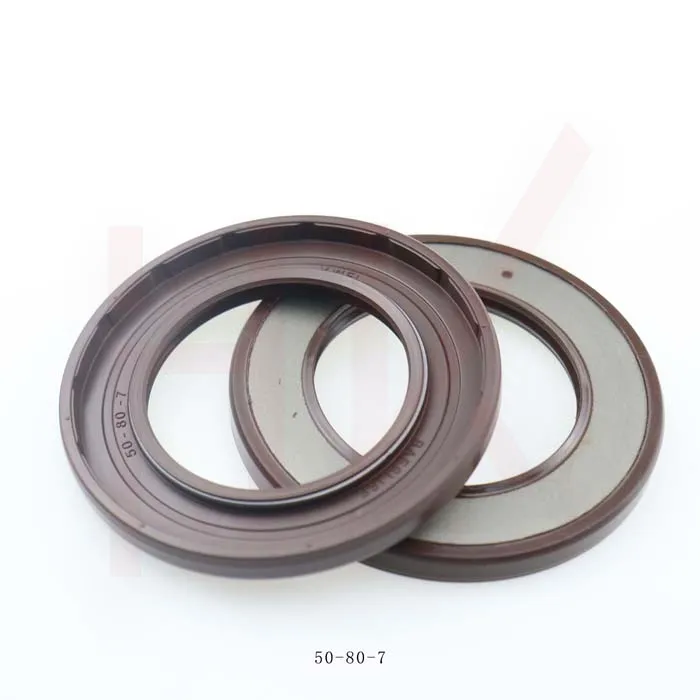

Hydraulic cylinder seals are specially designed components that prevent fluid leakage in hydraulic systems, while also keeping contaminants out of the system. They are typically made from materials that can withstand high pressures and resist wear, such as polyurethane, rubber, and PTFE (polytetrafluoroethylene). These seals come in various shapes and sizes, each designed for specific applications, making their selection critical for the overall performance of the hydraulic system.

Types of Hydraulic Cylinder Seals

There are several types of seals used in hydraulic cylinders, including

1. Rod Seals These seals are located at the end of the cylinder and are responsible for sealing the gap between the piston rod and the cylinder. They prevent hydraulic fluid from leaking out of the cylinder when the rod is in motion.

2. Piston Seals Found inside the cylinder, these seals ensure that hydraulic fluid does not bypass the piston. They are critical for maintaining the cylinder's pressure and ensuring effective operation.

3. Backup Rings These rings are used in conjunction with other seals to prevent extrusion of softer seal materials during high-pressure applications. They provide additional support and enhance the durability of the sealing solutions.

4. Static Seals These seals are used in areas where there is no relative motion between the sealing surfaces. They are typically found in flanged connections or between stationary components.

hydraulic cylinder seals

Importance of Proper Seal Selection

The performance, efficiency, and longevity of a hydraulic cylinder are largely dependent on the proper selection of seals. Factors such as pressure, temperature, fluid compatibility, and the presence of potential contaminants must be carefully considered when choosing seals. For instance, choosing the wrong material can lead to seal degradation, premature wear, and ultimately, system failure. Common issues include swelling, cracking, or tearing of seals, which can result in leaks and reduced efficiency.

Maintenance and Replacement

Regular maintenance is critical to extending the life of hydraulic cylinder seals. Operators should routinely inspect seals for signs of wear, damage, or leakage. Contaminants such as dirt and moisture can significantly compromise seal integrity, making it necessary to keep the hydraulic system clean. Additionally, it is essential to follow manufacturer recommendations for the frequency of seal replacement based on usage and operating conditions.

When replacing seals, it is crucial to use high-quality components that match the specifications of the original seals. Employing inferior seals can lead to recurring issues and increased costs due to frequent replacements.

Innovations in Seal Technology

The advancement in material science and engineering has led to innovative seal designs and materials that enhance the performance of hydraulic cylinder seals. Newer materials offer better resistance to wear and abrasion, higher temperature tolerances, and improved chemical resistance. Furthermore, advancements in sealing technologies, such as dynamic seals that can accommodate shaft movements, are expanding the capabilities and reliability of hydraulic systems.

Conclusion

In summary, hydraulic cylinder seals play a vital role in the efficiency and longevity of hydraulic systems. Their ability to prevent leaks, maintain pressure, and keep contaminants at bay is crucial for optimal performance. Understanding the types of seals available, ensuring proper selection, conducting regular maintenance, and keeping abreast of technological advancements are all essential steps in ensuring the reliability and effectiveness of hydraulic systems. As industries continue to evolve and push the boundaries of hydraulic applications, the importance of high-quality seals cannot be overstated in maintaining operational efficiency and safety.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories