Aug . 09, 2024 06:35 Back to list

How to Choose the Best Hydraulic Motor Rebuild Kit for Your Equipment Needs

Understanding Hydraulic Motor Rebuild Kits

Hydraulic motors are invaluable components in various industrial applications, converting hydraulic energy into mechanical power. Over time, like any mechanical system, these motors can wear down or fail, necessitating maintenance or replacement. This is where hydraulic motor rebuild kits come into play. These kits allow for the restoration of hydraulic motors to their full operational condition, providing a cost-effective solution compared to purchasing entirely new motors.

What is a Hydraulic Motor Rebuild Kit?

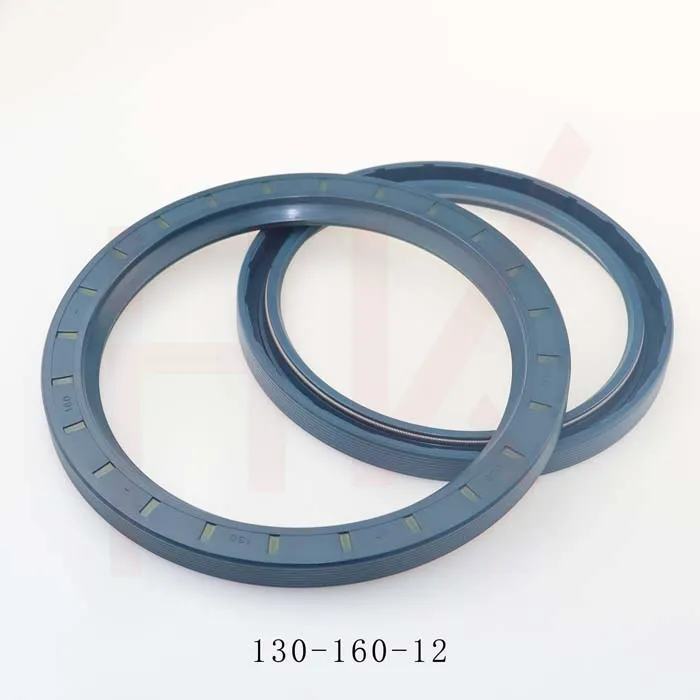

A hydraulic motor rebuild kit typically includes all the necessary components and tools required for overhauling a hydraulic motor. This may consist of O-rings, seals, bearings, pistons, and other vital parts. The specific contents of a rebuild kit can vary depending on the make and model of the hydraulic motor, but the primary aim remains the same to restore functionality and extend the life of the motor.

Benefits of Using a Rebuild Kit

1. Cost-Effectiveness One of the most significant advantages of using a rebuild kit is its cost-effectiveness. Purchasing a new hydraulic motor can be a considerable investment, frequently costing thousands of dollars. A rebuild kit, in contrast, often represents a fraction of that cost, allowing businesses to save money while maintaining operational efficiency.

2. Sustainability By choosing to rebuild rather than discard, companies contribute to environmental sustainability. Rebuilding reduces waste and gives old machinery a new lease on life, aligning with the growing emphasis on eco-friendly practices in manufacturing and construction.

3. Availability of Parts Often, manufacturers provide rebuild kits for hydraulic motors that may be outdated or difficult to find. This ensures that businesses can continue utilizing older equipment without being forced to bear the expense of upgrading to a newer model.

4. Improved Performance Rebuilding a hydraulic motor can restore it to peak performance. Over time, wear and tear can diminish a motor's power and efficiency. By replacing worn-out components with new ones from a rebuild kit, operators can often experience improved responsiveness, efficiency, and reliability.

hydraulic motor rebuild kit

How to Choose the Right Rebuild Kit

When selecting a rebuild kit for a hydraulic motor, several factors need consideration

- Compatibility The kit must be compatible with the specific model of hydraulic motor being serviced. Always refer to the motor's model number and specifications to ensure a proper fit.

- Quality of Components Not all rebuild kits are created equal. It's essential to source kits from reputable suppliers who use high-quality materials that can withstand the rigors of hydraulic operation.

- Comprehensive Kit Look for rebuild kits that contain all necessary components. Some kits might skimp on essential parts, leading to incomplete repairs and the need for additional purchases.

- User Instructions A good rebuild kit should come with detailed instructions or diagrams that guide users through the rebuilding process, especially for those who may not have extensive mechanical knowledge.

Conclusion

In conclusion, hydraulic motor rebuild kits represent a practical solution for maintaining and restoring hydraulic motors to operational condition. They offer significant cost savings, support sustainability efforts, and can improve performance over time. By choosing the right rebuild kit, businesses can optimize equipment usage, ultimately enhancing productivity and reducing downtime in their operations. Regular maintenance and timely rebuilding can lead to a more reliable hydraulic system, making understanding and utilizing these kits an essential aspect of hydraulic motor management.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories