Feb . 11, 2025 21:09 Back to list

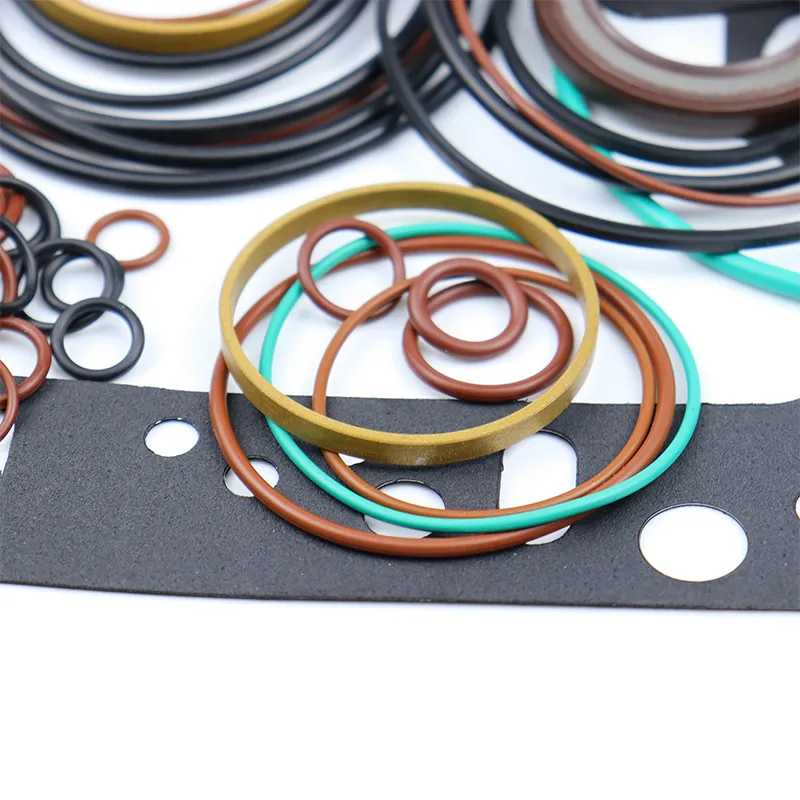

hydraulic cylinder rebuild kits

Learning from real-world experiences adds depth to the understanding of hydraulic cylinder maintenance. Seasoned professionals often share insights on forums or during training sessions, emphasizing best practices and the subtleties of successful cylinder rebuilding. For instance, the importance of adequately lubricating seals before installation to prevent premature wear is a tip frequently highlighted by experienced technicians. They also stress the necessity of maintaining a meticulously clean environment during assembly, as contaminants can compromise the integrity of seals and other components. In applications where hydraulic systems are subjected to extreme conditions, such as intense heat or pressure, selecting a rebuild kit developed specifically for those environments enhances trustworthiness. These specialized kits may incorporate advanced materials, such as Viton or Teflon seals, which offer superior performance under harsh conditions. Employing such tailored solutions underscores a commitment to not only meeting but exceeding operational requirements. Ultimately, the trustworthiness of hydraulic cylinder rebuild kits is a pivotal factor in maintaining system resiliency. Quality kits serve as a preventive measure, ensuring that machinery operates smoothly and efficiently. Investing in reliable components from authoritative suppliers is not just a cost-effective strategy but also a testament to an organization's dedication to excellence in maintenance practices. In conclusion, the role of hydraulic cylinder rebuild kits extends beyond mere component replacement. They encapsulate a blend of experience, expertise, and authority, fostering trust in their ability to uphold and enhance the performance of hydraulic systems. By integrating quality rebuild kits into maintenance routines, organizations can significantly reduce operational disruptions and uphold the integrity of their machinery, leading to enhanced productivity and sustained operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories