Nov . 10, 2024 21:30 Back to list

Hydraulic Cylinder Maintenance Solutions and Repair Kit Options for Efficient Performance

The Importance of Hydraulic Cylinder Repair Kits

Hydraulic systems are an integral part of many industrial machines, construction equipment, and automotive applications. They function by using pressurized fluid to perform work, allowing for powerful movements and actions in various settings. However, over time, hydraulic cylinders can wear out or malfunction due to numerous factors, such as contamination, fatigue, or improper maintenance. This is where hydraulic cylinder repair kits come into play, offering a practical solution for restoring functionality without the need for a complete cylinder replacement.

Understanding Hydraulic Cylinders

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy into linear motion. It consists of a cylinder barrel, a piston, and end caps, where hydraulic fluid enters and exits. The piston moves within the cylinder, producing motion that can lift, push, pull, or compress heavy loads. Typical applications include excavators, forklifts, and other machinery across various industries like manufacturing, construction, and agriculture.

Common Issues with Hydraulic Cylinders

Several issues can arise with hydraulic cylinders, leading to decreased performance or complete failure. Common problems include

1. Leaking Seals The seals within a hydraulic cylinder prevent fluid from escaping. Over time, these seals can wear out, leading to leaks that diminish system pressure and performance. 2. Cylinder Rod Damage The rod is constantly exposed to harsh conditions, including abrasion and corrosion. Damage to the rod can cause leaks and reduce the lifespan of the cylinder.

3. Piston Wear Continuous operation can lead to wear on the piston and cylinder walls, leading to inefficiencies and reduced power.

What Are Hydraulic Cylinder Repair Kits?

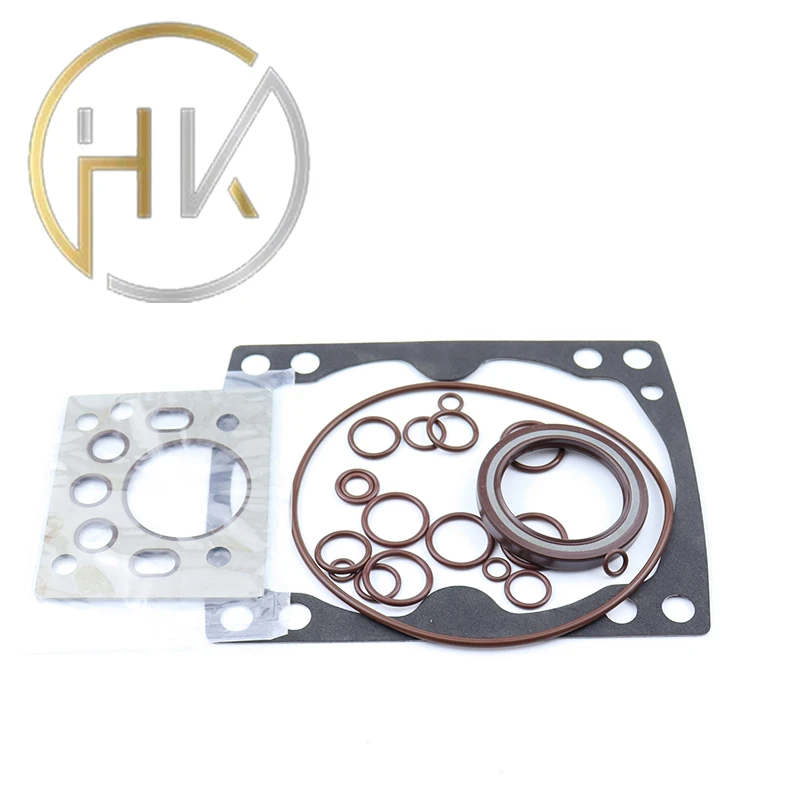

hydraulic cylinder repair kits

Hydraulic cylinder repair kits are specially designed packages containing all the necessary components to repair and maintain hydraulic cylinders. These kits often include

- Replacement Seals The key components needed to prevent leaks and ensure a tight fit. - Gaskets Essential for creating a seal between the cylinder components. - O-rings Used in various applications within the cylinder for sealing and preventing leaks. - Rod Wipers To keep contaminants from entering the cylinder, protecting internal components. - Piston Rings For ensuring proper sealing and efficient operation of the piston.

Benefits of Using Repair Kits

1. Cost-Effective Purchasing a repair kit is often significantly cheaper than replacing an entire hydraulic cylinder. This makes it an attractive option for businesses looking to reduce maintenance costs.

2. Convenience Repair kits come with all the necessary components for a complete repair, eliminating the hassle of sourcing individual parts.

3. Enhanced Lifespan Regular maintenance and timely repairs using these kits can extend the lifespan of hydraulic cylinders, enhancing the overall efficiency of the machinery.

4. Reduced Downtime With easy-to-follow instructions often included, repairs can be completed quickly, reducing downtime and increasing productivity.

5. Environmental Impact Repairing existing equipment rather than replacing it contributes to sustainability efforts by reducing waste and lowering the demand for new machinery production.

Conclusion

Hydraulic system maintenance is crucial for ensuring smooth operations in various applications. Hydraulic cylinder repair kits provide a practical, cost-effective solution for addressing common issues associated with hydraulic cylinders. By regularly maintaining and repairing these essential components, businesses can enhance the performance and lifespan of their machinery while minimizing downtime and environmental impact. Whether you are a seasoned technician or a DIY enthusiast, investing in hydraulic cylinder repair kits can lead to substantial long-term benefits. Don't wait until a malfunction occurs; equip yourself with the right tools to keep your hydraulic systems running smoothly.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories