Aug . 21, 2024 12:51 Back to list

How to Replace Seals in a Hydraulic Cylinder Efficiently and Safely

Replacing Seals on a Hydraulic Cylinder A Comprehensive Guide

Hydraulic cylinders are crucial components in various industrial applications. They function by converting hydraulic energy into mechanical energy, allowing for precise control of force and movement. However, like any mechanical component, hydraulic cylinders can experience wear and tear, particularly on their seals. Replacing seals on a hydraulic cylinder is essential for maintaining its efficiency and prolonging its lifespan. This article provides a step-by-step guide on how to effectively replace seals on a hydraulic cylinder.

Understanding the Importance of Seals

The seals in a hydraulic cylinder serve several essential functions. They prevent hydraulic fluid from leaking out of the cylinder, which is vital for maintaining pressure and the overall functionality of the system. Additionally, seals protect the internal components from contaminants that can cause damage and reduce efficiency. Over time, seals can wear down due to friction, temperature fluctuations, and exposure to various chemicals. When this occurs, addressing the issue promptly is necessary to prevent more extensive damage to the hydraulic system.

Tools and Materials Required

Before starting the seal replacement process, gather the necessary tools and materials

1. Replacement seals compatible with your specific hydraulic cylinder model. 2. Basic hand tools such as wrenches, screwdrivers, and pliers. 3. Seal pullers or a suitable pry tool. 4. Cleaning solvent and rags for cleaning the cylinder. 5. Lubricant recommended for use with hydraulic seals, such as hydraulic oil.

Step-by-Step Seal Replacement Process

1. Preparation and Safety First Begin by ensuring the hydraulic cylinder is not under pressure. Disconnect the hydraulic lines and ensure the cylinder is immobilized. Always wear appropriate personal protective equipment, including gloves and safety goggles, for your protection.

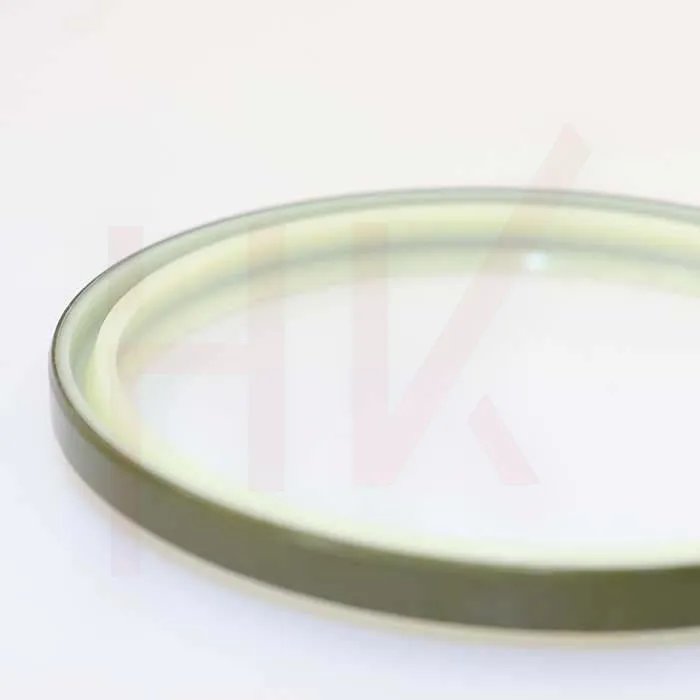

replacing seals on a hydraulic cylinder

2. Disassembly of the Cylinder Carefully remove the cylinder from its mounting. Use the appropriate tools to unscrew and separate the cylinder head from the barrel. Take care not to damage any external components during this process.

3. Removing Old Seals Once the cylinder is disassembled, locate the old seals. Use a seal puller or a pry tool to gently remove the worn seals from their grooves. Take care not to scratch or damage the cylinder surfaces or grooves, as this can lead to leaks.

4. Cleaning the Cylinder After removing the old seals, thoroughly clean the cylinder and all its components. Use a cleaning solvent and rags to remove dirt, debris, and any residue left from the old seals. Ensure that all surfaces are free from contaminants.

5. Installing New Seals Coat the new seals with a suitable lubricant. This makes it easier to install them and helps prevent damage during installation. Carefully place the new seals into their respective grooves, ensuring they are seated evenly and securely.

6. Reassembly Reassemble the hydraulic cylinder by carefully aligning the cylinder head and barrel. Use a wrench to tighten the screws to the manufacturer's specifications, ensuring that the cylinder is sealed properly.

7. Testing After reassembly, reconnect the hydraulic lines and fill the cylinder with hydraulic fluid if necessary. Test the hydraulic system to ensure everything operates smoothly and check for any leaks around the newly installed seals.

Conclusion

Replacing seals on a hydraulic cylinder is a straightforward yet vital maintenance task that requires attention to detail and proper technique. By following the steps outlined above, you can ensure your hydraulic cylinder operates at peak efficiency, reducing the risk of leaks and damage. Regular maintenance and timely seal replacement will not only enhance the performance of your hydraulic system but also extend its lifespan, ultimately saving you time and money in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories