Oct . 13, 2024 19:11 Back to list

hydraulic cylinder seal kits manufacturers

Understanding Hydraulic Cylinder Seal Kits Manufacturers

Hydraulic cylinders are pivotal components in numerous industrial applications, enabling the conversion of hydraulic energy into mechanical movement. The efficiency and longevity of these hydraulic systems heavily depend on the quality of their components, particularly the seals. This is where hydraulic cylinder seal kits come into play, manufactured by specialized companies dedicated to ensuring optimal performance and durability of hydraulic systems.

What are Hydraulic Cylinder Seal Kits?

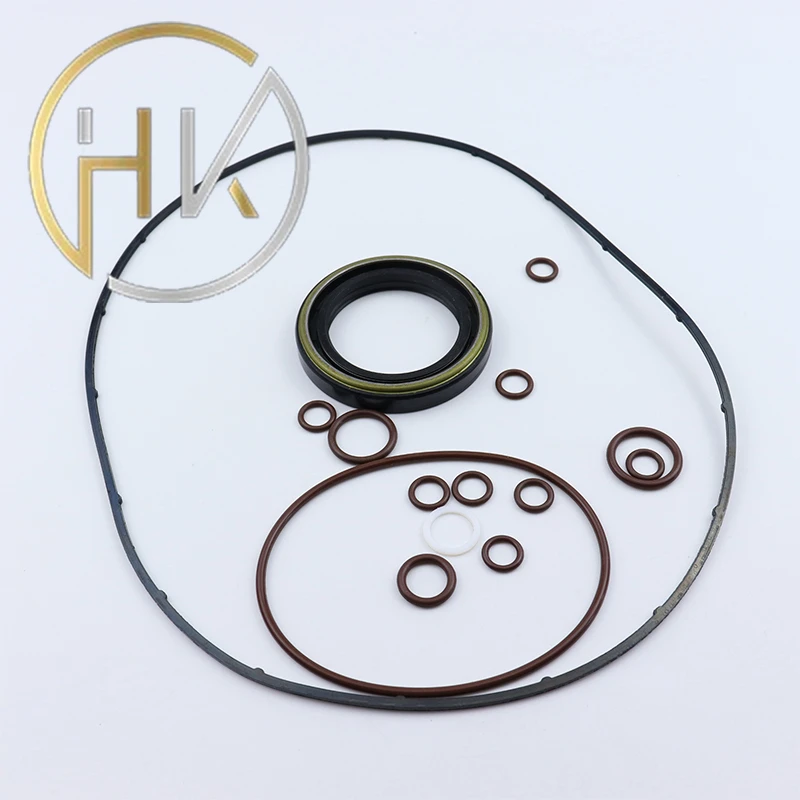

Hydraulic cylinder seal kits typically comprise various seals, O-rings, and other components that prevent fluid leaks, protect against contamination, and maintain pressure within the hydraulic system. The seals are crucial in ensuring that hydraulic fluid remains confined within the cylinder, allowing for effective operation. A well-designed seal kit not only enhances the performance of the hydraulic cylinders but also extends their lifespan.

Importance of Quality in Seal Kit Manufacturing

Manufacturers of hydraulic seal kits must adhere to high standards of quality to ensure their products meet industry requirements. The material used in the seals, such as rubber, polyurethane, or specialized compounds, plays a significant role in determining the performance of the seals. High-quality materials can withstand extreme temperatures, pressures, and the chemical properties of hydraulic fluids. Consequently, reputable manufacturers invest in research and development to create seals that meet or exceed these demands.

Moreover, precision engineering is essential. A slight discrepancy in dimensions can lead to improper sealing, resulting in leaks or failures. Therefore, manufacturers often employ advanced technologies and methodologies such as computer numerical control (CNC) machining to ensure that their products are crafted to exact specifications.

Leading Manufacturers in the Market

hydraulic cylinder seal kits manufacturers

Several companies have established themselves as leaders in the field of hydraulic cylinder seal kit manufacturing. They provide a vast selection of products designed for various applications, from construction and agriculture to automotive and aerospace industries. These manufacturers often offer customizable solutions, allowing customers to specify dimensions and materials tailored to their unique requirements.

Additionally, many leading manufacturers emphasize the importance of customer support and technical assistance. They work closely with clients to understand specific needs and provide recommendations based on industry best practices. This collaborative approach helps ensure that the right seal kits are selected, which can optimize performance and reduce downtime in operations.

Sustainability and Innovation

In recent years, there has been a growing emphasis on sustainability within the hydraulic seal manufacturing sector. Manufacturers are increasingly focusing on eco-friendly materials and production processes to minimize their environmental impact. This shift not only caters to the rising demand for sustainable solutions but also aligns with global efforts to reduce carbon footprints.

Innovation is another critical area where seal kit manufacturers are excelling. With advancements in material science and engineering, there is a continuous evolution in the designs and capabilities of hydraulic seals. This includes the development of seals that can withstand higher pressures and temperatures, improving efficiency and reliability in hydraulic systems.

Conclusion

In summary, hydraulic cylinder seal kits are essential components that significantly impact the performance and reliability of hydraulic systems. The role of manufacturers in producing high-quality, durable seal kits cannot be overstated. By prioritizing quality, precision engineering, customer collaboration, and sustainable practices, these manufacturers ensure that industries can rely on hydraulic systems for their demanding applications. As technology advances, the future of hydraulic seal manufacturing looks promising, with continual improvements expected in both materials and performance. This ultimately benefits not just the manufacturers, but also the countless industries that depend on hydraulic technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories