Sep . 04, 2024 17:04 Back to list

hydraulic cylinder repair kits

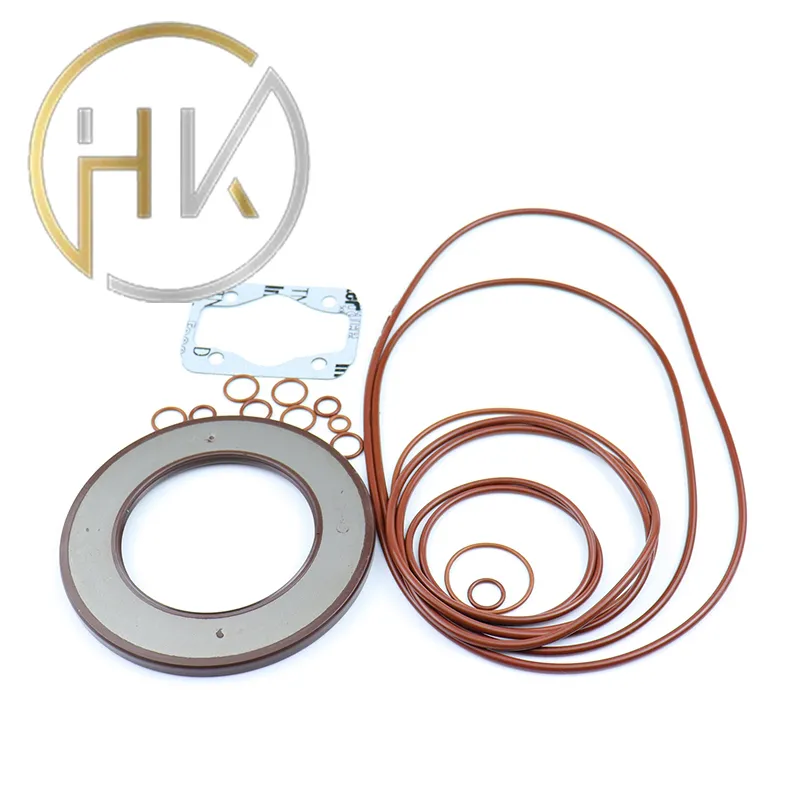

Understanding Hydraulic Cylinder Repair Kits

Hydraulic cylinders are essential components in various industrial and construction applications, providing the power needed for lifting, pushing, and pulling heavy loads. However, like any mechanical system, they can encounter wear and tear due to prolonged use. When a hydraulic cylinder starts to leak or perform poorly, a repair kit can be an efficient and cost-effective solution.

A hydraulic cylinder repair kit typically includes all the necessary components required to restore the cylinder’s functionality. These kits often consist of seals, O-rings, piston seals, wipers, and other essential parts. The specific contents may vary based on the make and model of the hydraulic cylinder, emphasizing the importance of choosing a kit that is compatible with your equipment.

The benefits of using a repair kit are manifold. First and foremost, repairing a hydraulic cylinder with a quality kit can extend the life of the equipment significantly. By replacing worn seals and components, operators can prevent further damage that might lead to more extensive repairs or even total replacement of the hydraulic cylinder. Furthermore, utilizing a repair kit often proves to be more economical than investing in a new cylinder, which can be a substantial expense.

hydraulic cylinder repair kits

Before embarking on a repair, it’s crucial to conduct a complete assessment of the hydraulic system. Identifying the root cause of the failure—be it contamination, incorrect installation, or lack of maintenance—can help prevent future issues. Additionally, proper installation of the repair kit components is vital. Even the best quality parts will fail if not properly fitted.

Maintenance is also key to the longevity of hydraulic cylinders. Regular inspections and servicing can help spot potential problems before they escalate. Implementing a preventive maintenance schedule can facilitate timely repairs that keep your hydraulic systems running smoothly.

In summary, hydraulic cylinder repair kits present a practical and cost-efficient solution for restoring hydraulic systems. With the right tools, components, and maintenance practices, businesses can ensure their hydraulic equipment continues to perform at its best, minimizing downtime and maximizing productivity. Investing in quality repair kits and adhering to a strict maintenance schedule will ultimately contribute to the overall efficiency and effectiveness of hydraulic operations.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories