Dec . 16, 2024 20:03 Back to list

Hydraulic Cylinder Seal Kit Replacement and Maintenance Guide for Optimal Performance

Understanding Hydraulic Cylinder Seal Kits Essential Components for Optimal Performance

Hydraulic cylinders play a crucial role in various industrial and mechanical applications, providing the necessary force to move heavy loads and perform intricate tasks. However, the efficiency and longevity of these cylinders are heavily dependent on the integrity of their seal kits. This article delves into the importance of hydraulic cylinder seal kits, their components, and maintenance practices that ensure optimal performance.

What is a Hydraulic Cylinder Seal Kit?

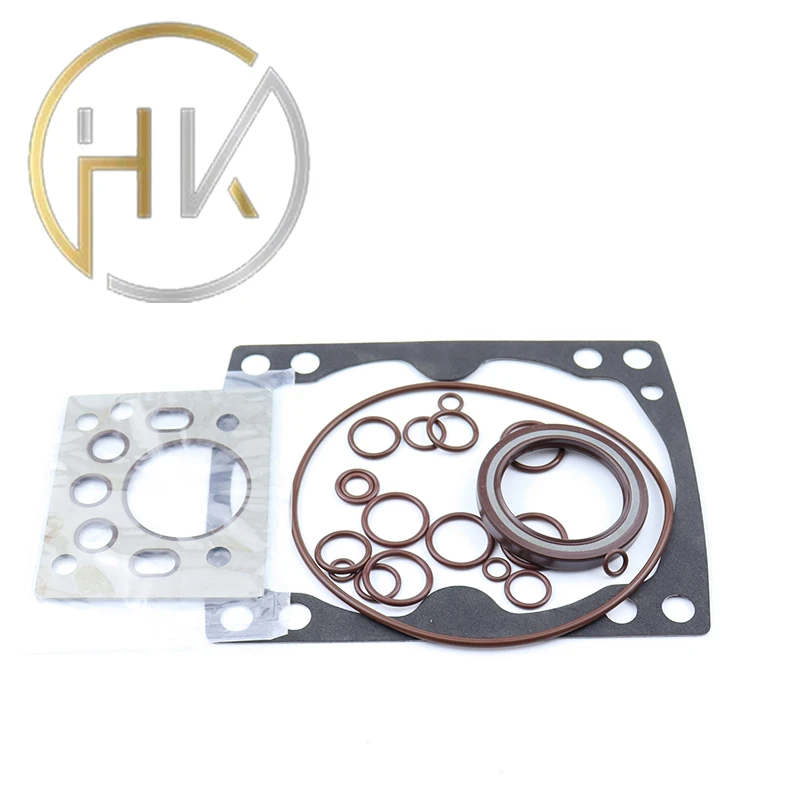

A hydraulic cylinder seal kit is a collection of seals and other related components designed to prevent hydraulic fluid from leaking out of the cylinder and to protect the internal components from contaminants. These kits are integral to the smooth operation of hydraulic systems, which are widely used in construction machinery, automotive applications, and manufacturing equipment.

Key Components of a Seal Kit

1. Piston Seals These seals are located between the piston and the cylinder wall. They prevent hydraulic fluid from leaking past the piston while under pressure, ensuring that the cylinder operates efficiently and delivers the intended force.

2. Rod Seals Rod seals are situated at the cylinder's exit point, sealing the gap between the piston rod and the cylinder body. This prevents hydraulic fluid from escaping as the rod extends and retracts and also protects the internal components from dirt and debris.

3. Backup Rings These components work in conjunction with piston and rod seals. They provide additional support and prevent seal extrusion under high-pressure conditions, enhancing the durability of the seal system.

4. Wear Rings Positioned on the piston and cylinder, wear rings reduce friction and wear between moving parts, prolonging the lifespan of the seals and improving overall performance.

5. O-Rings Versatile and commonly used in seal kits, O-rings are circular seals made of elastomer materials. They are typically used to seal static and dynamic applications, providing a tight seal against fluid leakage.

Importance of Seal Kits in Hydraulic Systems

hyd cylinder seal kit

The integrity of the hydraulic seals directly impacts the overall performance of the hydraulic system. If seals fail, hydraulic fluid can leak, leading to system inefficiencies, reduced force output, and increased maintenance costs. Moreover, external contaminants can enter the hydraulic system, causing wear and tear on internal components and ultimately leading to system failure.

The presence of a reliable hydraulic cylinder seal kit not only enhances the performance and efficiency of the hydraulic system but also ensures safety by preventing unexpected leaks that could lead to accidents.

Maintenance Tips for Hydraulic Cylinder Seal Kits

To optimize the performance and lifespan of hydraulic cylinder seal kits, regular maintenance is essential. Here are some tips

1. Inspection Regularly inspect the seals for signs of wear, damage, or seepage. Early detection of seal failure can prevent costly repairs and downtime.

2. Cleanliness Maintain a clean environment around the hydraulic cylinder. Dust, dirt, and debris can compromise seal integrity, so regular cleaning is imperative.

3. Proper Installation Ensure that seals are correctly installed according to the manufacturer’s specifications. Incorrect installation can lead to premature seal failure and hydraulic system malfunctions.

4. Fluid Quality Use high-quality hydraulic fluids compatible with the seal materials. Contaminated or inappropriate fluids can degrade the seals and the hydraulic system.

5. Temperature Control Monitor the operating temperature of the hydraulic system. Excessive heat can cause seals to harden or wear out more quickly.

Conclusion

Hydraulic cylinder seal kits are vital components that ensure the efficient and reliable operation of hydraulic systems. By understanding the different elements of a seal kit and committing to routine maintenance, operators can enhance the performance and lifespan of their hydraulic cylinders. Investing time and resources into maintaining these components not only saves costs in the long run but also ensures safety and operational efficiency across various applications. Whether you are in construction, manufacturing, or any industry reliant on hydraulic systems, prioritizing seal kit integrity is essential for achieving optimal results.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories