Nov . 23, 2024 14:59 Back to list

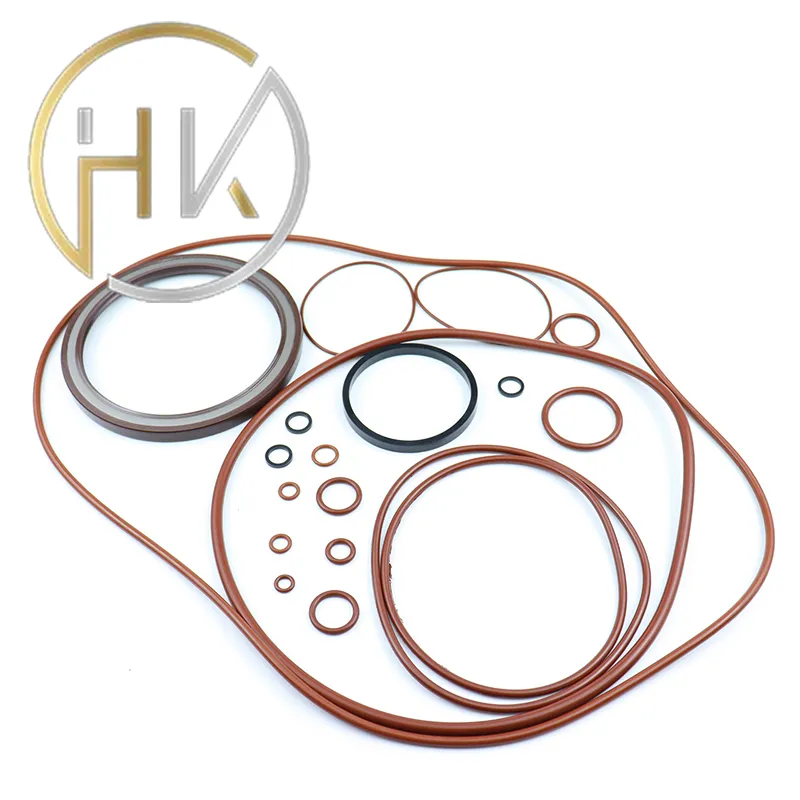

High-Performance Rubber Seals for Optimal Hub Protection and Durability

The Significance of Hub Rubber Seals in Modern Engineering

In modern engineering and manufacturing, the role of seals cannot be overstated. Among the various types of seals, hub rubber seals are particularly vital due to their versatility and essential function in ensuring the integrity of mechanical systems. These seals, designed to fit snugly around the hubs of various machinery and equipment, provide a myriad of benefits that are crucial for the optimal operation of mechanical components.

At its core, a hub rubber seal serves to prevent the leakage of fluids or the ingress of contaminants, thus protecting the internal mechanisms of machines from potential damage. This sealing mechanism is especially important in industries such as automotive, aerospace, and industrial machinery, where the reliability of the machinery is essential for performance and safety. The failure of seals can lead to catastrophic consequences, including equipment breakdowns or safety hazards, underscoring the importance of high-quality rubber seals in designs.

One of the main advantages of hub rubber seals is their flexibility and adaptability. Made from various types of rubber compounds, these seals can be tailored to meet specific performance requirements. For instance, different formulations can be used to enhance resistance to oils, chemicals, and extreme temperatures. This adaptability allows engineers to select materials that best fit the operational environment of their machinery, ensuring effective sealing under diverse conditions.

Moreover, hub rubber seals contribute to the efficiency of machinery. When properly installed, these seals minimize the friction between moving parts, leading to reduced wear and tear. This is particularly important in automotive applications, where excessive friction can lead to increased fuel consumption and decreased overall efficiency. By maintaining a tight seal, these rubber components help to optimize the performance of engines and other mechanical systems, ultimately leading to cost savings and enhanced productivity.

hub rubber seal

The installation and maintenance of hub rubber seals play a crucial role in their overall effectiveness. Adequate training for personnel involved in the installation process is necessary to ensure that seals are fitted correctly. A poorly installed seal can lead to leaks, which not only compromise the machinery's functionality but also can result in costly repairs and downtime. Regular inspections and maintenance are equally important, allowing for the early detection of wear or damage, and enabling timely replacements to uphold operational integrity.

In addition to their functional benefits, hub rubber seals also contribute to the sustainability of mechanical systems. By reducing leakage and contamination, these seals help to minimize waste and preserve natural resources. In an era where environmental consciousness is more significant than ever, the ability of rubber seals to enhance the longevity of equipment and reduce operational costs aligns with eco-friendly practices in engineering and manufacturing industries.

As technology continues to advance, so too do the designs and applications of hub rubber seals. Manufacturers are now experimenting with new materials and innovative sealing technologies to further enhance the performance and durability of these components. For example, the integration of advanced elastomeric materials and composite structures has led to the creation of seals that can withstand harsher conditions and provide even better resistance to wear and tear.

In conclusion, hub rubber seals play an indispensable role in the functionality and longevity of mechanical systems across various industries. Their ability to prevent leaks, minimize friction, and adapt to different environments makes them an essential component in modern engineering designs. As technology advances and the demand for higher efficiency and sustainability grows, it is clear that the importance of hub rubber seals will only continue to increase, driving innovation and enhancing performance in the mechanical systems of tomorrow. The seamless operation of countless machines today heavily relies on these small yet mighty components, making hub rubber seals a pillar of successful engineering practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories