Sep . 07, 2024 15:23 Back to list

Hydraulic Seal Repair Kit - Restore Your Equipment Efficiency

Understanding Hydraulic Seal Repair Kits

Hydraulic systems play a crucial role in various industrial applications, from construction machinery to automotive equipment. One essential component ensuring the smooth operation of these systems is the hydraulic seal. Over time, these seals can wear out or become damaged, leading to leaks and reduced functionality. This is where hydraulic seal repair kits come into play, providing a cost-effective solution for maintaining and restoring hydraulic systems.

What is a Hydraulic Seal Repair Kit?

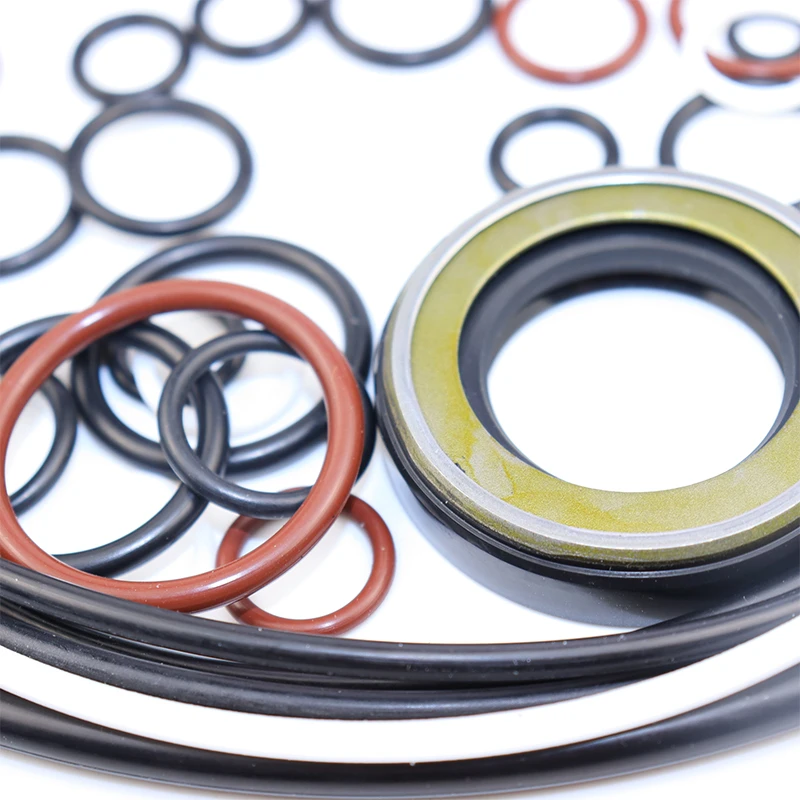

A hydraulic seal repair kit typically contains a variety of seals, O-rings, and backup rings designed to replace worn or damaged components within hydraulic cylinders, pumps, and other hydraulic equipment. The kits may also include specialized tools and lubricants to facilitate the repair process. By using a repair kit, machinery operators avoid the costly downtime associated with complete system overhauls and can restore equipment functionality efficiently.

Types of Seals Included in Repair Kits

Hydraulic seal repair kits commonly include several types of seals, each tailored for specific applications

1. O-rings These circular seals are versatile and used to create a tight seal between two components, preventing fluid leakage. They come in various sizes and materials, such as nitrile or polyurethane.

3. Piston seals These seals are installed inside the cylinder and ensure that hydraulic pressure is maintained as the piston moves up and down.

4. Backup rings Used in conjunction with O-rings, backup rings provide additional support and prevent extrusion at high pressures.

hydraulic seal repair kit

Benefits of Using a Hydraulic Seal Repair Kit

1. Cost-effectiveness Repairing rather than replacing damaged seals can save significant amounts of money. The initial investment in a repair kit typically pays off through the prevention of more extensive repairs.

2. Convenience Repair kits allow users to perform repairs on-site, reducing the need for specialized tools or services.

3. Increased lifespan of equipment Regular maintenance with repair kits can prolong the life of hydraulic systems by preventing leaks and maintaining optimal performance.

4. Versatility Many kits are designed to cater to a variety of machinery and applications, making them an invaluable asset for operators dealing with multiple hydraulic systems.

Installation Tips

To maximize the effectiveness of a hydraulic seal repair kit, it's essential to follow some basic installation tips

- Always clean the surfaces thoroughly before installation to prevent contamination and ensure a proper seal. - Lubricate seals during installation to reduce friction and facilitate a smoother fit. - Follow manufacturer guidelines for specific torque settings and assembly sequences to avoid improper installation.

Conclusion

In conclusion, hydraulic seal repair kits are an indispensable resource for maintaining hydraulic systems. They offer a practical and cost-effective solution for repairs, ensuring that machinery runs efficiently and safely. By understanding the components of these kits and following best practices for installation, operators can significantly extend the lifespan of their hydraulic equipment and avoid costly downtime.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories