Oct . 16, 2024 17:40 Back to list

Hydraulic Cylinder Seal Kit Suppliers for Reliable Performance and Durability

Understanding Hydraulic Cylinder Seal Kits A Guide for Manufacturers

Hydraulic systems are integral to modern machinery, providing the power required to perform various tasks across multiple industries, from construction to manufacturing. One of the essential components in these systems is the hydraulic cylinder, which relies on seal kits to function efficiently. This article aims to provide insights into hydraulic cylinder seal kits, their significance, and what manufacturers need to consider.

The Importance of Hydraulic Cylinder Seal Kits

Hydraulic cylinder seal kits are designed to prevent fluid leaks and maintain the pressure necessary for the operation of hydraulic systems. The seals within these kits are crucial for ensuring the smooth movement of the hydraulic cylinder’s piston, which in turn enables the machinery to perform its function effectively. Without high-quality seals, hydraulic fluid can escape, leading to decreased efficiency, increased wear and tear, and potential system failures.

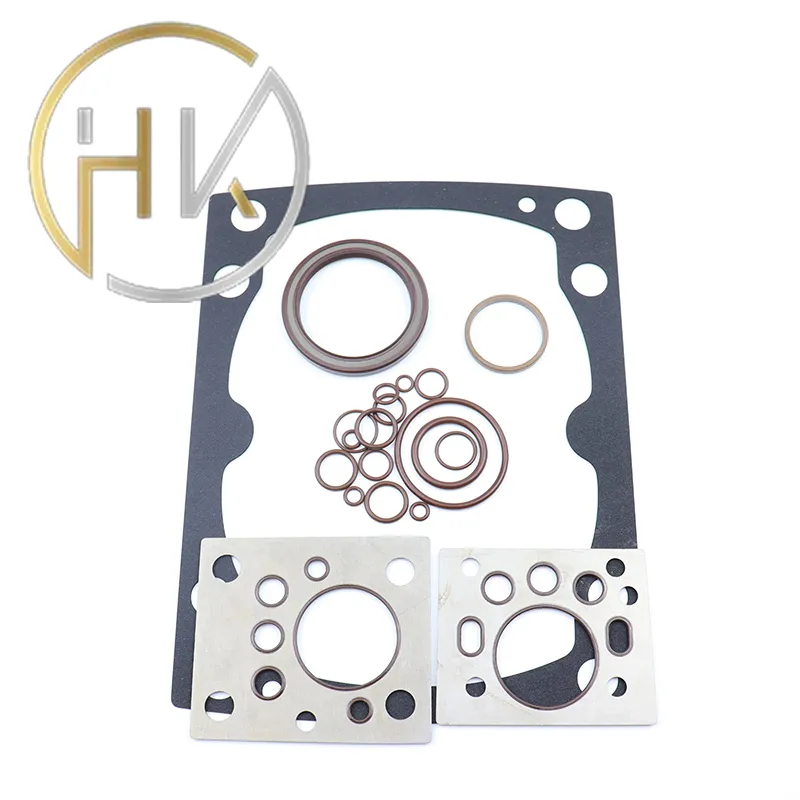

Key Components of Seal Kits

A typical hydraulic cylinder seal kit consists of several components, each with a specific function

1. Rod Seals These seals prevent hydraulic fluid from leaking out of the cylinder around the piston rod. They must endure high pressures and dynamic movements while resisting wear.

2. Piston Seals Located within the cylinder, piston seals keep the hydraulic fluid contained, allowing for proper movement and efficiency. They need to be robust enough to handle varying pressures and temperatures.

3. Guide Rings These components reduce friction between the moving parts of the hydraulic cylinder, ensuring smooth operation and minimal wear. They are critical for maintaining the alignment of the piston and rod.

5. O-rings O-rings are versatile components that serve various sealing purposes within the kit. They can be used on both static and dynamic seals to prevent fluid leakage.

hydraulic cylinder seal kits manufacturers

Factors to Consider When Choosing Manufacturers

When selecting a manufacturer for hydraulic cylinder seal kits, several factors must be taken into consideration

1. Quality of Materials The performance of seal kits largely depends on the materials used. Look for manufacturers who utilize premium elastomers and other materials resistant to temperature variations, pressure differences, and chemical exposure.

2. Customization Capabilities Different applications may require specific seal designs or dimensions. Manufacturers who offer customization options can provide unique solutions tailored to meet specific operational needs.

3. Certifications and Standards Ensure that the manufacturer complies with industry standards and certifications. This can be an indicator of reliability and quality assurance in their production processes.

4. Technical Expertise A knowledgeable manufacturer can offer valuable insights and recommendations about the best seal solutions for particular hydraulic applications. Consider their experience and technical support capabilities.

5. Testing Procedures A reputable manufacturer should conduct thorough testing of their seal kits to ensure they can withstand real-world conditions. Inquire about their quality control measures and testing methodologies.

Future Trends in Seal Kit Manufacturing

As technology advances, so too does the manufacturing of hydraulic cylinder seal kits. Innovations such as advanced materials, enhanced manufacturing techniques, and smart technology integrations are likely to shape the future of seal kits. Manufacturers who stay ahead of these trends will provide their clients with superior products that enhance efficiency and reliability in hydraulic systems.

Conclusion

Hydraulic cylinder seal kits are a vital component of efficient hydraulic systems. Understanding their importance and the various factors that influence their quality can help manufacturers make informed decisions when sourcing these essential products. By prioritizing quality, customization, and technological advancements, businesses can ensure that their hydraulic machinery operates optimally, minimizing downtime and enhancing overall productivity. Whether you are an OEM or a service provider, choosing the right seal kit manufacturer can make a significant difference in the effectiveness of your hydraulic applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories