Nov . 12, 2024 17:23 Back to list

hydraulic cylinder seal kits manufacturers

Hydraulic Cylinder Seal Kits Manufacturers Ensuring Efficiency and Reliability

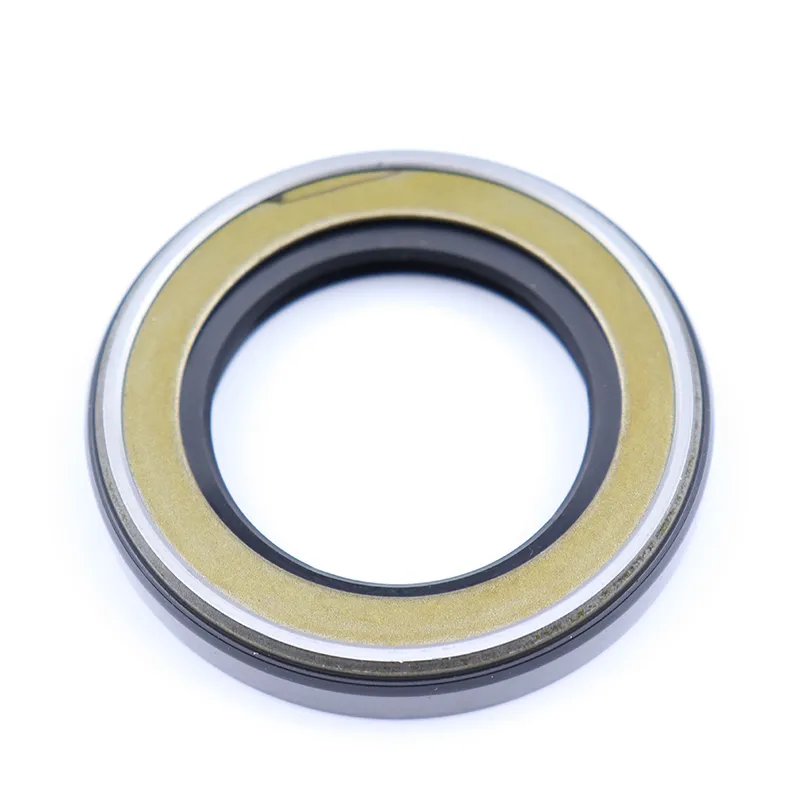

Hydraulic cylinders are fundamental components in various industrial applications, ranging from construction equipment to manufacturing machinery. The efficient operation of these cylinders largely depends on the quality of the seal kits used. Therefore, the role of hydraulic cylinder seal kits manufacturers is crucial in ensuring the reliability, longevity, and performance of hydraulic systems.

Seal kits are designed to prevent hydraulic fluid leaks, which can lead to significant operational failures, increased maintenance costs, and environmental hazards. Manufacturers of these seal kits focus on creating high-quality seals that can withstand extreme pressures, temperatures, and harsh environmental conditions. This involves using advanced materials and innovative design techniques that enhance the durability and effectiveness of the seals.

One of the primary materials used in the production of hydraulic seals is polyurethane, known for its excellent wear resistance and resilience against hydraulic fluids. Other materials such as nitrile rubber (NBR) and fluorocarbon (FKM) are also popular choices, each providing unique benefits depending on the specific application requirements. Manufacturers often customize seal kits to suit different hydraulic cylinder models and operational conditions, ensuring optimal performance and compatibility.

hydraulic cylinder seal kits manufacturers

Moreover, the manufacturing process involves stringent quality control measures. Leading manufacturers invest in state-of-the-art technology and equipment to produce seals that meet international standards. This commitment to quality not only enhances product reliability but also builds trust with customers, as they can be confident in the performance of the seal kits they purchase.

In addition to product quality, customer service and support are vital aspects of hydraulic cylinder seal kits manufacturers. Providing technical assistance, detailed product specifications, and timely delivery can significantly influence a purchaser's choice of supplier. Many manufacturers offer tailored solutions, allowing customers to find exactly what they need for their specific applications, whether it's off-the-shelf kits or custom solutions.

Furthermore, as industries move towards sustainability, the demand for environmentally friendly seal materials is on the rise. Manufacturers are responding by developing seals made from eco-friendly materials that minimize environmental impact while maintaining performance standards. This not only helps companies meet regulatory requirements but also appeals to environmentally conscious consumers.

In conclusion, hydraulic cylinder seal kits manufacturers play a pivotal role in the efficiency and reliability of hydraulic systems. By focusing on high-quality materials, advanced manufacturing processes, and excellent customer service, they ensure that the essential components of hydraulic machinery perform optimally. As industries evolve and face new challenges, these manufacturers will continue to innovate, providing solutions that enhance productivity while addressing sustainability concerns. The ongoing collaboration between manufacturers and their clients will be key in shaping the future of hydraulic technology.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories