Nov . 17, 2024 10:12 Back to list

hydraulic cylinder oil seal

Understanding Hydraulic Cylinder Oil Seals

Hydraulic systems are an integral part of modern machinery across various industries, from construction and manufacturing to automotive applications. At the heart of these systems are hydraulic cylinders, which convert fluid power into mechanical energy. However, efficient operation of hydraulic cylinders relies heavily on one critical component the oil seal.

What Are Hydraulic Cylinder Oil Seals?

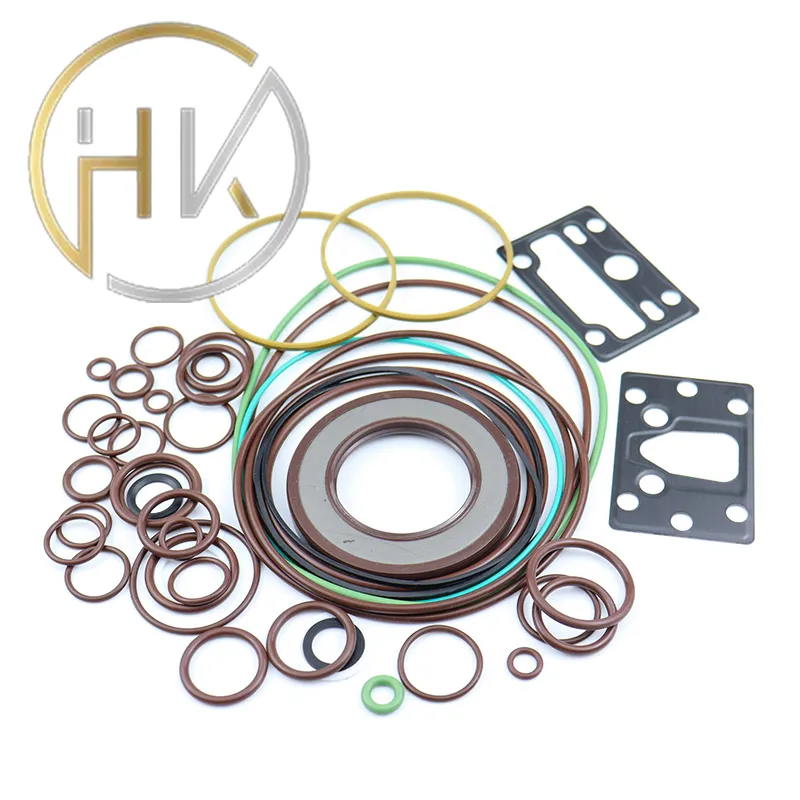

Hydraulic cylinder oil seals are specialized seals used to retain hydraulic fluid within the cylinder while preventing external contaminants from entering. They play a vital role in maintaining the efficiency and longevity of hydraulic systems. An oil seal's primary functions include preventing leaks, reducing friction between moving parts, and ensuring the smooth operation of hydraulic cylinders.

Types of Oil Seals

Oil seals come in various designs and materials, each suited for different applications. The most common types include

1. Rubber Seals Made from synthetic or natural rubber, these seals provide excellent compression and resilience, making them suitable for a wide range of temperatures and pressures.

2. Polyurethane Seals Known for their superior abrasion resistance, polyurethane seals are ideal for applications where wear and tear are a concern.

3. Metal Cased Seals These seals combine metal reinforcement with rubber components, providing added durability while maintaining a secure sealing capability.

4. Composite Seals Utilizing a blend of materials, composite seals offer enhanced performance characteristics and the ability to withstand harsh environments.

Factors Influencing Seal Selection

When selecting an oil seal for hydraulic cylinders, several factors must be considered

hydraulic cylinder oil seal

- Operating Pressure and Temperature Different seals can withstand varying pressure and temperature ranges. It's crucial to choose a seal that meets the specific conditions of your hydraulic system.

- Fluid Compatibility The seal material must be compatible with the hydraulic fluid being used, whether it is mineral oil, water-based fluid, or some other type

. Incompatibility can lead to deterioration of the seal and ultimately, system failure.- Speed of Operation High-speed applications may require seals designed specifically to handle increased friction and heat generation.

- Contaminant Exposure In environments where contaminants are prevalent, selecting seals with superior dirt-exclusion capabilities is essential to prolong the seal's lifespan.

Maintenance and Troubleshooting

Preventing seal failure is critical to ensuring the longevity and efficiency of hydraulic systems. Regular maintenance checks can help identify potential issues early. Some common signs of oil seal failure include

- Fluid Leaks The most apparent indicator of seal failure, often accompanied by decreased system pressure.

- Increased Friction or Noise Unusual sounds or increased resistance during operation can suggest that seals are wearing or damaged.

- Contamination in the Hydraulic Fluid If the hydraulic fluid shows signs of contamination, it may indicate that the oil seal is allowing dirt or foreign objects to enter the system.

To troubleshoot and fix seal-related issues, it is important to inspect the seals regularly and replace them as necessary. When changing oil seals, always adhere to the manufacturer’s specifications to ensure the proper fit and function.

Conclusion

Hydraulic cylinder oil seals may seem like a minor component in the grand scheme of hydraulic systems, but their role is undeniably critical. By understanding the types, functions, and maintenance needs of these seals, operators can significantly improve the reliability and efficiency of their hydraulic machinery. Investing in high-quality seals and adhering to proper maintenance practices will ensure optimal performance and longevity of hydraulic systems. Effective use of hydraulic oil seals is essential for minimizing downtime and maximizing productivity in any hydraulic application.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories