Nov . 25, 2024 06:50 Back to list

hydraulic breaker seal kit

Understanding Hydraulic Breaker Seal Kits An Essential Component for Performance and Longevity

Hydraulic breakers are powerful tools widely used in construction and demolition to break up concrete, rock, and other hard materials. These robust machines rely heavily on hydraulic systems, and the efficiency of these systems is significantly influenced by the quality of components, particularly the seal kits. This article will discuss the importance of hydraulic breaker seal kits, their components, maintenance, and how they contribute to the overall performance and longevity of hydraulic breakers.

What is a Hydraulic Breaker Seal Kit?

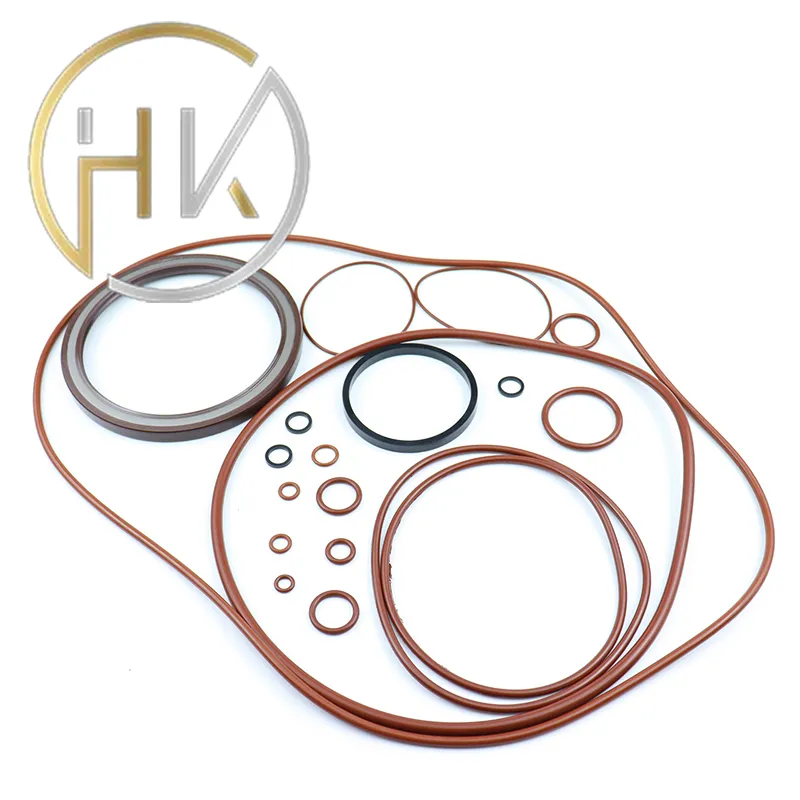

A hydraulic breaker seal kit is a collection of seals and O-rings that are designed to prevent hydraulic fluid leaks within the hydraulic breaker. These components play a crucial role in maintaining the pressure required for the efficient operation of the breaker. A well-functioning seal kit ensures that the hydraulic system remains sealed, minimizing the risk of failure and maximizing the tool's efficiency.

Components of a Seal Kit

Typically, a hydraulic breaker seal kit includes various seals and O-rings made from materials specifically designed to handle hydraulic fluids and withstand high pressure and temperature variations. Common components include

1. O-Rings These ring-shaped seals prevent fluid from leaking between moving parts. They are critical for creating a tight seal in cylindrical spaces. 2. Rod Seals These seals are used to prevent fluid leakage along the rod of the hydraulic breaker, ensuring the hydraulic system maintains pressure and operates effectively.

3. Piston Seals Positioned within the cylinder, these seals allow for the smooth movement of the piston while preventing fluid from escaping.

4. Backup Rings These rings provide additional support to O-rings, preventing them from extruding under high pressure.

5. Wiper Seals These seals help keep contaminants like dirt and debris out of the hydraulic system, which is vital for protecting the internal components from damage.

Importance of Seal Kits

The integrity of the hydraulic system wholly depends on the quality and condition of the seal kits

. Here are a few reasons why maintaining proper seal kits is essentialhydraulic breaker seal kit

1. Preventing Hydraulic Leaks Leaks can lead to a reduction in pressure, causing the hydraulic breaker to perform poorly or fail entirely. Regularly replacing worn seals can prevent these costly leaks.

2. Extending Equipment Life Hydraulic components are subjected to extreme conditions and wear. A functional seal kit reduces wear and tear on critical parts, ultimately extending the equipment's lifespan.

3. Enhancing Performance With a properly sealed hydraulic system, the breaker can operate at peak efficiency, providing consistent power and performance.

4. Reducing Downtime Regular inspections and timely replacements of seal kits can prevent unexpected breakdowns and project delays.

Maintenance Tips

To ensure that your hydraulic breaker and its seal kit remain in optimal condition, consider the following maintenance tips

- Regular Inspections Frequently check for any signs of wear or damage to the seals. Look for leaks or fluid accumulation around the hydraulic components.

- Environment Control Try to keep the hydraulic breakers away from harsh conditions, such as extreme temperatures and contaminants, which can accelerate wear.

- Quality Replacement Parts Always opt for high-quality OEM (Original Equipment Manufacturer) seal kits when replacing old seals. Substandard parts can lead to premature failures.

- Follow Manufacturer Guidelines Adhere to the maintenance schedule recommended by the manufacturer for inspections and part replacements.

Conclusion

In conclusion, hydraulic breaker seal kits are crucial for the efficient operation and longevity of hydraulic breakers. By ensuring the integrity of the hydraulic system, these seal kits prevent leaks, enhance performance, and reduce downtime. Regular maintenance and the use of quality components will contribute significantly to the productivity and reliability of hydraulic breaker equipment, making it a vital aspect of any construction or demolition project.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories