Sep . 02, 2024 14:45 Back to list

hydraulic cylinder repair kits

Hydraulic Cylinder Repair Kits A Comprehensive Guide

Hydraulic systems are essential components in various industries, providing the necessary power for machinery to operate efficiently. Among the critical parts of these systems are hydraulic cylinders, which convert hydraulic energy into linear motion. However, like any mechanical component, hydraulic cylinders can wear out over time due to constant use, pressure fluctuations, and exposure to various elements. This is where hydraulic cylinder repair kits come into play, offering a practical solution for maintaining and repairing these vital components.

Understanding Hydraulic Cylinder Wear and Tear

Hydraulic cylinders typically encounter issues such as leaks, reduced performance, and physical damage. Common causes include contamination from dirt and debris, fluid leaks from seals, and wear on the cylinder walls. Addressing these problems swiftly is crucial, as neglecting them can lead to more severe machinery failures and costly downtimes. Repairing a cylinder through a dedicated kit can often be more economical and environmentally friendly than replacing the entire unit.

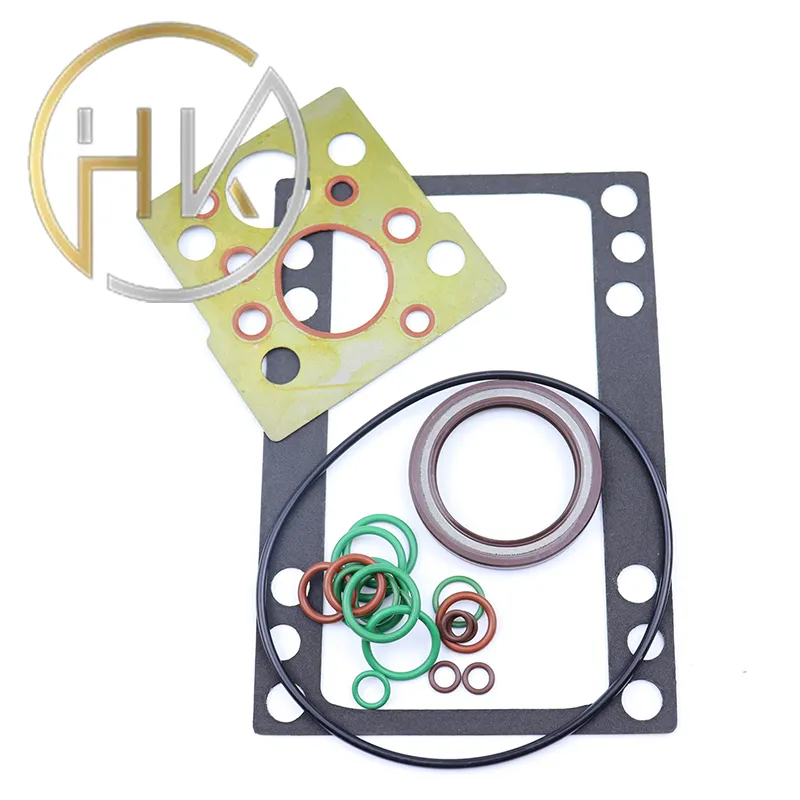

Components of a Hydraulic Cylinder Repair Kit

A typical hydraulic cylinder repair kit includes various components necessary for restoring the cylinder’s functionality. These may consist of

1. Seals and O-rings Seals are vital for preventing fluid leaks. Different types of seals, such as rod seals and piston seals, ensure airtight isolation. O-rings, made from various materials, help maintain pressure and protect against leakage.

3. Piston and Rod Heads In some kits, replacement piston and rod heads are included to resolve issues related to wear or damage.

hydraulic cylinder repair kits

4. Dust Seals Dust seals prevent dirt and debris from entering the cylinder, which can cause internal damage. These are crucial for extending the repair's lifespan.

5. Lubrication Many kits include specific lubricants designed to enhance seal performance and longevity, ensuring smooth operation.

Choosing the Right Repair Kit

When selecting a hydraulic cylinder repair kit, several factors should be considered

- Compatibility It's essential to choose a kit that matches the specific make and model of your hydraulic cylinder. Different cylinders have unique configurations, and using an incompatible kit can lead to further damage.

- Quality of Components Opt for high-quality materials that can withstand the rigors of hydraulic systems. Kits from reputable manufacturers are often tested for durability and performance.

- Ease of Installation Some repair kits come with detailed installation instructions, making it easier for users to complete repairs themselves, thus saving on labor costs.

Conclusion

Hydraulic cylinder repair kits are invaluable for maintaining the efficacy and functionality of hydraulic systems. By understanding the components included and choosing the right kit based on compatibility and quality, operators can avoid costly replacements and extend the life of their hydraulic cylinders. Timely repairs not only ensure smooth operations but also contribute to the overall efficiency and productivity of industrial machinery. Investing in these repair kits is a proactive step toward effective maintenance, ultimately leading to reduced downtime and enhanced performance in demanding industrial environments.

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

Products categories