Sep . 25, 2024 18:29 Back to list

hydraulic cylinder seal kits by size

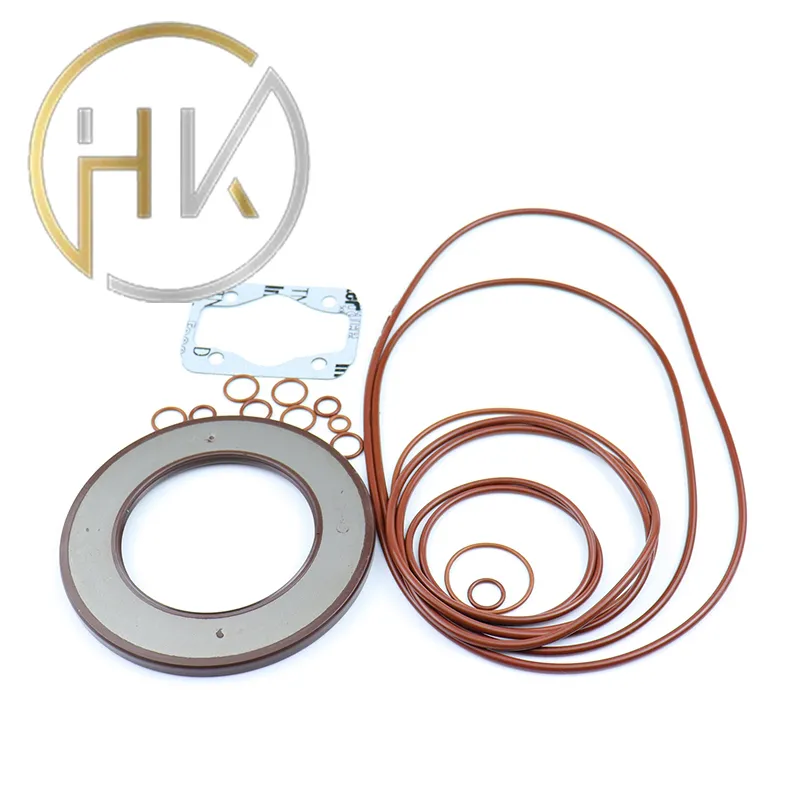

Understanding Hydraulic Cylinder Seal Kits by Size

Hydraulic systems play a vital role in various industries, powering machinery and equipment with the help of pressurized fluids. At the heart of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical force. To ensure the efficiency and longevity of these cylinders, proper sealing is essential. This leads us to the importance of hydraulic cylinder seal kits, particularly when categorized by size.

What are Hydraulic Cylinder Seal Kits?

Hydraulic cylinder seal kits are specially designed assemblies of seals, o-rings, and other components that are required to give a hydraulic cylinder the ability to function correctly. These kits serve multiple purposes they prevent the escape of hydraulic fluid, protect the internal components of the cylinder from contaminants, and help maintain pressure by keeping the hydraulic fluid contained within the system.

Importance of Sizing in Seal Kits

One of the most crucial aspects of hydraulic cylinder maintenance is ensuring that the correct seal size is used. Using the wrong size can lead to significant problems, including leaks, reduced efficiency, and even catastrophic failures. Seal size directly affects the performance of the hydraulic system. A seal that is too small may not provide a proper seal, leading to fluid leaks and potential system failure. Conversely, a seal that is too large can cause excessive friction, leading to increased wear and reduced operational efficiency.

Common Sizes of Hydraulic Cylinder Seals

Hydraulic seals come in various sizes, which are typically categorized by the diameter of the cylinder and the specific application requirements. Common sizes for hydraulic cylinder seals include standard sizes such as 2”, 3”, 4”, up to 6” and beyond, with both imperial and metric measurements available. It is essential for engineers and maintenance professionals to refer to the manufacturer’s specifications to determine the right size for their specific application.

How to Select the Right Seal Kit

When selecting hydraulic cylinder seal kits based on size, practitioners should consider the following factors

1. Cylinder Diameter Measure the bore diameter of the hydraulic cylinder accurately. This measurement will serve as the foundation for selecting the correct seal size.

2. Rod Size The diameter of the hydraulic rod must also be taken into account, as seals must fit snugly around both the rod and the bore to prevent leaks.

hydraulic cylinder seal kits by size

4. Application Type Different applications may require different types of seals. For example, a sealing solution for heavy-duty construction equipment might differ from that needed for lighter agricultural machinery.

5. Manufacturer Specifications Always check the manufacturer’s documentation for precise measurements and recommended seal sizes. This ensures compatibility and optimal performance.

Maintenance Tips

Regular maintenance of hydraulic cylinders is essential to extend their lifespan. Here are some maintenance tips related to seal kits

- Regular Inspection Frequently inspect seals for wear and tear. Early detection of issues can prevent costly repairs.

- Keep it Clean Contamination is a major cause of seal failure. Make sure to keep the area around the cylinder clean and free of debris.

- Fluid Quality Using high-quality hydraulic fluid can minimize wear on seals and enhance the overall performance of the hydraulic system.

- Installation Practices Proper installation is crucial. Ensure that seals are installed correctly to avoid damage during assembly.

Conclusion

Selecting the right hydraulic cylinder seal kits by size is vital for ensuring the efficient operation of hydraulic systems. By understanding the importance of size, selecting appropriate seals based on detailed measurements and conditions, and maintaining regular checks, you can ensure your hydraulic cylinders perform optimally. In a manufacturing environment, these practices safeguard against costly downtime and provide a reliable service life for critical hydraulic components. Consistency in the right seal choice accompanied by proper maintenance can make a significant difference in operational efficiency and long-term equipment reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories