Nov . 25, 2024 05:40 Back to list

Understanding Hydraulic Cylinder Seals in Fluid Power Applications and Their Importance

Hydraulic Cylinder Seals The Unsung Heroes of Fluid Power Systems

Hydraulic cylinders play a vital role in various industries, facilitating the controlled movement of machinery and equipment. However, the efficiency and longevity of these cylinders heavily rely on an often-overlooked component seals. Hydraulic cylinder seals ensure that the hydraulic fluid remains contained within the cylinder, preventing leaks and maintaining pressure. In this article, we will explore the various types of hydraulic cylinder seals, their functions, and the importance of selecting the right seals for optimal performance.

Types of Hydraulic Cylinder Seals

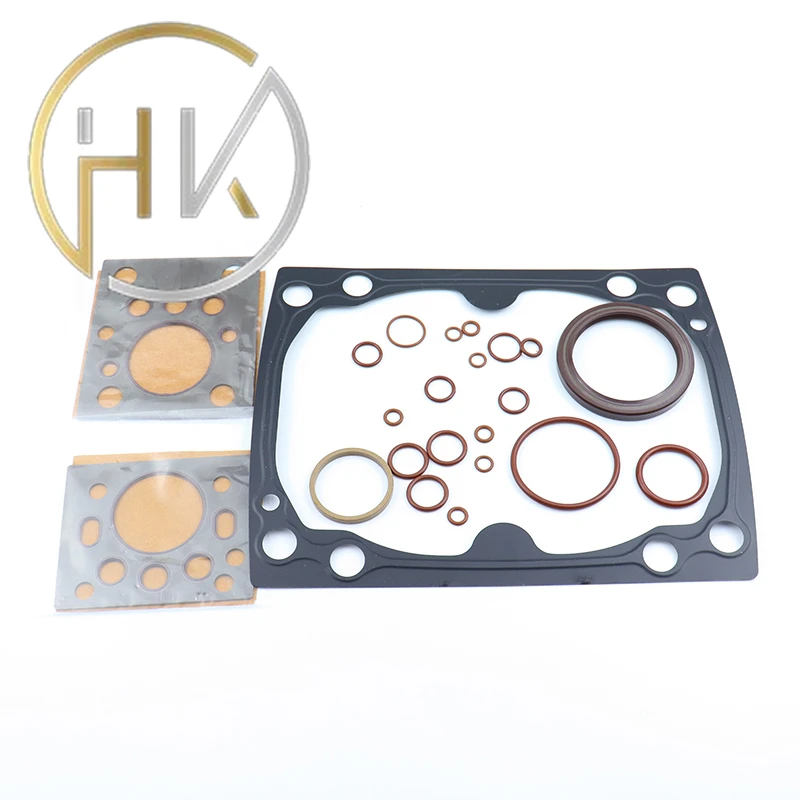

Hydraulic cylinder seals can be broadly categorized into two main types static seals and dynamic seals. Static seals are used in applications where there is no relative motion between parts, while dynamic seals are designed for moving components.

1. Static Seals These seals prevent fluid leakage between stationary components. Examples of static seals include O-rings, gaskets, and flat seals. O-rings are particularly popular due to their versatility and reliability. Made from materials like nitrile or fluorocarbon, O-rings can withstand high pressures and temperatures, making them suitable for various hydraulic applications.

2. Dynamic Seals These seals are essential for areas where there is relative motion. They are designed to accommodate movement without sacrificing sealing performance. Common dynamic seals include rod seals, piston seals, and wiper seals. Rod seals, for instance, are placed on the cylinder rod to prevent fluid from leaking out, while piston seals keep fluid from entering the cylinder's internal space from the outside.

Functions of Hydraulic Cylinder Seals

The primary function of hydraulic cylinder seals is to maintain pressure and prevent fluid leakage

. However, they also serve other critical functions- Wear Protection Seals protect the moving parts of hydraulic cylinders from wear and tear caused by contamination and foreign particles. A good seal minimizes the risk of dirt and debris entering the system, which can lead to premature failure.

hyd cylinder seals

- Efficient Operation Proper sealing allows hydraulic systems to operate efficiently. By preventing leaks, seals help maintain pressure, ensuring that machines operate at their optimal performance levels.

- Energy Conservation In hydraulic systems, energy loss due to fluid leakage can lead to increased operational costs. Properly functioning seals help conserve energy and reduce expenses.

Importance of Selecting the Right Seals

Choosing the right hydraulic cylinder seals is crucial for the performance and reliability of hydraulic systems. Several factors must be considered during selection, including

- Material Compatibility Different hydraulic fluids can have varying effects on seal materials. It’s essential to select seals made from materials that are compatible with the specific hydraulic fluid being used.

- Operating Conditions The temperature, pressure, and environment in which the seals will operate must be evaluated. Seals should be able to withstand the operating conditions to ensure longevity and performance.

- Application Requirements Different applications may require specific sealing solutions. Understanding the application’s requirements helps in choosing the most suitable seal type.

Conclusion

Hydraulic cylinder seals are critical components that ensure the efficient and reliable operation of hydraulic systems. Their ability to prevent leaks, protect against wear, and maintain energy efficiency underscores their importance in various industrial applications. By understanding the different types of seals and the factors influencing their selection, engineers and maintenance professionals can ensure the optimal performance and longevity of hydraulic equipment. Investing in quality seals ultimately leads to reduced downtime, lower maintenance costs, and improved operational efficiency, making them the unsung heroes of fluid power systems.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories