Aug . 19, 2024 23:33 Back to list

Hydraulic Cylinder Repair Kits for Efficient Maintenance and Performance Enhancement

Repairing Hydraulic Cylinder Kits A Comprehensive Guide

Hydraulic cylinders are essential components in various machinery, from construction equipment to manufacturing processes. Over time, these cylinders can wear out or become damaged due to various factors, such as excessive pressure, contamination, and lack of maintenance. Repairing hydraulic cylinder kits is a cost-effective solution that not only extends the lifespan of the machinery but also enhances operational efficiency. This article explores the steps and considerations involved in repairing hydraulic cylinder kits.

Understanding Hydraulic Cylinder Kits

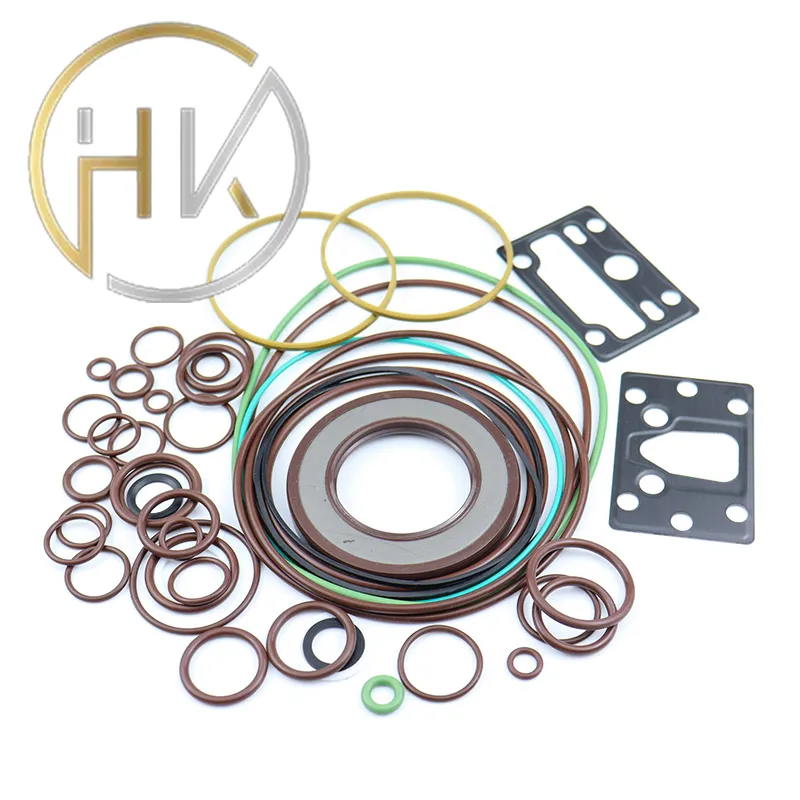

A hydraulic cylinder kit typically includes various components essential for the proper functioning of the hydraulic system. This can include seals, o-rings, wipers, and other related parts. These kits are designed to replace worn-out components, thereby restoring the hydraulic cylinder’s performance. Understanding the specific parts included in a hydraulic cylinder kit is crucial before embarking on any repair work.

Identifying the Issues

Before you can repair a hydraulic cylinder, you need to identify the problems. Common issues include leaks, poor performance, and physical damage to the cylinder body. Start by conducting a visual inspection of the cylinder for any signs of leakage or corrosion. Additionally, you may need to operate the machinery to observe any performance issues, such as lagging response times or unexpected movements.

Gathering Necessary Tools and Equipment

Once the issues have been identified, it's time to gather the necessary tools and equipment. Typical tools for hydraulic cylinder repair include

- Wrenches and sockets - Screwdrivers - Pliers - A seal puller - A torque wrench - Safety gear (gloves, goggles, etc

.)Additionally, having a clean workspace is vital for ensuring that no contaminants enter the hydraulic system during the repair process.

hydraulic cylinder kits repair

Steps to Repair the Hydraulic Cylinder Kit

1. Disassemble the Cylinder Start by carefully removing the cylinder from the machinery. This may require detaching it from hoses, mounts, and other components. Be cautious to avoid damaging any parts during disassembly.

2. Inspect Components Once disassembled, inspect all the components of the hydraulic cylinder, including the rod, barrel, and end caps. Identify any parts that are damaged and need replacement.

3. Replace Worn Seals and O-Rings Using a seal puller, remove old seals and o-rings carefully. Clean the grooves where the seals sit to ensure a snug fit for the new components. Install the new seals and o-rings, making sure they are properly seated.

4. Clean the Cylinder Thoroughly clean the interior and exterior of the cylinder. This step is critical to prevent contamination, which can lead to premature failure of the hydraulic system.

5. Reassemble the Cylinder Once everything is clean and new seals are in place, reassemble the cylinder. Be sure to follow the manufacturer’s specifications for torque settings to ensure proper assembly.

6. Test the Cylinder After reassembly, it's time to test the hydraulic cylinder. Reinstall it back into the machinery and run the system to check for leaks and ensure proper functionality. Pay attention to the performance to confirm that the repairs have resolved the initial issues.

Conclusion

Repairing hydraulic cylinder kits can significantly reduce operational costs and downtime in equipment. However, it requires careful inspection, the right tools, and a methodical approach. By following the steps outlined in this guide and understanding the components involved, you can successfully repair hydraulic cylinder kits and restore equipment to peak performance. Regular maintenance and timely repairs are crucial in prolonging the life of hydraulic systems, ensuring that machinery operates effectively and safely for years to come.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories