Sep . 22, 2024 02:22 Back to list

hydraulic cylinder repair kits

Understanding Hydraulic Cylinder Repair Kits

Hydraulic cylinders are crucial components in many industrial applications, providing the power needed to lift, push, or move heavy loads. Over time, these cylinders can wear out or develop leaks due to continuous use, exposure to harsh environments, or lack of proper maintenance. When this happens, it’s essential to repair them promptly to avoid costly replacements and downtime. This is where hydraulic cylinder repair kits come into play.

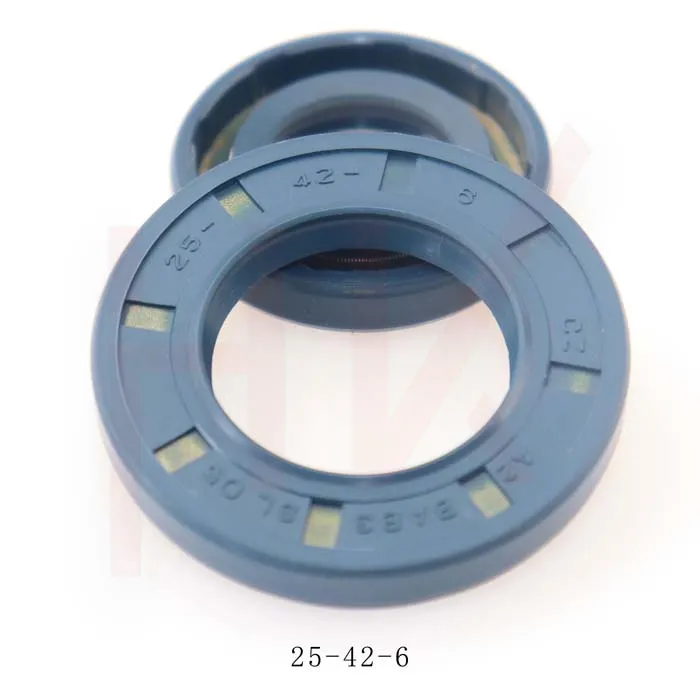

A hydraulic cylinder repair kit typically contains all the necessary components to restore a hydraulic cylinder to its original functionality. These kits usually include seals, O-rings, gaskets, and backup rings, which are essential for preventing leaks and ensuring smooth operation. Some kits might also include additional components, such as dust seals and installation tools, making them a comprehensive solution for repair.

When considering the use of a hydraulic cylinder repair kit, it’s crucial to select the right one for your specific cylinder model. Each hydraulic cylinder can vary in size, design, and specifications, so a precise fit is essential. Most manufacturers provide detailed information on the compatible parts in their repair kits, so it's advisable to consult the manufacturer’s guidelines or reach out to a knowledgeable supplier.

hydraulic cylinder repair kits

One of the primary benefits of using a repair kit instead of replacing the entire hydraulic cylinder is cost-effectiveness. Repairing a cylinder can significantly reduce maintenance expenses, especially for larger systems where replacement can incur substantial costs. Moreover, timely repairs can enhance the efficiency of operations, reducing the risk of equipment failure and unexpected downtime.

Preparation is key to a successful hydraulic cylinder repair. Before starting the repair process, it’s important to have the right tools on hand, including wrenches, a piston removal tool, and a clean workspace to ensure no contaminants enter the cylinder. An experienced technician should assess the cylinder for any additional damage beyond what is typically addressed by a repair kit. If the cylinder's barrel or rod shows significant wear or damage, it may require further attention or replacement.

In conclusion, hydraulic cylinder repair kits serve as an essential resource for maintaining the performance and longevity of hydraulic systems. By addressing leaks and wear issues promptly with these kits, businesses can save money, reduce downtime, and optimize operational efficiency. Regular maintenance and timely repairs of hydraulic cylinders not only prolong the lifespan of equipment but also enhance safety in environments where hydraulic systems are integral. As always, following proper repair procedures and manufacturer guidelines is vital for achieving the best results.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories