Nov . 22, 2024 04:19 Back to list

hydraulic cylinder rebuild kits

Understanding Hydraulic Cylinder Rebuild Kits

Hydraulic cylinders are critical components in various machinery, including construction equipment, manufacturing machinery, and even automobiles. Over time, these cylinders may experience wear and tear due to prolonged use, which can lead to reduced efficiency or even failure. To ensure that hydraulic systems continue to operate smoothly, many operators turn to hydraulic cylinder rebuild kits.

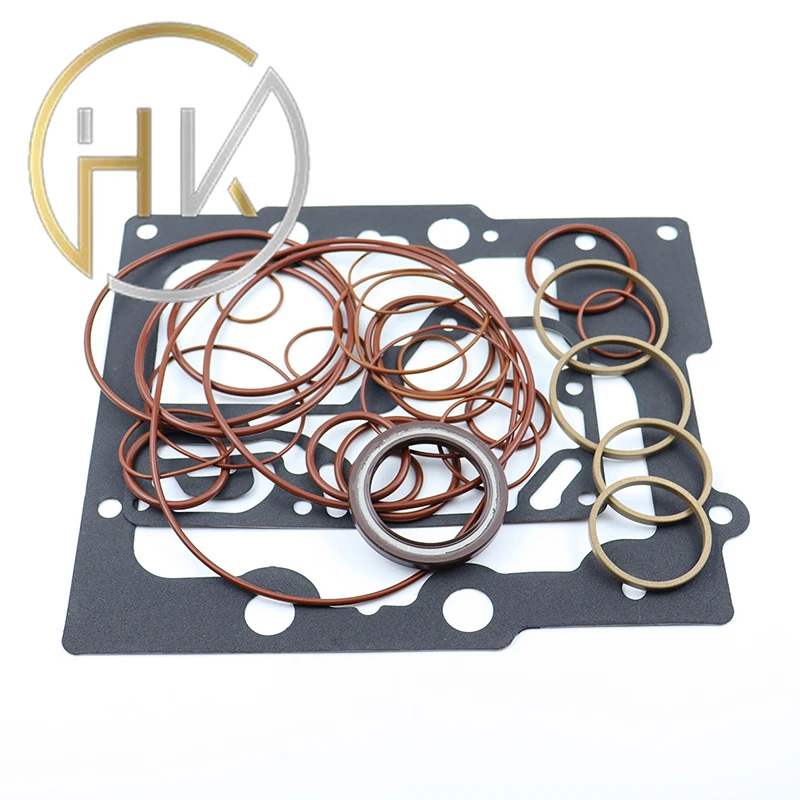

A hydraulic cylinder rebuild kit is a comprehensive package that includes all the necessary components needed to refurbish and restore the functionality of a hydraulic cylinder. These kits typically contain items such as seals, O-rings, pistons, gaskets, and retaining rings, all essential for maintaining the integrity and performance of the hydraulic system. Choosing the correct kit for your specific hydraulic cylinder is crucial, as each cylinder may require different components based on its design and operational demands.

One major advantage of using hydraulic cylinder rebuild kits is the cost-effectiveness they offer. Instead of purchasing a completely new hydraulic cylinder, which can be quite expensive, operators can save money by simply replacing the worn-out parts. This not only reduces operational costs but also contributes to sustainability by minimizing waste and the need for new materials.

hydraulic cylinder rebuild kits

Furthermore, rebuilding your hydraulic cylinder can lead to enhanced performance. Over time, seals can degrade, leading to leaks and inefficiencies in the hydraulic system. By using a rebuild kit, you can replace these seals, resulting in improved pressure retention and better overall performance of the hydraulic system. This can ultimately extend the lifespan of the machinery involved and improve productivity.

When considering a hydraulic cylinder rebuild kit, it’s important to ensure that you’re sourcing your components from reputable manufacturers. High-quality materials are essential for the performance and durability of the seals and other components. Inferior materials can lead to premature failure, negating the benefits of rebuilding in the first place.

In addition to performance and cost considerations, operators should also take the time to read the instructions provided with the rebuild kit carefully. Hydraulic systems can be complex, and proper installation is key to achieving optimal results. If necessary, consulting with a professional or mechanic who specializes in hydraulic systems can help ensure that the rebuild is successful.

In conclusion, hydraulic cylinder rebuild kits provide a practical solution for maintaining the performance and longevity of hydraulic systems. By understanding the components included in these kits and their importance, machinery operators can make informed decisions that save costs and enhance operational efficiency. Embracing regular maintenance and timely rebuilds not only supports equipment reliability but also contributes to the overall productivity of operations across various industries.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories