Dec . 21, 2024 00:18 Back to list

hydraulic cylinder oil seal

Understanding Hydraulic Cylinder Oil Seals Their Importance and Functionality

Hydraulic cylinders are crucial components in various machinery and equipment, utilized widely in construction, manufacturing, and automotive industries. At the core of a hydraulic system's efficiency lies the oil seal, an integral part that ensures the integrity of the hydraulic system. Oil seals are designed to retain oil, prevent contamination, and maintain the necessary pressure within the hydraulic cylinder. Their role is instrumental in ensuring that hydraulic machinery operates smoothly and effectively.

The Function of an Oil Seal

An oil seal acts as a barrier in hydraulic cylinders, preventing hydraulic fluid from leaking out while simultaneously keeping dirt, debris, and moisture from entering the cylinder. The hydraulic systems typically operate under high pressure, and any leakage can lead to reduced efficiency, increased wear and tear, or complete hydraulic failure. By creating a proficient seal, the oil seal preserves the lubrication of moving parts, which is essential to the cylinder's operation and longevity.

Types of Hydraulic Cylinder Oil Seals

There are several types of oil seals used in hydraulic cylinders, each designed to meet specific needs based on the operating conditions

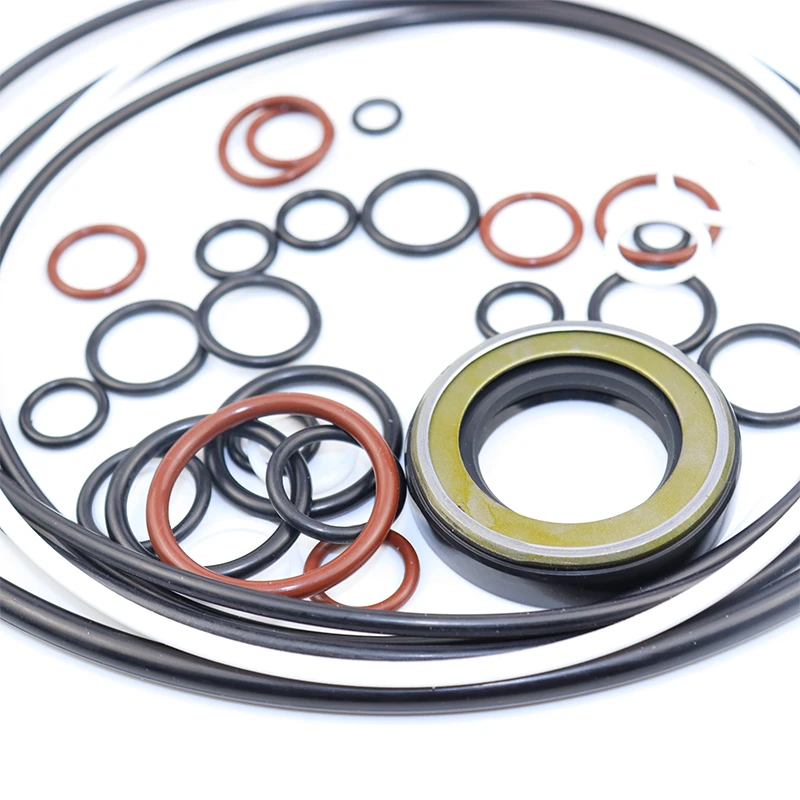

1. Lip Seals These are the most common type of oil seals found in hydraulic applications. They consist of a flexible lip that slides against the shaft, creating a seal that is effective in retaining oil while preventing contaminants from entering.

2. U-Cups U-cup seals are designed to handle dynamic pressure and provide excellent sealing capabilities. Their unique shape allows them to adapt to variations in pressure, making them suitable for both low and high-pressure hydraulic systems.

3. Backup Rings Often used in conjunction with other seals, backup rings prevent seal extrusion under high pressure. They provide support, maintaining the integrity of the primary seal and extending its life.

hydraulic cylinder oil seal

4. O-Rings Commonly used in static sealing applications, O-rings can also be found in dynamic applications. They are versatile and can be manufactured from various materials to suit different fluids and temperatures.

Material Selection

The material used to manufacture hydraulic cylinder oil seals is crucial for their performance. Common materials include elastomers like nitrile, polyacrylate, and viton, all of which offer different properties suited for various environments. For instance, nitrile rubber is widely used due to its excellent resistance to petroleum products, while viton offers superior thermal stability and chemical resistance, making it ideal for high-temperature applications.

Installation and Maintenance

Proper installation of hydraulic cylinder oil seals is critical to their performance. A poorly installed seal can lead to premature failure, resulting in costly repairs and downtime. It is essential to follow the manufacturer’s guidelines for installation, ensuring that the seal is correctly positioned and free from debris.

Regular inspections and maintenance of hydraulic systems will also prolong the lifespan of oil seals. Look for signs of wear, such as leaks or visible damage, and replace seals as necessary. Additionally, keeping the hydraulic fluid clean and free of contaminants will help maintain the integrity of the seals and the entire hydraulic system.

Conclusion

Hydraulic cylinder oil seals play a vital role in the functionality and reliability of hydraulic systems. Understanding their types, materials, and maintenance can help operators and engineers ensure the longevity and efficiency of the equipment. Whether in construction machinery, industrial equipment, or vehicles, the integrity of an oil seal directly impacts the operation of the hydraulic system. Therefore, investing time and resources in proper selection, installation, and maintenance of these seals is paramount for optimal performance and minimized operational costs. In the ever-evolving landscape of technology and engineering, the humble oil seal continues to be a cornerstone of hydraulic system efficiency and reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories