Nov . 04, 2024 13:16 Back to list

Hydraulic Cylinder Seal Replacement Guide for Improved Performance and Longevity

Hydraulic Cylinder Seal Replacement A Comprehensive Guide

Hydraulic systems are crucial in various industries, from construction to manufacturing, providing the necessary force for heavy machinery and equipment. One essential component of these systems is the hydraulic cylinder, which uses pressurized fluid to create linear motion. However, over time, the seals in these cylinders can wear out, leading to leaks and inefficiencies. In this article, we will walk you through the process of hydraulic cylinder seal replacement, ensuring your systems run smoothly and efficiently.

Understanding Hydraulic Seals

Hydraulic seals serve a vital purpose in hydraulic systems. They prevent fluid leakage and maintain system pressure, ensuring that the hydraulic cylinder operates effectively. The seals can wear out due to several factors, including age, exposure to harsh environments, and chemical degradation from hydraulic fluids. When seals fail, you may notice oil leaks, reduced performance, and, ultimately, damage to the hydraulic cylinder itself.

Signs of Seal Failure

Recognizing the signs of seal failure early can save you time and money. Common indicators include

1. Visible Leaks Oil pooling around the cylinder indicates failing seals. 2. Loss of Pressure A decrease in system pressure can result from leaks, leading to diminished performance. 3. Increased Stroke Resistance Difficulty in movement when extending or retracting the cylinder may suggest internal damage or seal wear. 4. Noisy Operation Unusual sounds during operation could be a result of air entering the system due to faulty seals.

Preparing for Seal Replacement

Before you begin the seal replacement process, ensure you have the necessary tools and materials. You'll typically need

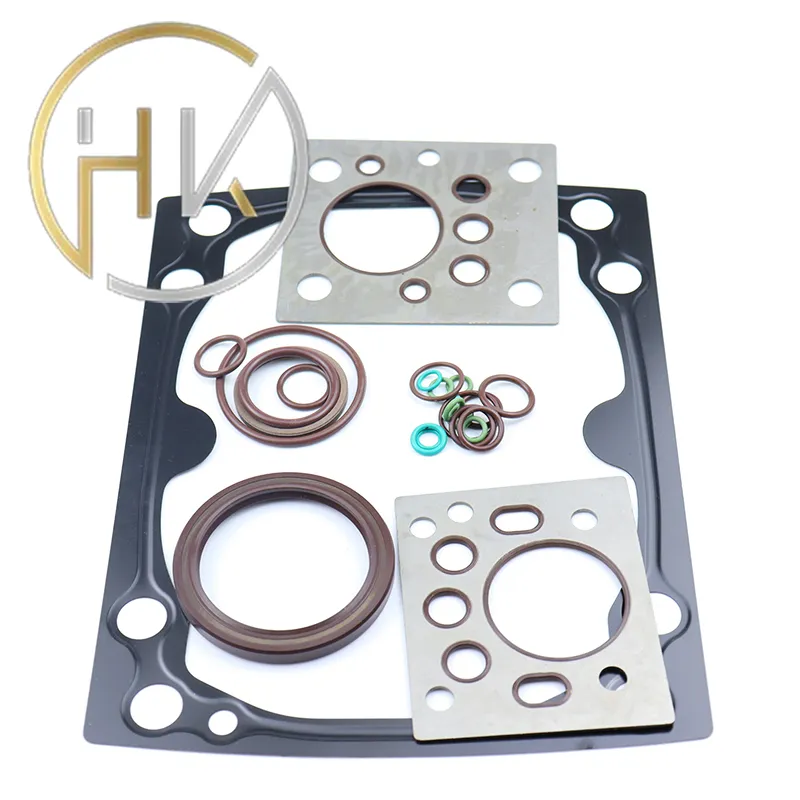

- Safety goggles and gloves - A wrench set - Screwdrivers - Seal pullers or installation tools - Replacement seal kit specific to your hydraulic cylinder model - Clean rags and degreaser - A torque wrench

Once you have your tools ready, follow the steps below for a successful seal replacement.

hydraulic cylinder seal replacement

Step-by-Step Seal Replacement Process

1. Safety First Before engaging in any maintenance work, ensure the hydraulic system is depressurized. Disconnect the power source and drain any hydraulic fluid from the cylinder.

2. Remove the Cylinder Detach the hydraulic cylinder from the machine it is connected to. This usually involves unbolting it from the mounting points and carefully maneuvering it out of its housing.

3. Disassemble the Cylinder Once you have the cylinder removed, carefully take it apart. This typically involves unscrewing the end caps and sliding out the piston. Keep track of how components fit together for reassembly.

4. Remove Old Seals With the cylinder disassembled, remove the old seals using a seal puller. Take care not to scratch the surfaces of the cylinder, as this can lead to further leaks.

5. Clean the Cylinder Components Thoroughly clean the cylinder and all components with a degreaser to remove any dirt, oil, or old sealant. Ensure all surfaces are smooth and free from damage.

6. Install New Seals Refer to the manufacturer's specifications when installing the new seals. Lubricate the seals with hydraulic oil to prevent them from tearing during installation. Use the correct tools to press the seals into their respective grooves carefully.

7. Reassemble the Cylinder Once the new seals are in place, reassemble the hydraulic cylinder by reversing the disassembly steps. Be sure to tighten all bolts securely, following recommended torque specifications.

8. Reconnect and Test After reassembly, reconnect the hydraulic cylinder to the machine, refill it with hydraulic fluid, and re-pressurize the system. Test the cylinder for proper operation, checking for leaks and ensuring smooth movement.

Conclusion

Performing a hydraulic cylinder seal replacement can seem daunting, but with the right tools and preparation, it is a manageable task. Regular maintenance and timely replacement of seals are essential to avoid downtime and costly repairs. By staying vigilant and adhering to safe practices, you can extend the life of your hydraulic equipment and ensure its optimal performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories