Dec . 11, 2024 12:08 Back to list

hydraulic cylinder packing kits

Understanding Hydraulic Cylinder Packing Kits Essential Components for Optimal Performance

Hydraulic systems are integral to the operation of various machinery, ranging from construction equipment to industrial machinery. At the heart of these systems lies the hydraulic cylinder, which is responsible for converting hydraulic energy into linear motion. A crucial component of hydraulic cylinders is their packing kits, which ensure that the hydraulic fluid remains contained and pressurized, thereby enabling optimal performance.

What are Hydraulic Cylinder Packing Kits?

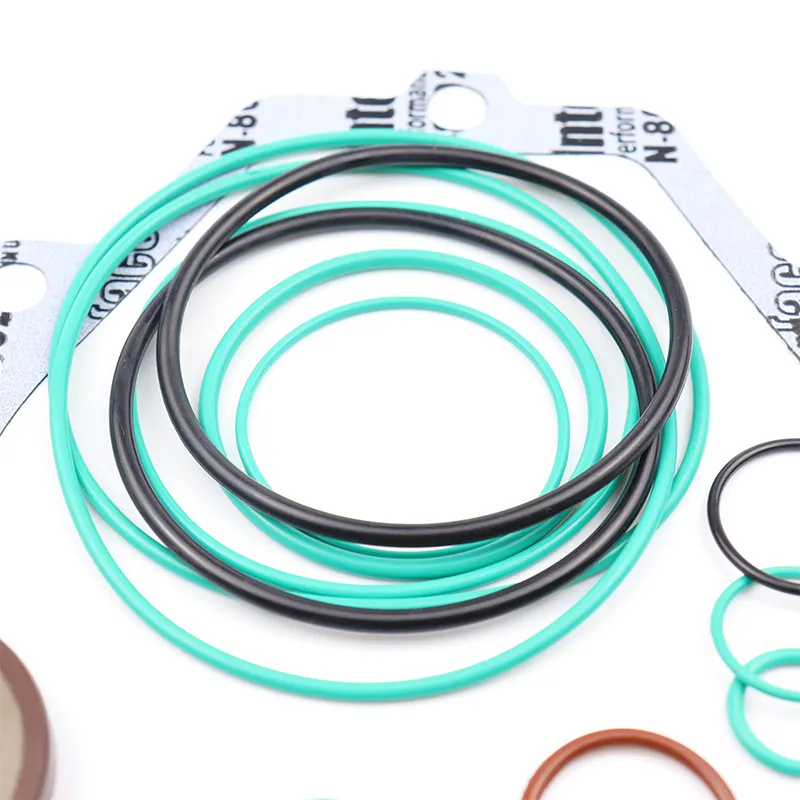

Hydraulic cylinder packing kits consist of a collection of seals, O-rings, and other components designed to prevent fluid leaks and maintain pressure within the cylinder. These kits are engineered to withstand the harsh conditions typical in hydraulic systems, including high pressure, temperature fluctuations, and exposure to various chemicals. A well-functioning packing kit not only prevents leaks but also supports the efficient operation of the hydraulic cylinder, leading to improved performance and reduced downtime.

Types of Packing Kits

Packing kits come in various configurations, tailored to match specific hydraulic cylinder designs and applications. Some of the most common types include

1. Rod Packing Kits These kits are installed around the piston rod and are designed to prevent fluid from leaking out when the rod is extending or retracting. They generally include dynamic seals, static seals, and wear rings.

2. Piston Packing Kits Found inside the cylinder, these kits are responsible for sealing the piston against the cylinder wall to maintain pressure. They can include lip seals, U-cups, and backup rings.

3. End Cap Packing Also known as end seals, these are used to close the ends of the hydraulic cylinder, preventing leakage while accommodating the linear movement of the rod.

Material Considerations

hydraulic cylinder packing kits

The materials used in hydraulic cylinder packing kits are crucial for their performance and longevity. Commonly utilized materials include

- Nitrile Rubber (NBR) Highly resistant to oil and various chemicals, NBR is the most widely used material for hydraulic seals due to its durability in a wide range of temperatures.

- Polyurethane Known for its excellent abrasion resistance and elasticity, polyurethane is used in applications where the seal will experience substantial wear.

- PTFE (Teflon) PTFE seals exhibit low friction properties, making them ideal for high-speed applications. They are resistant to a broad range of chemicals and temperatures.

Choosing the right material for a packing kit largely depends on the specific application, including the type of hydraulic fluid used, operating temperature, and pressure levels.

Importance of Regular Maintenance

Regular maintenance of hydraulic cylinder packing kits is essential for ensuring the longevity and efficiency of hydraulic systems. Signs of wear, such as fluid leaks or decreased performance, indicate that it's time to inspect and possibly replace the packing kits. Failure to address these issues can lead to more severe problems, such as complete cylinder failure, costly repairs, and prolonged downtime.

Conclusion

Hydraulic cylinder packing kits play a pivotal role in the performance and reliability of hydraulic systems. Understanding their components, materials, and proper maintenance can help operators ensure optimal operation, extend the life of their equipment, and minimize the risk of unexpected failures. Whether you are involved in construction, manufacturing, or any industry relying on hydraulic systems, investing in high-quality packing kits and maintaining them regularly will contribute significantly to operational efficiency and safety.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories