Nov . 09, 2024 16:50 Back to list

Understanding Hub Grease Seals and Their Importance in Vehicle Maintenance

Understanding Hub Grease Seals A Comprehensive Guide

In the world of machinery and automotive applications, the significance of proper lubrication cannot be overstated. At the heart of effective lubrication systems lies the hub grease seal, a vital component that plays an essential role in protecting vital machinery components from contamination while ensuring smooth operation. This article delves into the intricacies of hub grease seals, their functionality, types, maintenance, and the impact they have on machinery performance.

What Is a Hub Grease Seal?

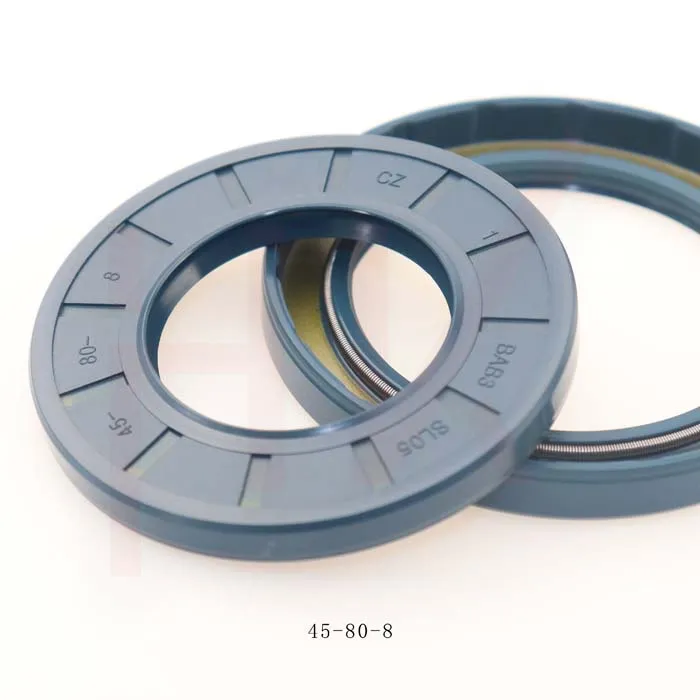

A hub grease seal is a robust sealing device typically installed around the wheel hub to prevent lubricants, such as grease or oil, from leaking out, while also protecting the components from external contaminants. This dual-action mechanism is crucial as it helps maintain the integrity of the lubrication system, which is paramount for minimizing wear and tear on moving parts.

Functionality of Hub Grease Seals

The primary function of a hub grease seal is to provide a barrier between the internal lubricants and the external environment. This includes dirt, water, dust, and other debris that can cause significant damage to bearings and other moving parts. By keeping contaminants at bay, grease seals prolong the life of machinery, reduce maintenance costs, and enhance overall performance.

Furthermore, hub grease seals maintain the appropriate pressure within the housing where the grease resides

. This pressure is vital for preventing leaks and ensuring that sufficient lubricant is available for optimal friction reduction. The seals also accommodate slight movements in the axle or hub, maintaining their sealing effectiveness even under varying load conditions.Types of Hub Grease Seals

There are various types of hub grease seals available, each designed for specific applications and performance requirements. The most common types include

hub grease seal

1. Single Lip Seals These are the simplest form of seals, consisting of a single lip that makes contact with the shaft. They are suitable for applications where there is minimal contamination risk and are commonly used in lighter-duty vehicles.

2. Double Lip Seals Featuring two sealing lips, these seals provide enhanced protection against dirt and moisture. The additional lip acts as a secondary barrier, making them ideal for more demanding environments.

3. Spring-Loaded Seals These seals incorporate a spring mechanism that ensures consistent contact with the shaft, providing an extra layer of sealing force. This type is particularly useful where there is a range of motion or vibration.

4. Polymer Seals Made from advanced materials, polymer seals offer superior resistance to chemicals, extreme temperatures, and abrasion. They are highly effective in harsh industrial environments.

Maintenance and Inspection

Regular maintenance and inspection of hub grease seals are crucial for ensuring the longevity and performance of machinery. Because these seals are exposed to a range of conditions, they can wear out over time. Signs that a grease seal may need replacement include oil or grease leakage, unusual noise from the wheel hub, and visible cracks or wear on the seal itself.

When conducting maintenance, it’s important to check not only the seal but also the condition of the hub and bearings. Proper lubrication levels should be maintained, and any contaminants should be cleaned from the area to prevent further damage.

Conclusion

In summary, hub grease seals are indispensable components in the realm of machinery and automotive systems. Their ability to maintain lubricant levels while preventing contamination is crucial for enhancing the durability and efficiency of various applications. Understanding the types, functionality, and maintenance of hub grease seals allows operators and technicians to optimize performance and prolong the lifespan of their equipment. Investing time in regular inspections and timely replacements can lead to significant financial savings and improved operational efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories