Dec . 13, 2024 04:02 Back to list

Understanding the Functionality and Importance of Hub Grease Seals in Machinery

Understanding Hub Grease Seals Essential Components in Automotive Applications

In the realm of automotive engineering, the hub grease seal is a fundamental component that often goes unnoticed but plays a crucial role in maintaining the efficiency and longevity of vehicles. These seals are designed to prevent the leakage of grease or oil from the wheel hub while also keeping contaminants such as water, dirt, and debris from entering the system. Understanding the function, types, and maintenance of hub grease seals can significantly impact vehicle performance and safety.

The Function of Hub Grease Seals

Hub grease seals serve a dual purpose retaining lubrication and protecting components. Inside the wheel hub, bearings need to be adequately lubricated to reduce friction and heat during operation. The grease seal prevents this lubricant from escaping, ensuring that the bearings remain well-lubricated and function smoothly. At the same time, a well-functioning grease seal blocks harmful contaminants, which can lead to premature wear or damage to bearings and other internal components.

In addition to these protective functions, hub grease seals help maintain the integrity of the wheel assembly. A failing seal can result in grease leakage, leading to inadequate lubrication, which may ultimately cause bearing failure. This not only affects vehicle performance but can also lead to costly repairs and unsafe driving conditions.

Types of Hub Grease Seals

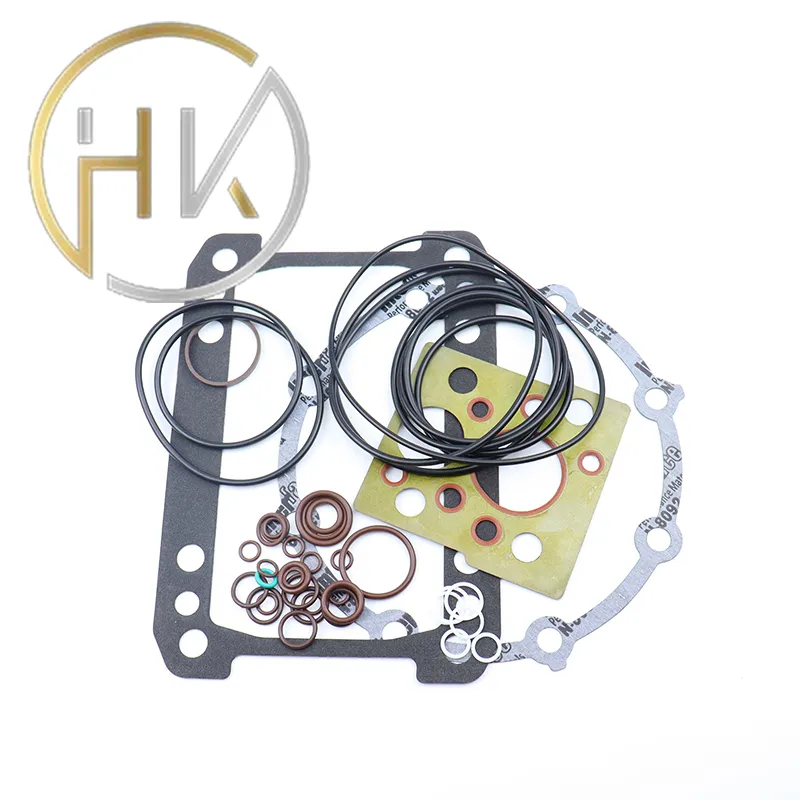

There are several types of hub grease seals, each designed for specific applications, materials, and environmental conditions

. The most common types include1. Rubber Seals These are made from synthetic rubber materials and are known for their flexibility and ability to conform to surfaces, providing a tight seal. Rubber seals are often used in passenger vehicles and light-duty trucks.

2. Metallic Seals Made from materials like stainless steel, these seals offer superior durability and are often employed in heavy-duty applications. They withstand extreme temperatures and pressures, making them suitable for commercial vehicles and off-road applications.

3. Composite Seals These seals combine rubber and metallic elements to provide a balance between flexibility and strength. They are versatile and can be used in various automotive applications.

hub grease seal

4. Spring-Loaded Seals Incorporating a spring mechanism, these seals maintain constant contact with the rotating shaft, providing a reliable barrier against contaminants and grease leakage.

Maintenance of Hub Grease Seals

Proper maintenance of hub grease seals is essential for ensuring their longevity and the overall health of the vehicle’s wheel assembly. Here are some maintenance tips

- Regular Inspections Periodically inspect the seals for signs of wear, cracking, or deformation. If leaks are detected, the seals should be replaced promptly to prevent damage to other components.

- Correct Installation Ensure that hub grease seals are installed correctly. Improper installation can lead to leaks and reduced effectiveness, so follow manufacturer guidelines carefully.

- Use Quality Lubrication Always use high-quality grease or oil recommended by the vehicle manufacturer. The right lubricant enhances the seal's effectiveness and reduces the risk of failure.

- Monitor Vehicle Performance Keep an eye on your vehicle's performance. Unusual noises, vibrations, or changes in handling can indicate problems with the hub assembly and necessitate further investigation.

Conclusion

Hub grease seals may seem like small components in a vast automotive system, but their role is indispensable. By containing lubrication and keeping contaminants at bay, these seals contribute significantly to the overall performance and safety of vehicles. Understanding their function, types, and maintenance can help vehicle owners make informed decisions about servicing and protecting their vehicles. In today’s automotive landscape, where efficiency and reliability are paramount, hub grease seals remain a crucial focus for manufacturers and enthusiasts alike. Ensuring their integrity not only prolongs the life of the vehicle but also enhances the driving experience, underscoring the importance of these often-overlooked components.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories