Dec . 04, 2024 09:33 Back to list

hydraulic cylinder repair kits suppliers

The Importance of Hydraulic Cylinder Repair Kits A Guide for Suppliers

Hydraulic systems are essential in various industries, including construction, manufacturing, and agriculture. At the heart of these systems are hydraulic cylinders, which convert hydraulic energy into linear motion, enabling heavy machinery to perform vital tasks. However, like any mechanical component, hydraulic cylinders are subject to wear and tear, necessitating regular maintenance and, at times, repairs. This is where hydraulic cylinder repair kits come into play, making the role of suppliers pivotal in ensuring operational efficiency.

Understanding Hydraulic Cylinder Repair Kits

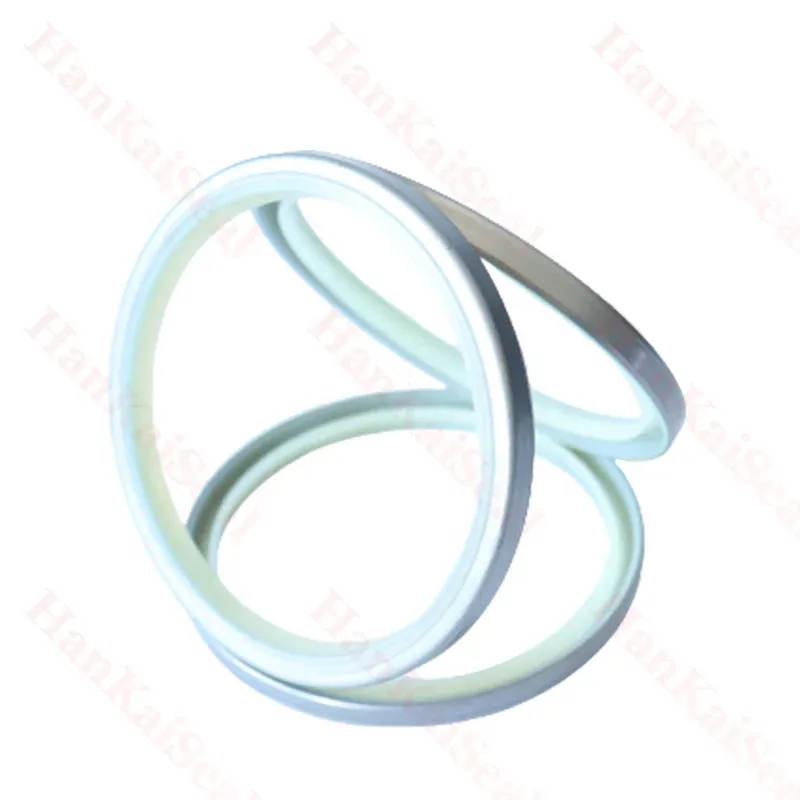

Hydraulic cylinder repair kits typically contain a variety of components necessary for the repair and maintenance of hydraulic cylinders. These components may include seals, O-rings, backup rings, wipers, and sometimes even replacement rods or barrels. The specific contents of a repair kit can vary depending on the size and type of the hydraulic cylinder, as well as the manufacturer's specifications.

The primary purpose of these kits is to help technicians perform repairs quickly and efficiently, minimizing downtime in industrial operations

. By using a comprehensive repair kit, workers can avoid the costs associated with replacing entire cylinders and instead focus on restoring the functionality of existing ones.The Role of Suppliers

For suppliers of hydraulic cylinder repair kits, understanding the intricacies of hydraulic systems and the specific needs of their clients is crucial. Suppliers must maintain an inventory of various kits to cater to diverse machinery and applications. Moreover, they should ensure that their kits meet industry standards and are compatible with high-performance hydraulic fluids.

hydraulic cylinder repair kits suppliers

One of the challenges suppliers face is the need for quality assurance. Given the critical nature of hydraulic systems in industrial settings, any failure in repair due to subpar components can lead to severe consequences, including machinery breakdown, safety hazards, and costly production losses. Therefore, suppliers should prioritize forming partnerships with reputable manufacturers who comply with stringent quality regulations.

Customer Education and Support

Aside from providing repair kits, suppliers play a vital role in educating their customers about the maintenance and repair processes. Offering technical support and guidance helps customers better understand how to use the kits effectively. This could involve workshops, instructional videos, or detailed product manuals. An informed client not only maximizes the efficiency of the repair process but also enhances the longevity of the hydraulic systems in question.

As hydraulic technology continues to evolve, suppliers must stay updated with the latest innovations in repair solutions. This may involve sourcing new materials for seals that can withstand harsher conditions or developing more comprehensive kits that cover a wider range of applications. Staying ahead of industry trends will position suppliers as leaders in the market and enhance their reputation among customers.

Conclusion

In conclusion, the role of hydraulic cylinder repair kits suppliers is vital in the lifecycle of hydraulic systems. By providing high-quality repair kits and knowledgeable support, suppliers contribute significantly to operational efficiency and safety. As industries continue to rely heavily on hydraulic systems, suppliers who prioritize quality, education, and innovation will not only enhance their own business prospects but also empower their clients to achieve superior performance in their operations. Investing in strong supplier relationships and a deep understanding of customer needs will ultimately drive success for both suppliers and their clients in the hydraulic repair industry.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories