Sep . 03, 2024 21:05 Back to list

hydraulic cylinder seal repair

Hydraulic Cylinder Seal Repair A Comprehensive Guide

Hydraulic cylinders are critical components in various industrial applications, from construction equipment to manufacturing machinery. They convert hydraulic energy into mechanical force, facilitating countless operations. However, like any mechanical system, they are susceptible to wear and damage, particularly their seals. Seal failure can lead to leakage, reduced system efficiency, and potentially costly repairs. Understanding the process of hydraulic cylinder seal repair is essential for maintaining the longevity and performance of hydraulic systems.

Understanding Hydraulic Seals

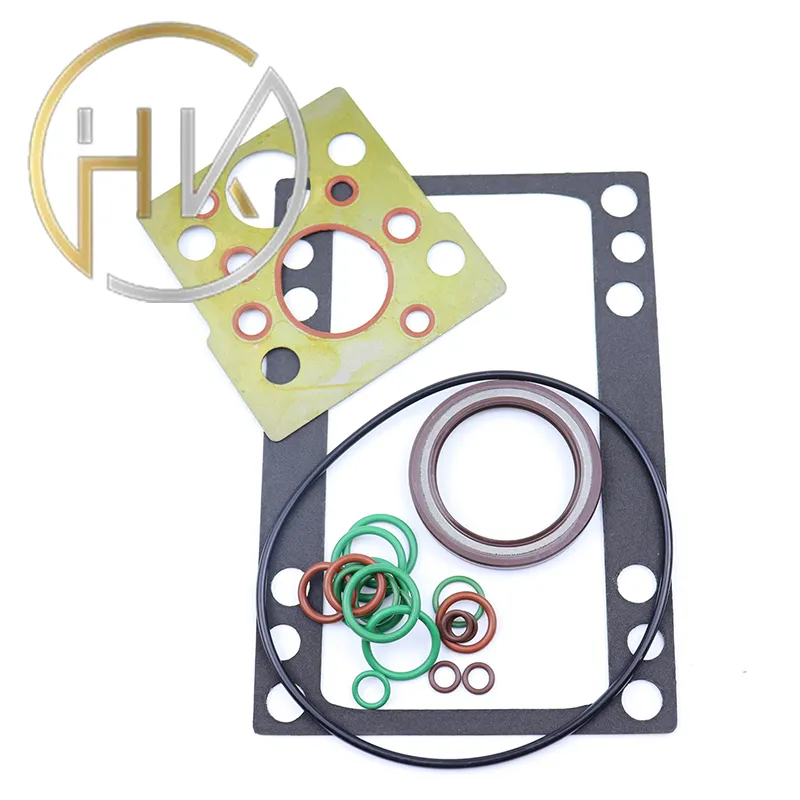

Hydraulic seals are designed to prevent fluid leaks between the moving and stationary parts of hydraulic cylinders. They must withstand high pressures, temperatures, and the abrasive nature of hydraulic fluids. Common types of seals used in hydraulic applications include O-rings, U-cups, and backup rings. Each type has specific properties suited for different applications, and selecting the right one is crucial for effective performance.

Signs of Seal Failure

Before diving into repair methods, it’s vital to recognize the signs of seal failure. Common indicators include

1. Fluid Leakage Visible hydraulic fluid around the cylinder indicates seal deterioration. 2. Reduced Performance A decline in the speed or power of the hydraulic system can signify internal leaks due to seal failure. 3. Increased Operating Noise Unusual sounds during operation may suggest that the seals are not functioning correctly.

Repairing Hydraulic Cylinder Seals

hydraulic cylinder seal repair

When faced with seal failure, prompt action is necessary to minimize downtime and prevent further damage. Here’s a step-by-step guide to repairing hydraulic cylinder seals

1. Diagnostic Inspection Begin by inspecting the hydraulic cylinder to determine the extent of the damage. Look for signs of wear, corrosion, or debris in the cylinder.

2. Disassembly Carefully remove the cylinder from the equipment. Follow safety protocols to avoid injury or excessive wear to other components. Clean the cylinder thoroughly before proceeding.

3. Seal Replacement Remove the old seals using appropriate tools, ensuring that no debris enters the cylinder. Clean the grooves and inspect for damage. Select the correct replacement seals based on your assessment.

4. Reassembly Install the new seals, ensuring they fit securely within the grooves. Reassemble the hydraulic cylinder, making sure all components are aligned correctly.

5. Testing Once reassembled, conduct a pressure test to ensure the seals function properly and that there are no leaks. Monitor the system during initial operation for any signs of failure.

Conclusion

Repairing hydraulic cylinder seals is a critical maintenance task that can significantly impact a hydraulic system’s performance and longevity. By recognizing the signs of seal failure and following proper repair procedures, operators can ensure their machinery runs efficiently, reducing the risk of unexpected breakdowns. Staying proactive with maintenance not only saves on repair costs but also enhances the overall productivity of hydraulic systems. Whether you’re a seasoned mechanic or a machine operator, understanding hydraulic seal repair is an invaluable skill in today’s industrial landscape.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories