Nov . 19, 2024 22:24 Back to list

hub rubber seal

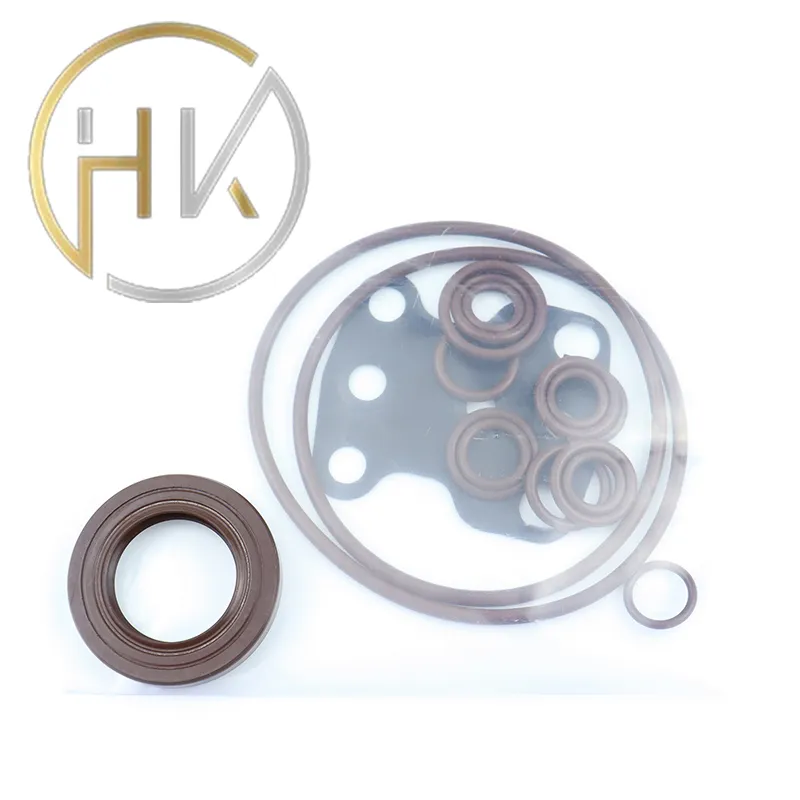

Understanding Hub Rubber Seals Functions and Benefits

Hub rubber seals play a crucial role in various mechanical systems, particularly in automotive and industrial applications. These seals serve as a barrier between different components, preventing the ingress of dirt, dust, moisture, and other contaminants that can compromise the integrity and functionality of the system. In this article, we delve into the essential functions, types, and benefits of hub rubber seals.

What Are Hub Rubber Seals?

Hub rubber seals are specially designed components used to maintain the integrity of hubs in vehicles, machinery, and equipment. They are typically made from elastomeric materials, which provide a flexible yet durable barrier. The primary function of these seals is to ensure that lubricants remain contained within a system while keeping external contaminants at bay.

Key Functions of Hub Rubber Seals

1. Contaminant Prevention By providing a robust seal around the hub, these rubber seals prevent dirt, dust, and moisture from penetrating into the machinery. This is essential for maintaining optimal performance and longevity.

2. Lubrication Retention Hub rubber seals effectively contain lubricants, ensuring that moving parts remain sufficiently lubricated and reducing friction. This helps in minimizing wear and tear, enhancing the lifespan of components.

3. Vibration Damping The flexible nature of rubber seals allows them to absorb vibrations, reducing noise and contributing to a smoother operation within machinery and vehicles.

4. Pressure Regulation In certain applications, hub rubber seals assist in maintaining pressure within systems. This is particularly important in hydraulic systems where pressure stability is critical for operation.

Types of Hub Rubber Seals

hub rubber seal

There are various types of hub rubber seals tailored for specific applications. Common varieties include

- O-Ring Seals These circular rubber seals are widely used for their versatility and reliable sealing capabilities in various industrial applications.

- Lip Seals Featuring a lip that contacts the shafts, these seals are particularly effective in preventing fluid leaks and are commonly used in automotive hubs.

- Mechanical Seals Often found in high-pressure applications, these seals combine various materials and designs to provide superior sealing performance.

Benefits of Using Hub Rubber Seals

Utilizing hub rubber seals offers several advantages

- Extended Equipment Lifespan By preventing contamination and retaining lubrication, these seals help extend the life of equipment and reduce maintenance costs.

- Enhanced Performance With effective sealing, machinery operates more efficiently, resulting in improved performance and reliability.

- Cost-Effectiveness Investing in high-quality hub rubber seals can lead to significant savings by reducing downtime and repair costs associated with contaminant damage.

In conclusion, hub rubber seals are essential components in maintaining the functionality and longevity of mechanical systems. Their ability to prevent contaminants, retain lubricants, and absorb vibrations makes them indispensable in various applications. Understanding their functions and benefits can help industries optimize their equipment and ensure reliable operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories