Oct . 07, 2024 01:40 Back to list

hyd cylinder seals

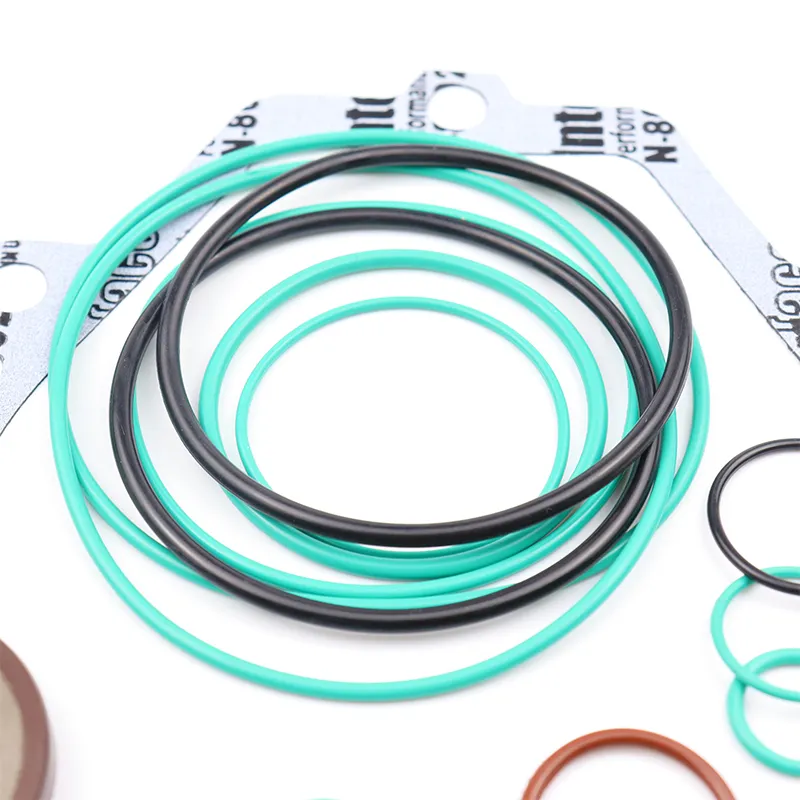

Understanding Hydraulic Cylinder Seals Key Components for Optimal Performance

Hydraulic systems play a critical role in various industries, including manufacturing, construction, and automotive. One of the essential components that ensure the efficient operation of hydraulic systems is the hydraulic cylinder seal. These seals help maintain pressure, prevent leaks, and enhance the overall performance of hydraulic cylinders. This article will explore the importance of hydraulic cylinder seals, the different types available, and the factors to consider when selecting the right seal for a specific application.

The Importance of Hydraulic Cylinder Seals

Hydraulic cylinders are crucial in converting hydraulic energy into mechanical energy. They require a variety of seals to operate effectively, as any failure in sealing can lead to significant operational issues. The primary functions of hydraulic cylinder seals include

1. Fluid Containment Seals are designed to prevent hydraulic fluid from escaping the cylinder. Leaks can lead to decreased system efficiency, environmental hazards, and increased operational costs.

2. Pressure Maintenance Seals help maintain the necessary pressure within the hydraulic system. Efficient sealing ensures that pressure is sufficient to perform the required work without exhausting the hydraulic pump.

3. Contaminant Prevention Hydraulic systems are vulnerable to contaminants such as dirt and debris. Seals act as barriers, preventing these contaminants from entering the hydraulic cylinder and causing wear or damage.

4. Extending Lifespan High-quality seals contribute to the longevity of hydraulic cylinders. Proper sealing reduces wear and tear on internal components, leading to fewer maintenance needs and extending the overall lifespan of the equipment.

Types of Hydraulic Cylinder Seals

There are several types of hydraulic cylinder seals, each suited for specific applications. Understanding these types can help in selecting the right seal for your needs

1. Rod Seals These seals are located at the top of the cylinder and prevent hydraulic fluid from leaking out as the rod moves in and out. Common materials for rod seals include polyurethane and nitrile.

2. Piston Seals Located within the piston, these seals ensure that the hydraulic fluid can exert force on the piston without leaking. Piston seals are often made from materials that can withstand high pressure and temperature.

hyd cylinder seals

3. Buffer Seals Buffer seals are used to protect rod seals from pressure spikes and extrusions. They absorb shocks and help maintain the integrity of the rod seal.

4. Guide Rings While not seals in the traditional sense, guide rings help align the piston and rod within the cylinder. They reduce friction and wear, thus enhancing the performance of the hydraulic system.

Selecting the Right Hydraulic Cylinder Seal

Choosing the correct seal for a hydraulic cylinder requires careful consideration of various factors

1. Operating Conditions Examine the temperature, pressure, and type of hydraulic fluid in use. Different materials have varying resistance to temperature and chemical compatibility.

2. Dynamic vs. Static Applications Determine whether the seals will be used in dynamic applications (where there is continuous movement) or static applications (where components remain stationary). This can affect the type and design of the seal chosen.

3. Material Selection The material of the seal is crucial for performance. Common materials include nitrile, polyurethane, and PTFE (Teflon). Each material has its properties, such as hardness, wear resistance, and thermal stability.

4. Assembly and Installation Proper assembly and installation of seals are critical to their performance. Ensuring that seals are installed correctly can prevent premature wear and failure.

5. Cost and Quality While cost is an important factor, quality should not be compromised. Investing in high-quality seals can save costs in the long run by reducing maintenance issues and downtime.

Conclusion

Hydraulic cylinder seals are indispensable components that significantly contribute to the efficiency and longevity of hydraulic systems. Understanding their function, types, and selection criteria is essential for maintaining optimal performance in various applications. By choosing the right hydraulic cylinder seals, businesses can reduce leaks, maintain pressure, and protect against contaminants, ultimately leading to greater productivity and cost savings. Investing in quality seals and adhering to proper maintenance practices will ensure that hydraulic systems operate smoothly and efficiently for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories