Nov . 12, 2024 21:10 Back to list

hydraulic cylinder kits repair

A Comprehensive Guide to Hydraulic Cylinder Kits Repair

Hydraulic systems are vital in various industries, providing powerful and efficient means of transferring energy through fluid. Among the most critical components in these systems are the hydraulic cylinders. Over time, these cylinders may wear out or develop leaks, necessitating repair or replacement. Understanding how to repair hydraulic cylinder kits is essential for maintaining system efficiency and preventing costly downtime.

Understanding Hydraulic Cylinders

Hydraulic cylinders convert hydraulic energy into mechanical energy, allowing machines to perform tasks such as lifting, pushing, or pulling. They consist of several key components the cylinder barrel, piston, piston rod, seals, and end caps. Each of these parts plays a crucial role in ensuring the cylinder operates smoothly. However, due to constant movement and exposure to extreme pressures and environments, hydraulic cylinders are susceptible to wear and tear.

When to Repair Hydraulic Cylinders

Recognizing the signs of trouble in a hydraulic cylinder is the first step toward effective repair. Common indicators include

1. Leakage Visible fluid leaking from the cylinder is a clear sign of wear on seals or cylinder components. 2. Reduced Performance If the hydraulic system is not performing as efficiently as before, it may be time to inspect the cylinders. 3. Uneven Movement Jerky or inconsistent movement can indicate internal issues, possibly requiring immediate attention. 4. Visible Damage Rust, corrosion, or pitting on the cylinder surface can compromise its integrity.

Choosing a Hydraulic Cylinder Repair Kit

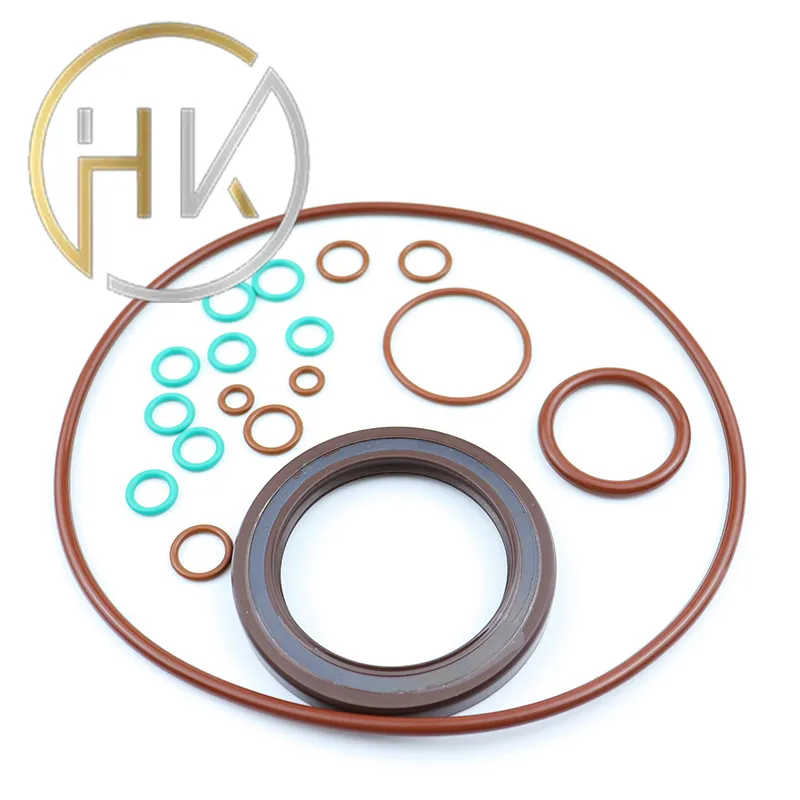

Once you identify a need for repair, the next step is to choose a hydraulic cylinder repair kit. These kits typically include all the necessary components for overhauling a cylinder, such as seals, O-rings, bearing kits, and sometimes even new pistons. When selecting a repair kit, consider the following factors

- Compatibility Ensure that the kit is compatible with your specific cylinder model and manufacturer. - Quality of Materials Look for kits made from high-quality materials that can withstand the pressures and conditions in which your hydraulic system operates. - Comprehensive Contents A good repair kit should contain all the components you need for a complete overhaul, reducing the need for additional purchases.

Steps for Repairing Hydraulic Cylinder Kits

Here’s a step-by-step guide on repairing hydraulic cylinder kits

hydraulic cylinder kits repair

1. Preparation Begin by ensuring that you have all the tools and parts needed for the repair. Common tools include wrenches, screwdrivers, and a cylinder hone.

2. Disassembly Carefully disassemble the hydraulic cylinder. Start by removing the cylinder head and piston rod. Pay close attention to the arrangement of parts as you take them apart for easier reassembly.

3. Inspection Examine each component for signs of wear or damage. Look for scratches, dents, or excessive wear on the seals and bearing surfaces. Replace any parts that are beyond repair.

4. Cleaning Thoroughly clean the cylinder barrel and all components. Use a suitable degreaser and avoid abrasive materials that could damage the surfaces.

5. Reassembly Begin reassembling the cylinder using the new components from your repair kit. Apply grease to the O-rings and seals and install them carefully to avoid pinching or damaging them.

6. Testing Once reassembled, test the hydraulic cylinder under its normal operating conditions. Monitor for any leaks or irregular movements, ensuring that the repair was successful.

Preventative Maintenance Tips

To extend the lifespan of your hydraulic cylinders and minimize the need for repairs, consider these preventative maintenance tips

- Regular Inspections Periodically inspect your hydraulic cylinders for signs of wear or damage. - Maintain Cleanliness Keep the hydraulic system clean, as dirt and debris can lead to premature wear. - Monitor Fluid Levels Ensure that the hydraulic fluid is at the appropriate levels and replace it as needed.

Conclusion

Repairing hydraulic cylinder kits is an essential skill for anyone working with hydraulic systems. By understanding when and how to perform repairs, selecting the right kits, and following proper maintenance practices, you can keep your hydraulic cylinders functioning smoothly and efficiently, ultimately saving time and money while boosting productivity. Regular attention to hydraulic cylinder health is an investment in the longevity of your machinery and operational success.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories