Nov . 27, 2024 17:47 Back to list

Hydraulic Cylinder Repair Kits for Efficient and Reliable Maintenance Solutions

Repairing Hydraulic Cylinder Kits A Comprehensive Guide

Hydraulic cylinders are vital components in various mechanical systems, providing the force needed for lifting, pressing, and moving objects. Over time, these cylinders may require repairs and maintenance, especially if they have been subjected to heavy use or harsh environmental conditions. One of the most effective ways to ensure the longevity and efficient performance of hydraulic cylinders is to utilize hydraulic cylinder repair kits. This article discusses the importance of repairing hydraulic cylinders, the components of repair kits, and steps for effective repairs.

Importance of Repairing Hydraulic Cylinders

The functionality of hydraulic machinery heavily relies on hydraulic cylinders. When a hydraulic cylinder fails, it can lead to significant downtime in operations, resulting in increased costs for businesses. Regular maintenance and timely repairs can prevent complete breakdowns and extend the lifespan of hydraulic equipment. Furthermore, repairing hydraulic cylinders can often be more cost-effective than replacing them entirely, making it an appealing option for many operators.

Components of Hydraulic Cylinder Repair Kits

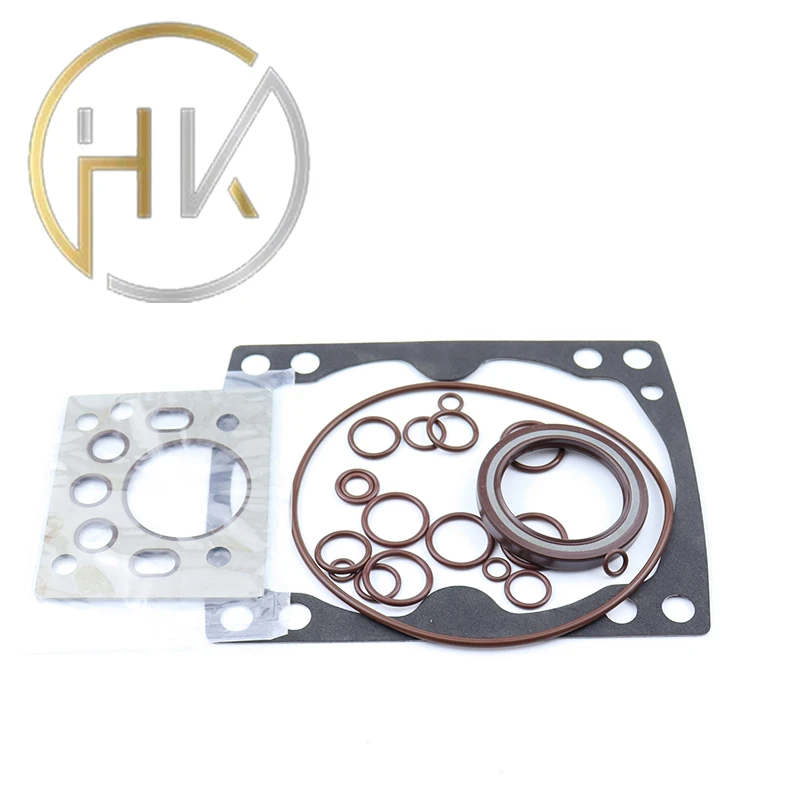

Hydraulic cylinder repair kits typically include various components necessary for restoring the functionality of the cylinder. These kits may differ based on the type of cylinder and manufacturer, but they generally contain

1. O-Rings and Seals These are critical for preventing hydraulic fluid leaks, which can significantly affect the performance of the cylinder. 2. Rod Wipers Rod wipers help keep contaminants from entering the cylinder, protecting the internal components from wear and tear.

3. Gaskets Gaskets provide sealing between different components of the hydraulic system, ensuring efficient operation.

4. Piston Seals Piston seals are essential for maintaining pressure within the cylinder, directly impacting its performance.

5. Tools and Instruction Manuals Many repair kits come with specialized tools required for the installation of the components, as well as detailed instructions to guide users through the repair process.

Steps for Effective Repairs

hydraulic cylinder kits repair

Repairing hydraulic cylinders requires a systematic approach to ensure that all components are correctly addressed. Here are some steps to follow

1. Safety First Always ensure that the hydraulic system is depressurized before beginning any work. Wear appropriate personal protective equipment (PPE).

2. Disassemble the Cylinder Carefully detach the hydraulic cylinder from its mounting. Take photographs or make notes of the assembly for reference during reassembly.

3. Inspect Components Assess the condition of the cylinder, rods, seals, and other components for wear or damage. This assessment will help determine which parts need replacement.

4. Clean and Prepare Thoroughly clean all components using appropriate solvents to remove dirt, grime, and old fluid. Ensure that all surfaces are free of contaminants before reassembly.

5. Install New Components Follow the instructions provided in the repair kit to install the new seals, O-rings, and any other parts. Make sure to lubricate seals before installation to prevent damage during assembly.

6. Reassemble the Cylinder Carefully reassemble the hydraulic cylinder, ensuring all components are correctly aligned and seated. Follow your notes or photographs to maintain the original configuration.

7. Test the Cylinder Once the cylinder has been reassembled, it should be tested under low pressure briefly to check for any leaks or performance issues. If all seems well, gradually bring the system up to normal operating pressure while monitoring for problems.

8. Regular Maintenance Once repaired, ensure regular maintenance checks on the hydraulic cylinder to prevent future issues. This includes routine inspections and cleaning.

Conclusion

Hydraulic cylinder repair kits are invaluable tools for maintaining the performance and efficiency of hydraulic systems. By utilizing these kits and following systematic repair procedures, operators can significantly extend the lifespan of their hydraulic cylinders while minimizing downtime and repair costs. Proper training and safety precautions should always be a priority when performing repairs to safeguard against injury and equipment damage. With a little effort and care, hydraulic cylinders can continue to provide reliable service for many years to come.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories