Dec . 01, 2024 02:44 Back to list

hydraulic cylinder seal replacement

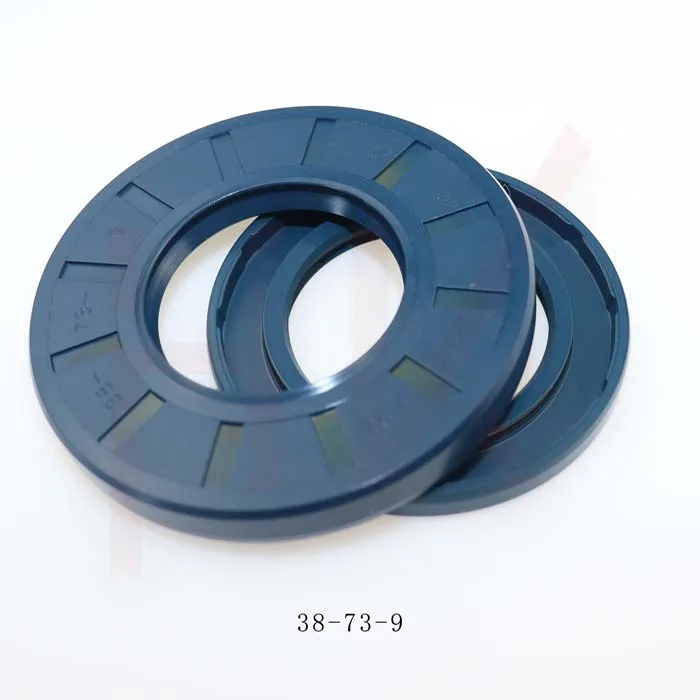

Hydraulic Cylinder Seal Replacement A Comprehensive Guide

Hydraulic cylinders play a crucial role in various industrial applications, providing the force needed for lifting, pushing, and pulling heavy loads. However, like all mechanical components, hydraulic cylinders can experience wear and tear over time, particularly in their seals. Seal failure can lead to hydraulic fluid leakage, decreased efficiency, and potentially severe equipment damage. In this article, we will explore the importance of hydraulic cylinder seal replacement, the signs of wear, and a step-by-step guide on how to perform this essential maintenance task.

Importance of Seal Replacement

The seals in hydraulic cylinders serve to contain the hydraulic fluid within the chamber, preventing leaks and maintaining pressure. They also reduce friction between moving parts, allowing for smooth operation. When these seals wear out, several issues may arise

1. Fluid Leaks One of the most noticeable signs of seal failure is leakage. Fluid escaping from the cylinder not only wastes resources but can also create safety hazards. 2. Loss of Pressure Worn seals can lead to a drop in hydraulic pressure, resulting in decreased performance. This can compromise the lifting capacity of machinery and lead to operational inefficiencies.

3. Component Damage Prolonged use of a hydraulic cylinder with worn seals can cause damage to other components, leading to costly repairs and downtime.

Signs of Worn Seals

Before proceeding with a seal replacement, it’s essential to identify the signs of wear. Look for

- Fluid Accumulation Puddles or drips of hydraulic fluid around the cylinder. - Decreased Performance Machinery operates sluggishly or fails to respond as expected. - Unusual Noises Grinding or whining sounds can indicate seal damage or internal wear.

Step-by-Step Guide to Seal Replacement

hydraulic cylinder seal replacement

1. Safety First Ensure that the equipment is turned off and depressurized. Wear appropriate personal protective equipment (PPE) such as gloves and goggles.

2. Disassemble the Cylinder Carefully remove the hydraulic cylinder from its mounting, taking note of how it is assembled. Use a suitable tool to unbolt and detach the cylinder from its housing.

3. Extract the Old Seals Once disassembled, you can access the seals. Use a seal removal tool to avoid damaging the cylinder walls. Take care to remember the arrangement of seals for reinstallation.

4. Clean the Components Thoroughly clean the cylinder and its components to remove any debris or residue. A clean working area is essential for a successful seal replacement.

5. Install New Seals Carefully position the new seals into their respective grooves. Be sure to lubricate them with applicable hydraulic fluid to ease installation and prevent damage.

6. Reassemble the Cylinder Following the order of disassembly, reassemble the hydraulic cylinder. Ensure all bolts are securely tightened as per manufacturer specifications.

7. Test the Cylinder Once reassembled, reconnect the cylinder to its mounting and fill it with hydraulic fluid. Test the system to ensure there are no leaks and that it operates smoothly.

Conclusion

Regular maintenance of hydraulic cylinders, particularly seal replacement, is vital for ensuring optimal performance and longevity of your equipment. By being proactive and attentive to signs of wear, you can prevent major issues and maintain the efficiency of your hydraulic systems. With the right knowledge and tools, seal replacement is a manageable task that can save time and expense in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories