Jan . 20, 2025 14:33 Back to list

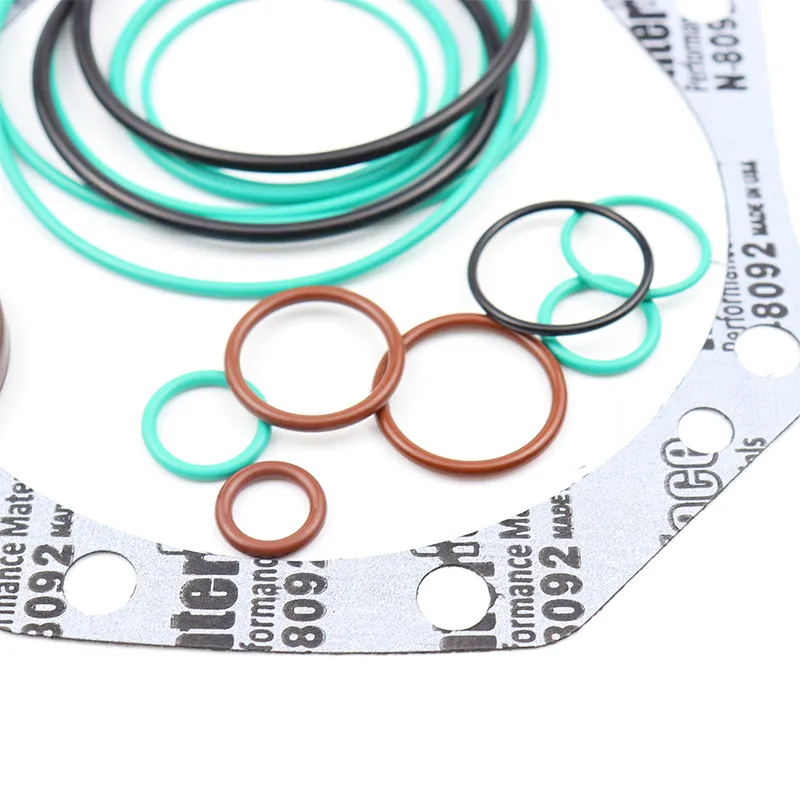

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

4. Cleaning Clean all metal components thoroughly to remove old lubricant and debris. Use a compatible cleaning solvent to ensure no contaminants remain, as they can impede seal performance. 5. Seal Replacement Measure the groove dimensions accurately and select appropriate seals. Lubricate the new seals lightly with hydraulic fluid to facilitate easier fitting. Carefully install the new seals, ensuring they are seated correctly without twisting. 6. Reassembly Align all components and reassemble the cylinder, using a torque wrench to tighten bolts to specified tolerances. This prevents over-tightening, which could damage the seals or the cylinder housing. 7. Testing Reattach the hydraulic cylinder to the system and run preliminary tests to check for leaks. Monitor the system under operational conditions to ensure that the repair is successful and the cylinder remains leak-free. Professional Tips for Prolonging Seal Life To extend the lifespan of hydraulic cylinder seals, adhere to a regular maintenance schedule. Regularly check for signs of wear and replace seals before they fail. Maintain an optimal operating environment for your machinery by avoiding excessive workloads and ensuring the hydraulic fluid remains clean and at the proper viscosity. Investing in high-quality seals and components pays off in the long run by minimizing system downtime and reducing repair costs. Conclusion The Expertise You Can Trust Repairing hydraulic cylinder seals is a precise task requiring technical knowledge and attention to detail. By following best practices and using the appropriate tools and materials, you can restore your machinery to peak performance, reducing downtime and extending equipment lifespan. For those unfamiliar with hydraulic systems, consulting a professional with experience in hydraulic maintenance is always a wise choice. Opting for expert services not only ensures effective repairs but also enhances the authority and trustworthiness of your operations in the competitive industrial landscape. Remember, maintaining a well-functioning hydraulic system is crucial to ensure the efficiency and reliability of your machinery, protecting your investment and ensuring operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories