Dec . 03, 2024 18:42 Back to list

hydraulic cylinder repair kits

The Importance of Hydraulic Cylinder Repair Kits Ensuring Efficiency and Longevity

Hydraulic systems play a crucial role in a wide range of industries, including construction, manufacturing, and automotive. At the heart of these systems are hydraulic cylinders, which are responsible for converting hydraulic energy into mechanical force. Like any mechanical component, hydraulic cylinders can experience wear and tear over time, leading to leaks, reduced efficiency, and eventually failure. To address these issues, having access to hydraulic cylinder repair kits is essential for any operation that relies on hydraulic systems.

Understanding Hydraulic Cylinder Repair Kits

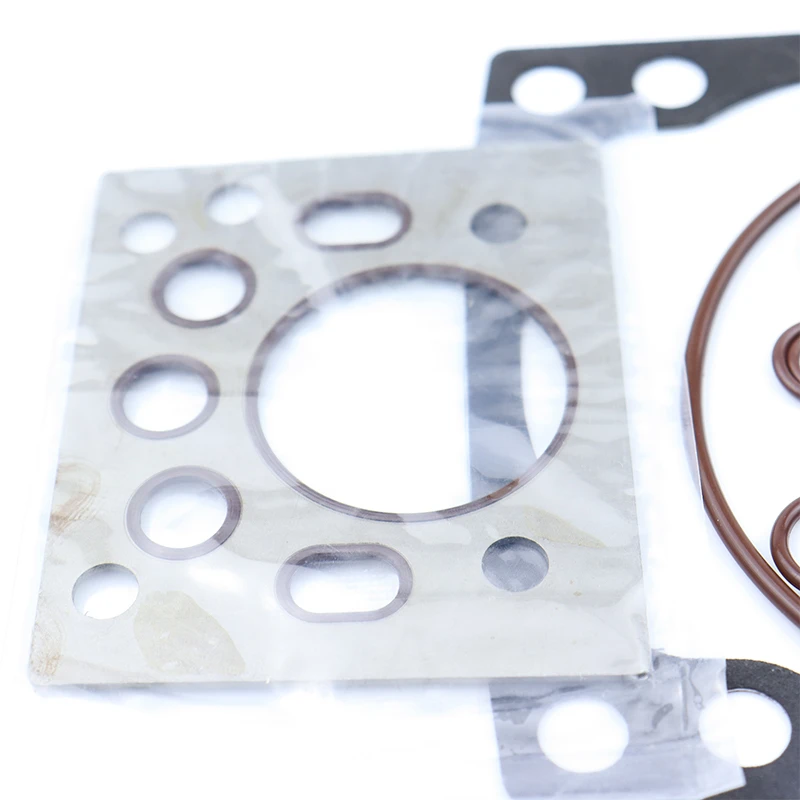

Hydraulic cylinder repair kits are designed to provide all the necessary components needed to restore a hydraulic cylinder to its optimal function. These kits typically include seals, O-rings, wipers, pistons, and other essential hardware that can degrade due to friction, temperature, and exposure to hydraulic fluids. The availability of a comprehensive repair kit means that companies can perform maintenance and repairs quickly, thus reducing downtime and improving productivity.

Key Components of Hydraulic Cylinder Repair Kits

1. Seals and O-Rings These components are crucial for preventing leaks in hydraulic systems. They create a tight seal between moving parts, ensuring that hydraulic fluid does not escape. High-quality seals can withstand pressure fluctuations and resist wear, which extends the lifespan of the hydraulic cylinder.

2. Wipers Wipers are vital for keeping contaminants out of the hydraulic cylinder. They remove dirt, debris, and other foreign particles that could cause damage to the internal components of the cylinder. Effective wipers are essential for maintaining the cleanliness and operational integrity of hydraulic systems.

3. Pistons Some repair kits include pistons that can be replaced when they show signs of wear. A well-functioning piston guarantees efficient movement within the cylinder, contributing to the overall performance of hydraulic systems.

4. Miscellaneous Hardware Many repair kits also come with additional hardware such as retaining rings, support rings, and backup rings, which are necessary for ensuring that the seals are held in place effectively.

Benefits of Using Repair Kits

1. Cost-Effectiveness Repairing a hydraulic cylinder using a repair kit is significantly more economical than replacing the entire cylinder. This can lead to substantial savings, especially for heavy machinery and equipment that can be expensive to replace.

hydraulic cylinder repair kits

2. Reduced Downtime Having a repair kit readily available allows for quick maintenance and repair. Reducing downtime is crucial in industries like construction where time is money. A minor repair might take only a few hours, allowing operations to resume promptly.

3. Increased Reliability Regular maintenance with the help of a repair kit leads to increased reliability of hydraulic systems. By addressing issues early, operators can prevent major breakdowns, ensuring that equipment remains operational and efficient.

4. Enhanced Performance A well-maintained hydraulic cylinder operates at maximum efficiency. With all components in good condition, the hydraulic system can achieve better performance, resulting in improved productivity.

Choosing the Right Repair Kit

When selecting a hydraulic cylinder repair kit, it is crucial to consider several factors

- Compatibility Ensure that the kit is compatible with the specific model of the hydraulic cylinder in use. Incorrect components can lead to further issues.

- Quality of Components Opt for kits that use high-quality materials designed to withstand the rigors of hydraulic operation. Cheaper alternatives may save money initially but can lead to more frequent failures.

- Manufacturer Recommendations Always check the manufacturer’s guidelines for maintenance and recommended parts. This ensures that any repairs or upgrades adhere to the original specifications.

Conclusion

Hydraulic cylinder repair kits are an indispensable tool for any organization that relies on hydraulic systems. By ensuring timely maintenance and repairs, businesses can significantly enhance the efficiency, reliability, and lifespan of their hydraulic equipment. Investing in high-quality repair kits not only saves money but also facilitates smoother and more productive operations. In the ever-evolving landscape of industrial machinery, being equipped with the right tools is essential for maintaining competitive advantage and operational excellence.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories