Dec . 12, 2024 12:24 Back to list

hub dust seal

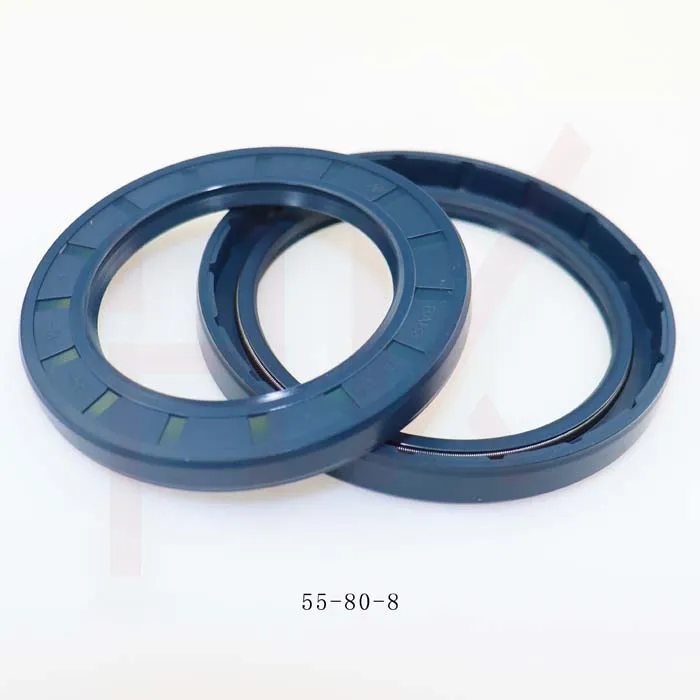

Understanding Hub Dust Seals Essential Components for Machinery Protection

In the realm of mechanical engineering and machinery design, the importance of protecting internal components from external contaminants cannot be overstated. One of the most critical components in achieving this protection is the hub dust seal. Often overlooked in discussions about machinery maintenance, hub dust seals play a vital role in ensuring longevity and optimal performance of equipment.

What is a Hub Dust Seal?

A hub dust seal is a sealing component that is typically located at the wheel hub of vehicles or machinery. Its primary function is to prevent dust, dirt, and other debris from entering the hub assembly, where essential moving parts such as bearings are located. By effectively blocking contaminants, these seals play a crucial role in reducing wear and tear and ensuring the smooth operation of rotating components.

Types of Hub Dust Seals

There are various types of hub dust seals, each designed to meet specific requirements and conditions. The most common types include

1. Rubber Seals These are typically made from elastomeric materials and provide excellent flexibility and durability. Rubber seals can accommodate slight misalignments and offer good resistance to abrasive particles.

2. Metal Seals In environments where extreme temperatures or harsh chemicals are present, metal seals may be used. They offer robust protection and can withstand high levels of stress.

3. Composite Seals A combination of materials, composite seals can provide the advantages of both rubber and metal. They can be tailored to suit specific applications, ensuring optimal performance.

Importance of Hub Dust Seals

hub dust seal

The significance of hub dust seals can be understood through several key aspects

1. Protection Against Contaminants The primary function of these seals is to keep harmful debris out of the machinery's critical areas. When dust and dirt penetrate the hub assembly, they can cause significant damage, potentially leading to costly repairs or even equipment failure.

2. Extended Equipment Life By preventing contaminants from causing premature wear on bearings and other moving parts, hub dust seals contribute to the overall longevity of machinery. This is particularly crucial in industries where downtime can impact productivity and profitability.

3. Improved Performance Clean and well-maintained components operate more efficiently. Hub dust seals help ensure that machinery maintains peak performance, reducing energy consumption and enhancing operational efficiency.

4. Safety In vehicles, malfunctioning hub dust seals can lead to compromised braking systems or wheel failures. By maintaining the integrity of the hub assembly, these seals play a vital role in ensuring the safety of both operators and equipment users.

Maintenance and Inspection

While hub dust seals are designed to last, regular maintenance and inspection are crucial to ensure their integrity and functionality. Signs of wear, such as cracks or deformation, should be addressed promptly. Furthermore, periodic lubrication of the hub assembly can enhance the lifespan of both the dust seals and internal components.

Conclusion

Hub dust seals may seem like minor components in the grand scheme of machinery design and maintenance, but their role is undeniably significant. By preventing the ingress of dirt and debris, they protect critical components, extend the life of machinery, and ensure safe and efficient operation. As industries continue to advance and machinery becomes more complex, understanding and maintaining hub dust seals will remain essential for optimal performance and durability. Investing in high-quality dust seals and adhering to maintenance schedules can save businesses both time and money, making them a worthy consideration in any machinery operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories